An array micro-groove micro-milling cutter

A micro-grooving and micro-milling technology, applied in milling cutters, milling machine equipment, metal processing equipment, etc., can solve the problem of difficult to meet the processing requirements of array micro-grooving with high efficiency, high consistency, and high surface integrity, and poor surface integrity of parts. , poor dimensional accuracy, etc., to achieve the effect of improving stiffness, high surface integrity, strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

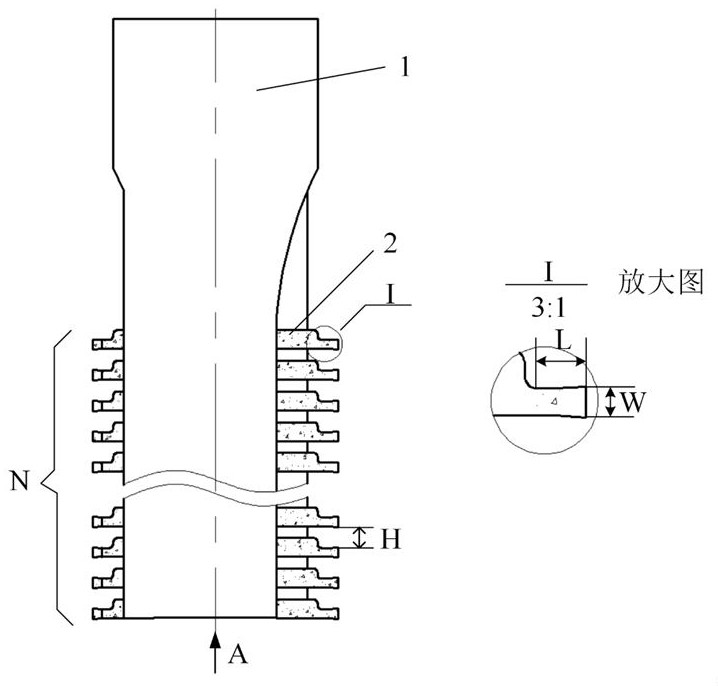

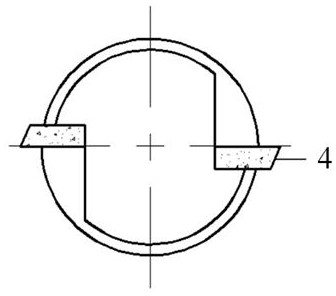

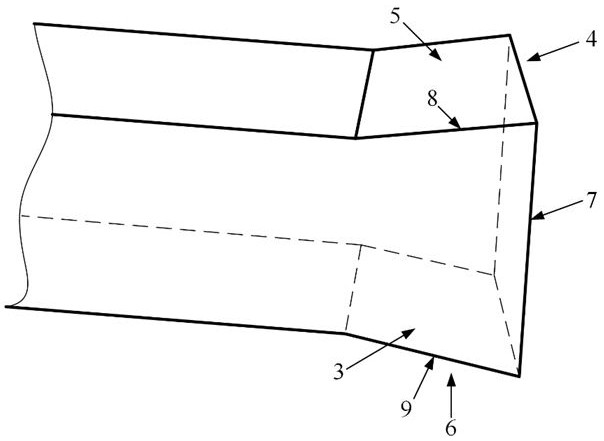

Embodiment 1

[0032] In this embodiment, microgroove width is 1mm, spacing is 1mm, and array microgroove number is 21. The diameter of tool holder 1 is 30mm, the main cutting edge width is 1mm, the effective milling length is 1mm, and the blade spacing is 1mm. The number of inserts in a single row is 3, the angle between the main flank 4 and the rake face 3 is an acute angle, and the main rake angle, auxiliary rake angle I, auxiliary rake angle II, auxiliary relief angle I and auxiliary relief angle II are all 0 °, the main relief angle is 8°, the handle material is made of carbide, and the blade is made of PCD material.

Embodiment 2

[0034] In this embodiment, the microgroove width is 0.5mm, the spacing is 0.5mm, and the number is 100 array microgrooves. The diameter of the tool holder 1 is 15mm, the main cutting edge width is 0.5mm, and the effective milling length is 0.5mm. The pitch is 0.5mm, the number of inserts in a single row is 50, the included angle between the main flank 4 and the rake face 3 is an acute angle, the main rake angle, the auxiliary rake angle I, the auxiliary rake angle II, the auxiliary relief angle I and the auxiliary flank The angle II is 0°, the main relief angle is 10°, the handle material is made of carbide, and the blade is made of PCD material.

Embodiment 3

[0036] In this embodiment, microgroove width is 0.05mm, spacing is 0.05mm, and array microgroove number is 100. The diameter of tool holder 1 is 5mm, the main cutting edge width is 0.05mm, and the effective milling length is 0.1mm. The pitch is 0.05mm, the number of inserts in a single row is 100, the angle between the main flank 4 and the rake face 3 is an acute angle, the main rake angle, auxiliary rake angle I, auxiliary rake angle II, auxiliary relief angle I and auxiliary flank The angle II is 0°, the main relief angle is 15°, the handle material is made of carbide, and the blade is made of CBN material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com