Floating berth loading and unloading system

A loading and unloading system and berthing technology, applied in floating buildings, ships, etc., can solve the problems of difficult large-scale development, poor economic benefits, long construction period, etc., to attenuate motion energy, reduce displacement values in all directions, and improve survival effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

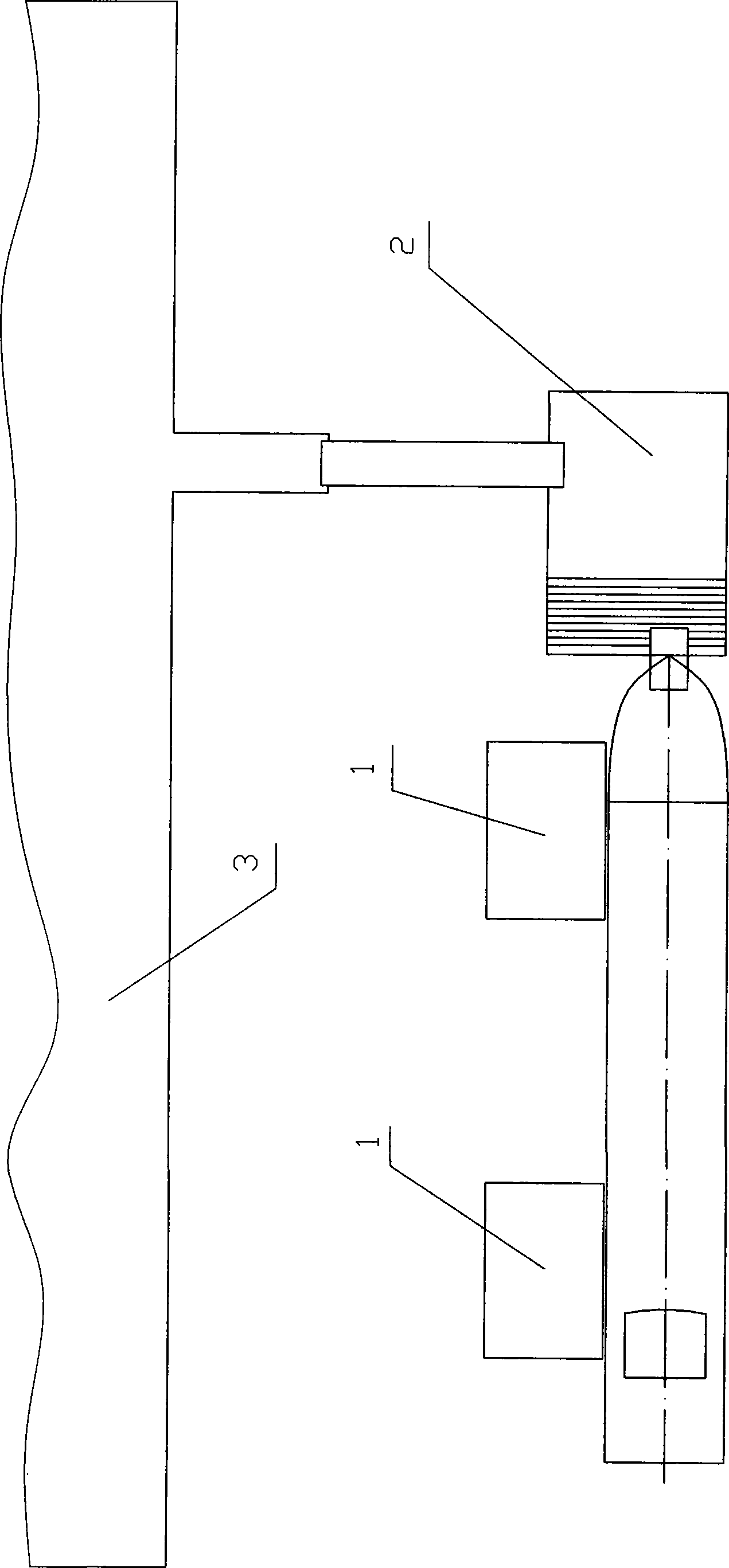

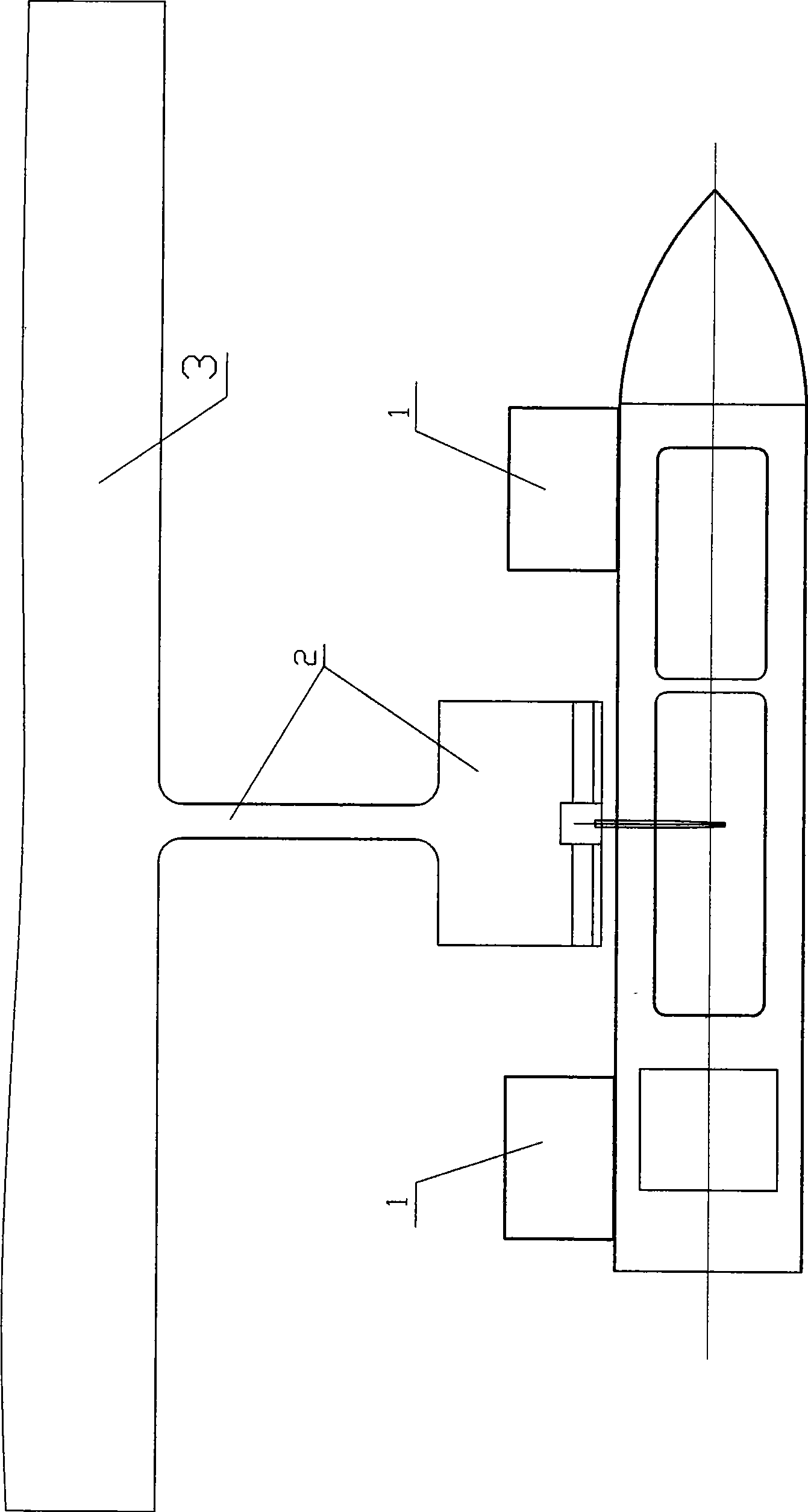

[0012] Such as Figure 2~4 As shown: the floating berthing loading and unloading system of the present invention includes a fixed operating platform 2, and is characterized in that it also includes several groups of floating berthing piers 1, and the floating berthing piers can be arranged on one side or both sides of the fixed operating platform. side.

