External pressure type hollow fiber film component and using method

A fiber membrane and external pressure technology, which is applied in the field of hollow fiber membrane module structure design, can solve the problems such as the great influence of membrane module water production, and achieve the effects of prolonging the filtration-cleaning cycle, improving filtration efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

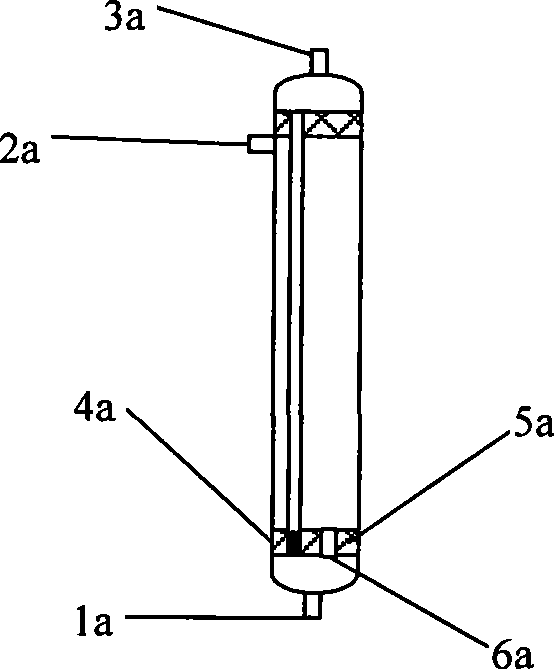

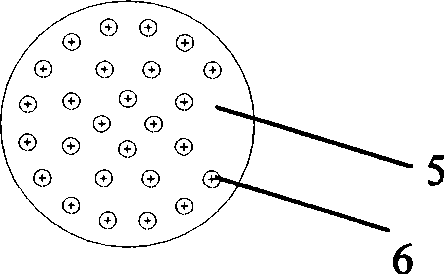

[0019] refer to figure 1 and 2 . In the existing membrane module, the raw liquid and cleaning air enter from the lower port 1a of the membrane module. At the end face 4a, the flow channel 6a on the epoxy resin 5a that is sealed and cast enters the membrane module, and the exhaust liquid and exhaust gas are discharged from the membrane module. The upper side port 2a is discharged, and the filtrate flows out from the upper port 3a of the membrane module.

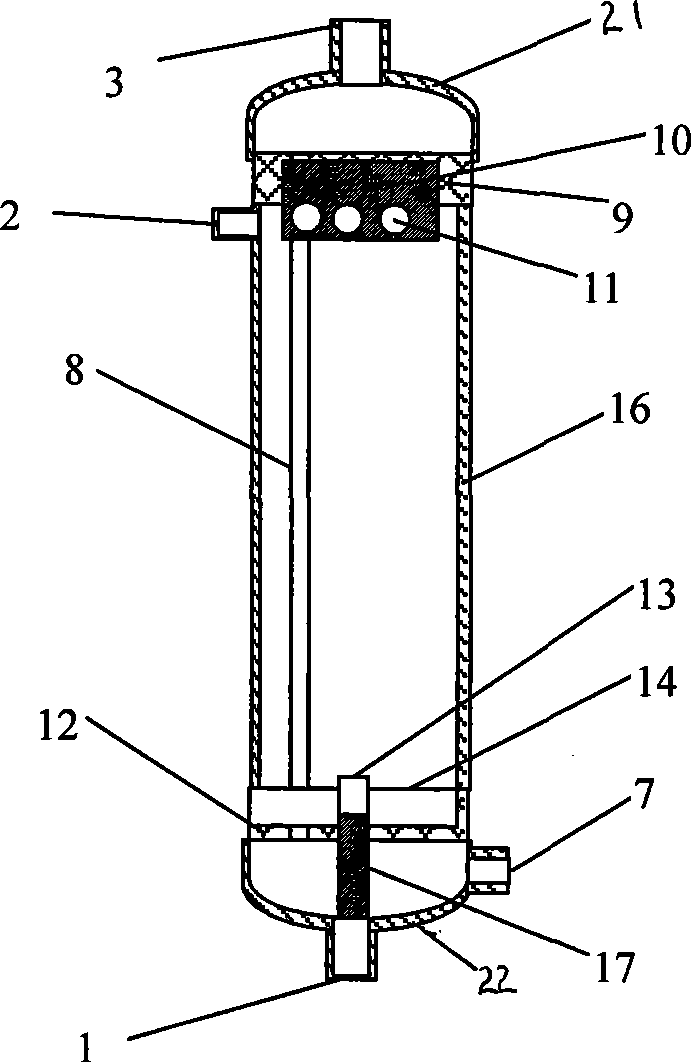

[0020] Refer to attached image 3 , 4 . It takes a membrane module with a straight shell as an example. The upper end of the housing 16 is cast with a first epoxy resin body 9, the lower end of the housing 16 is cast with a second epoxy resin body 12, the housing is provided with the hollow fiber membrane filament 8 in the membrane module, the hollow fiber in the membrane module The upper and lower ends of the membrane wire are respectively fixed on the first epoxy resin body 9 and the second epoxy resin body 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com