Molding method for cutting processing of pivoting support raceway

A slewing bearing and cutting technology, which is used in the field of double arc raceway and right-angle raceway cutting and forming, can solve the problems of huge program, unable to process normally, affecting the machining accuracy and surface quality of workpiece, etc., to improve production. Efficiency and product quality, avoiding tool breakage, machine vibration, and the effect of enhancing processing adaptability

Active Publication Date: 2010-08-11

NANJING GONGDA CNC TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The processing accuracy of the former depends entirely on the proficiency of the operator. The shape of the processed raceway is very random and the efficiency is very low, which cannot meet the production requirements of high quality and high efficiency.

The latter realizes automatic processing. Most manufacturers use software to automatically generate processing languages. Although they can eventually process products with high precision, there are a series of problems: slewing rings are typical series of products with basically the same structure and many models. If automatic programming is used, different models of products must be reprogrammed, prolonging the product development cycle and increasing development costs; the program implemented by automatic programming is huge, and it is difficult to find out the crux of the problem; automatic programming tool path, The cutting speed and cutting width have great randomness, and these parameters are required in actual processing, otherwise it is easy to cause the machine tool to vibrate during the processing, which seriously affects the processing accuracy and surface quality of the workpiece, and even makes the processing abnormal conduct

However, for a raceway of a certain size, if this method is used, the performance of the machine tool is very high, because the cutting area of the large raceway is large, the machine tool will bear a large cutting force, and it is easy to cause tool breakage, machine tool vibration, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Login to View More

Abstract

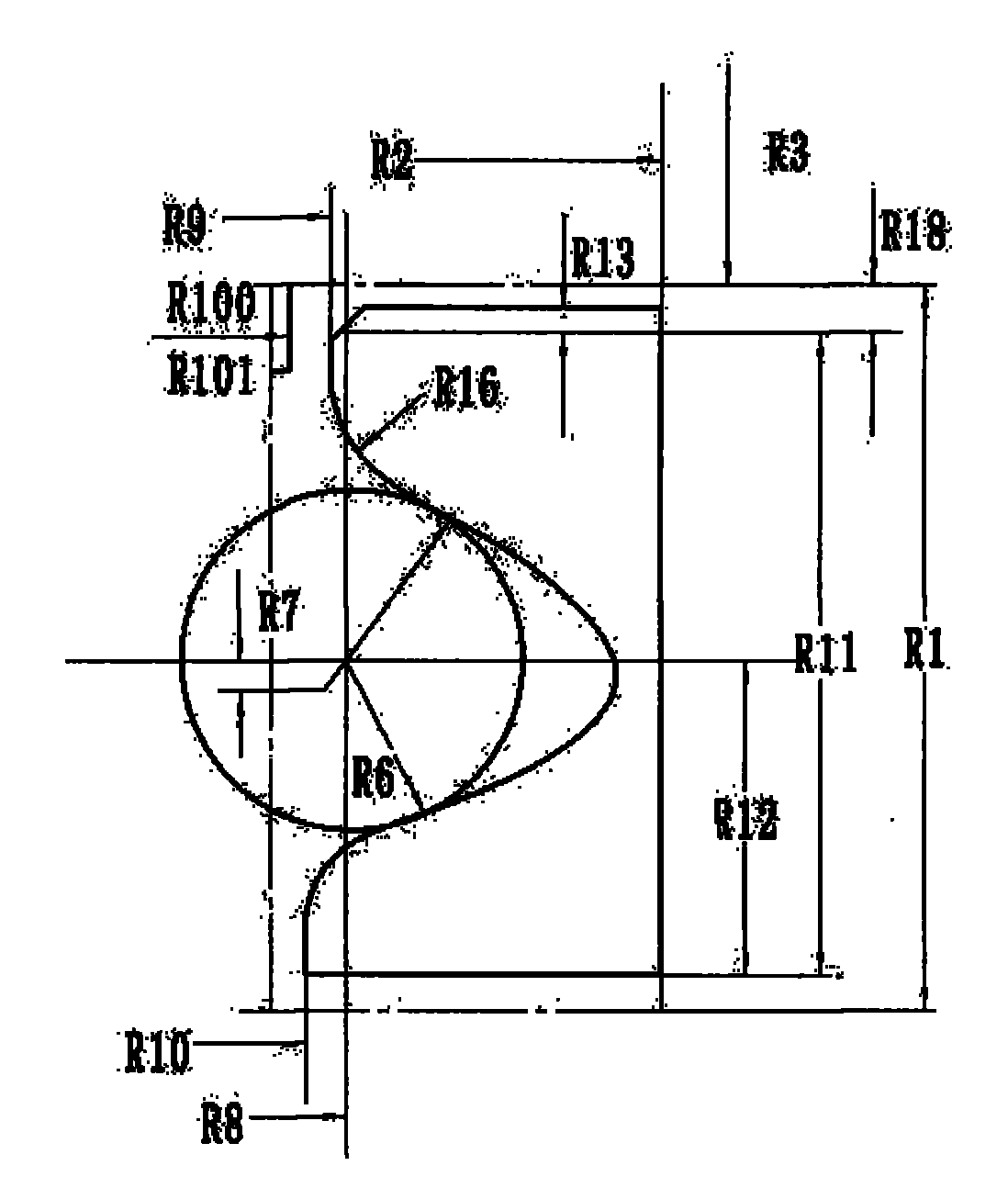

The invention provides a forming method used for cutting and processing a pivoting support raceway, which comprises bicircular-arc raceway processing and perpendicular raceway processing, wherein the bicircular-arc raceway processing comprises two steps: the first step comprises n cutting circulation (s), the cycle index n is equal to circular-arc radius R divided by each maximum feed amount L, wherein n is the positive integral equal to 1, 2, 3 and the like, each feed amount of circulating a circular-arc cutter along the axial direction of workpiece is n<2>-1* (R / n), each cutting amount of the circular-arc cutter along the radial direction of the workpiece can be enabled to be the same, the vast majority of metal in a forming arc-surface area on the workpiece is cut off in the first step, and the rest metal is cut to form an arc forming surface through adopting an envelope method in the second step; the perpendicular raceway processing adopts a turning tool with the angle of a cutterpoint less than 90 degrees, the cutter setting on the X direction and the Z direction is finished by combing an edge cutter-setting method, the perpendicular shape is then circularly cut off according to a certain cutting feed route, and the tool smoothing is carried out finally; and the cutting process of the pivoting support raceway is finished by combining macroinstruction programming. The forming method can ensure that the cutting space is less than an allowable value and avoid the problems of lathe vibration caused by cutter breaking, and the like.

Description

technical field The invention relates to a cutting and processing method for a raceway of a slewing bearing, in particular to a cutting and forming method for a double-arc raceway and a right-angle raceway on a numerically controlled vertical lathe. Background technique With the continuous growth of market demand for slewing bearings, the processing enterprises of slewing bearings are also trying their best to improve production efficiency. At present, there are two widely used processing methods: manual cutting of ordinary vertical lathes and automatic cutting of CNC vertical lathes. The processing accuracy of the former depends entirely on the proficiency of the operator. The shape of the processed raceway is very random and the efficiency is very low, which cannot meet the production requirements of high quality and high efficiency. The latter realizes automatic processing. Most manufacturers use software to automatically generate processing languages. Although they can ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23B1/00

Inventor 黄筱调洪荣晶方成刚邹辉

Owner NANJING GONGDA CNC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com