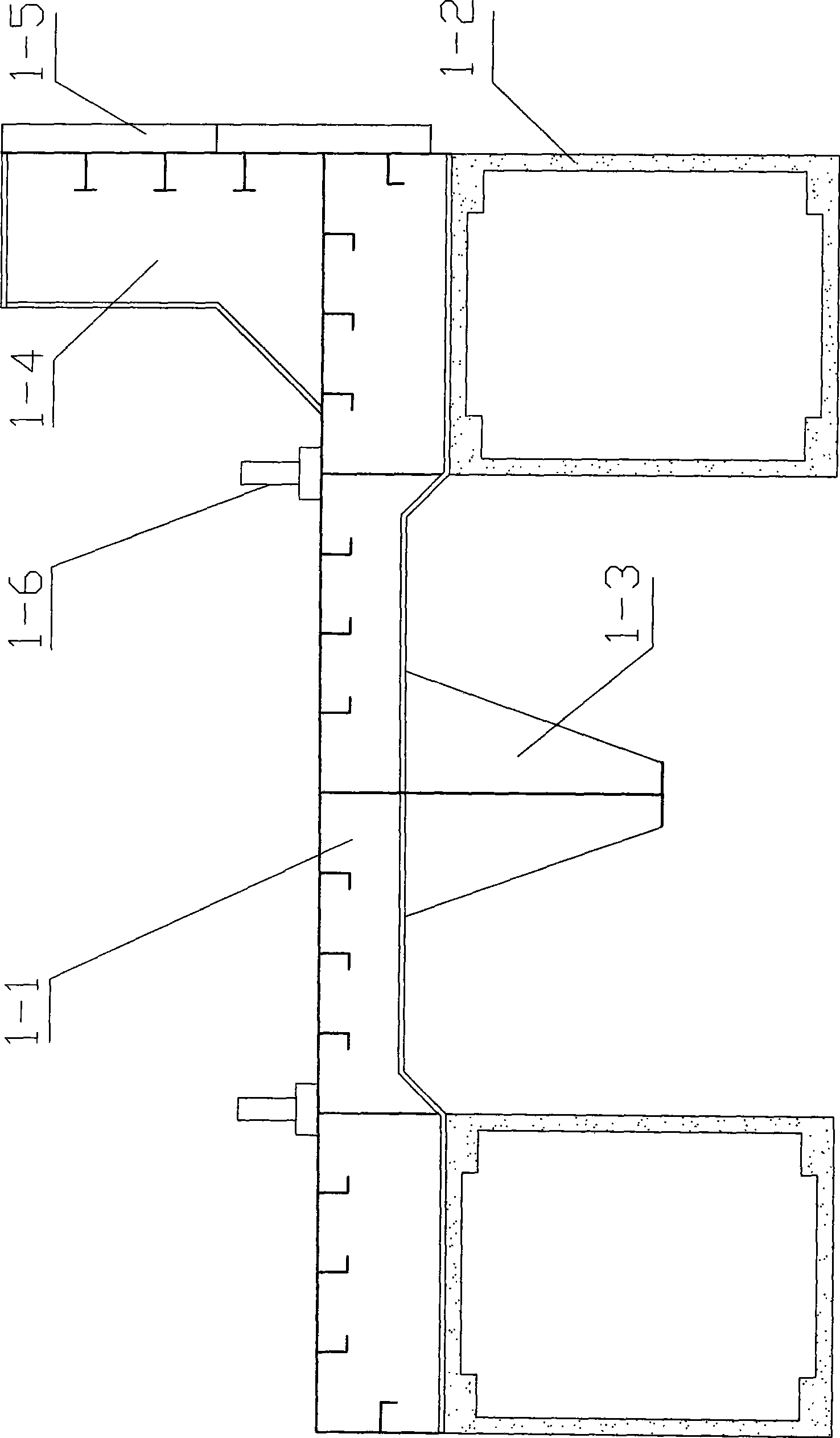

[0013] Such as figure 1 As shown: the floating mooring pier is composed of superstructure 1-1, lower buoyancy tank 1-2, hydrodynamic damping device 1-3, berthing components 1-4, radial multi-point mooring equipment 1-6, and the superstructure is The beam-like structure is the same as the prior art; there are two or more lower pontoons under the upper structure, and the buoyancy of the lower pontoons keeps the upper structure above the water level; between two lower pontoons Equipped with a hydrodynamic damping device, the hydrodynamic damping device is located under the upper structure. By setting the hydrodynamic damping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com