Water-soluble aluminum and aluminum alloy soft soldering brazing flux as well as preparation method thereof

A kind of aluminum alloy, soldering technology, applied in welding equipment, metal processing equipment, welding medium and other directions, can solve the problem of poor welding effect, etc., to achieve the effect of high activity, strong process adaptability and strong wetting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

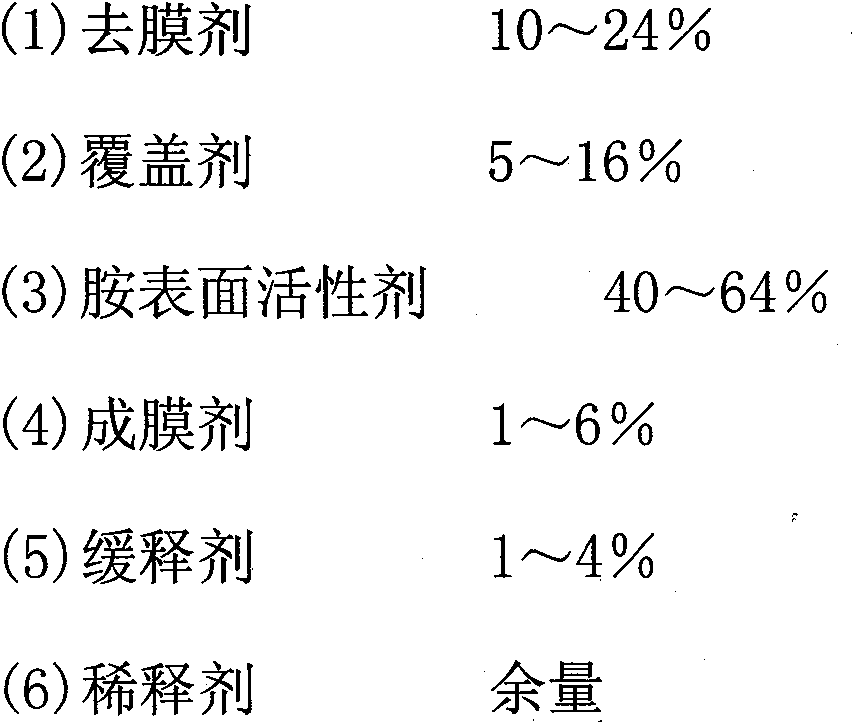

Method used

Image

Examples

Embodiment 1

[0041] (1) Ammonium fluoroborate 15%

[0042] (2) Zinc chloride 8%

[0043] (3) Stannous chloride 6%

[0044] (4) Triethanolamine 32%

[0045] (5) Hydroxyethylethylenediamine 30%

[0046] (6) Absolute ethanol 10%

[0047] (7) Isopropanol 7%

[0048] (8) Benzotriazole 2%

[0049] (9) 301 resin 2%

[0050] Preparation method: Add ammonium fluoroborate, zinc chloride, and stannous chloride to an amine solvent, and stir continuously at 85°C for 32 minutes to fully dissolve and mix the raw materials. After the solvent is cooled to 40°C, add anhydrous Ethanol, isopropanol, benzotriazole and 301 resin were stirred evenly, and the soldering flux was obtained by standing and filtering.

Embodiment 2

[0052] (1) Ammonium fluoroborate 20%

[0053] (2) Zinc stearate 10%

[0054] (3) Stannous octoate 8%

[0055] (4) Monoethanolamine 22%

[0056] (5) NN-Dimethyldodecylamine 30%

[0057] (6) Absolute ethanol 15%

[0058] (7) Benzotriazole 3%

[0059] (8) 302 resin 2%

[0060] Preparation method: Add ammonium fluoroborate, zinc stearate, and stannous octoate into monoethanolamine and NN-dimethyldodecylamine solvent, and stir continuously at 75°C for 35 minutes to fully dissolve and mix the raw materials; After cooling to 35°C, add absolute ethanol and stir evenly, then stand and filter to obtain the aluminum soldering flux.

Embodiment 3

[0062] (1) Ammonium fluoroborate 8%

[0063] (2) Zinc fluoride 10%

[0064] (3) SnF2 8%

[0065] (4) NN-Dimethyldodecylamine 25%

[0066] (5) Diethylenediamine 30%

[0067] (6 absolute ethanol 18%

[0068] (7) Isopropanol 12%

[0069] (8) Imidazoline 1%

[0070] (9) 302 resin 3%

[0071] Preparation method: Add ammonium fluoroborate, zinc fluoride, and stannous fluoride into NN-dimethyldodecylamine and diethylenediamine solvent, and stir continuously at 70°C for 30 minutes to fully dissolve and mix the raw materials. After the solvent is cooled to 32°C, add absolute ethanol, isopropanol, imidazoline and 302 resin and stir evenly, then stand and filter to obtain the aluminum soldering flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com