Offset press printing ink working temperature controller

A technology for working temperature and control devices, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve problems such as ink supply, ink distribution, bad influence of ink, ink printing quality decline, failure to start work, etc., to achieve technical The scheme is simple and easy to implement, the quality is improved, and the effect of heating/cooling is balanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

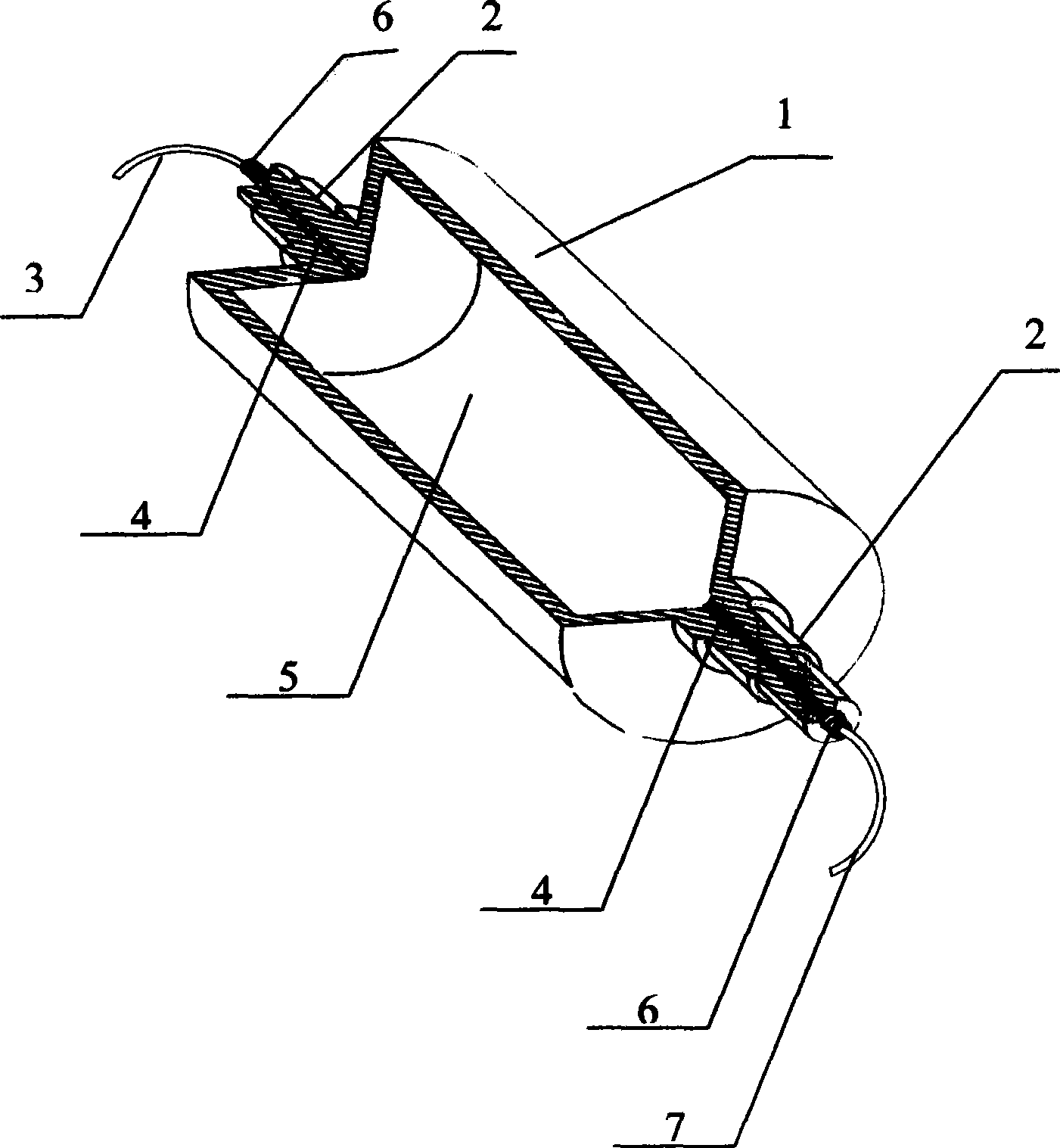

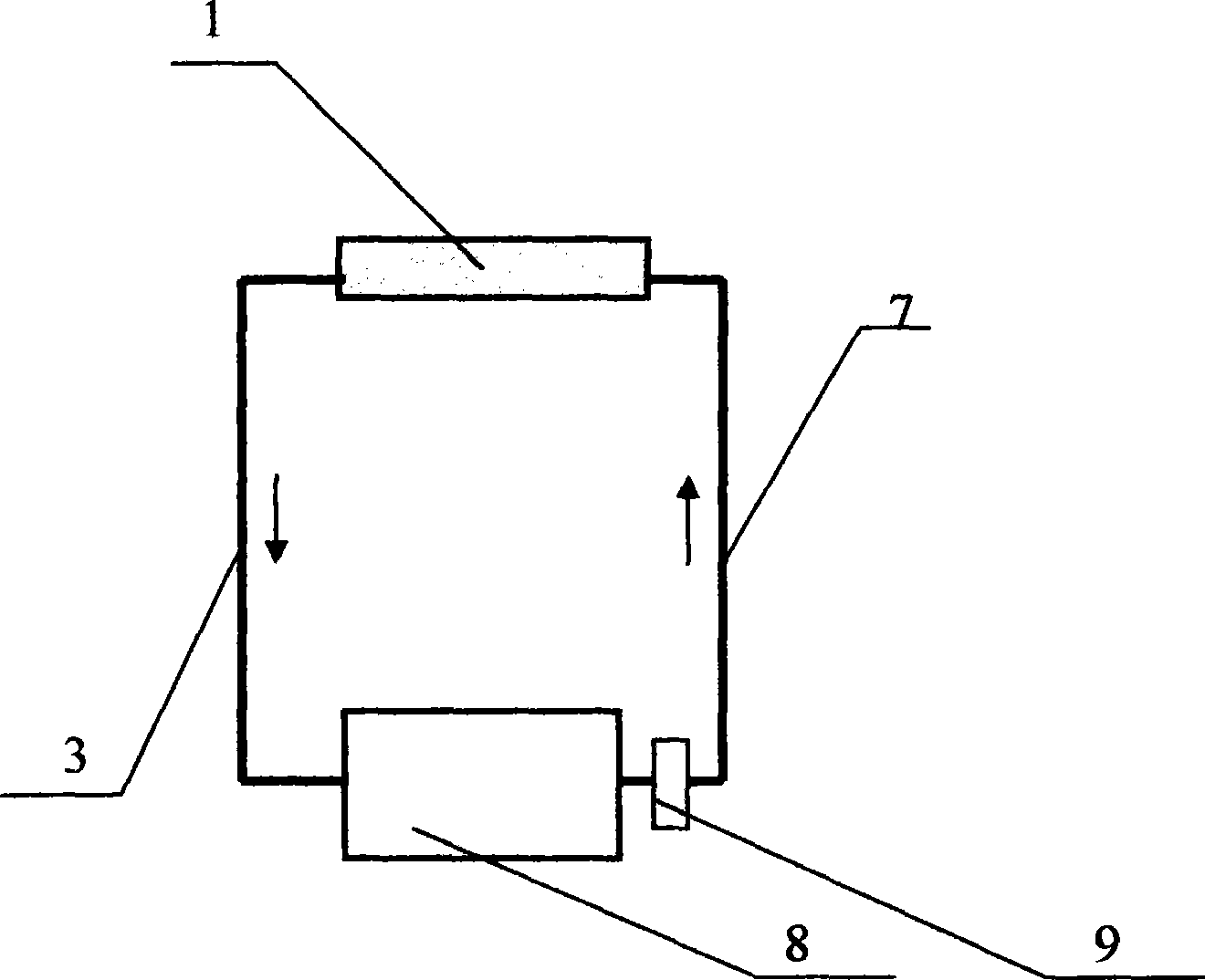

[0011] see figure 1 , 2 , to reflect the specific structure of the present invention, the middle part of the working shaft of the ink roller central shaft 1 is provided with a heat transfer oil chamber 5, and the middle part of the rotating shaft 2 at both ends of the ink roller central shaft 1 is provided with a channel 4 to communicate with the heat transfer oil chamber 5. The other end of the channel 4 communicates with the heat transfer oil input pipe 7 and the output pipe 3 respectively through the rotary seal 6, the heat transfer oil input pipe 7 is connected to the output end of the heat transfer oil heating / cooling device 8 through the heat transfer oil pump 9, and the heat transfer oil output The pipe 3 is connected to the input end of the heat transfer oil heating / cooling device 8 .

[0012] According to the ratio of parts by weight: 85 parts of pure water, 13 parts of ethanol, and 2 parts of sodium chloride. The above-mentioned components are mixed according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com