Drilling method for steam assisted gravity draining oil well

An auxiliary gravity and oil drainage technology, which is applied in the direction of wellbore/well components, earthwork drilling, production fluid, etc., can solve the problems of prone to steam channeling, plugging of production wells, affecting recovery rate, etc., and achieve the goal of reducing relative errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

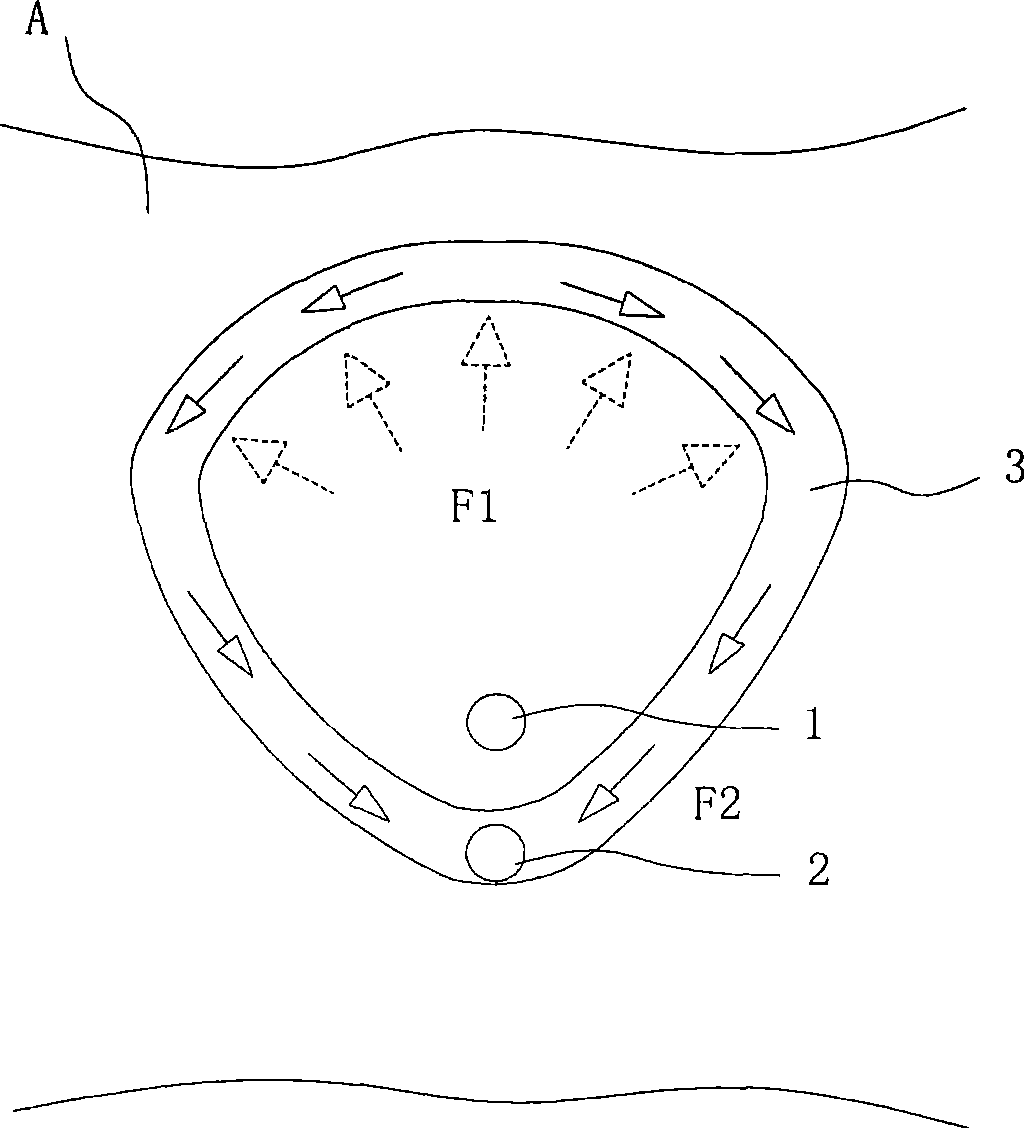

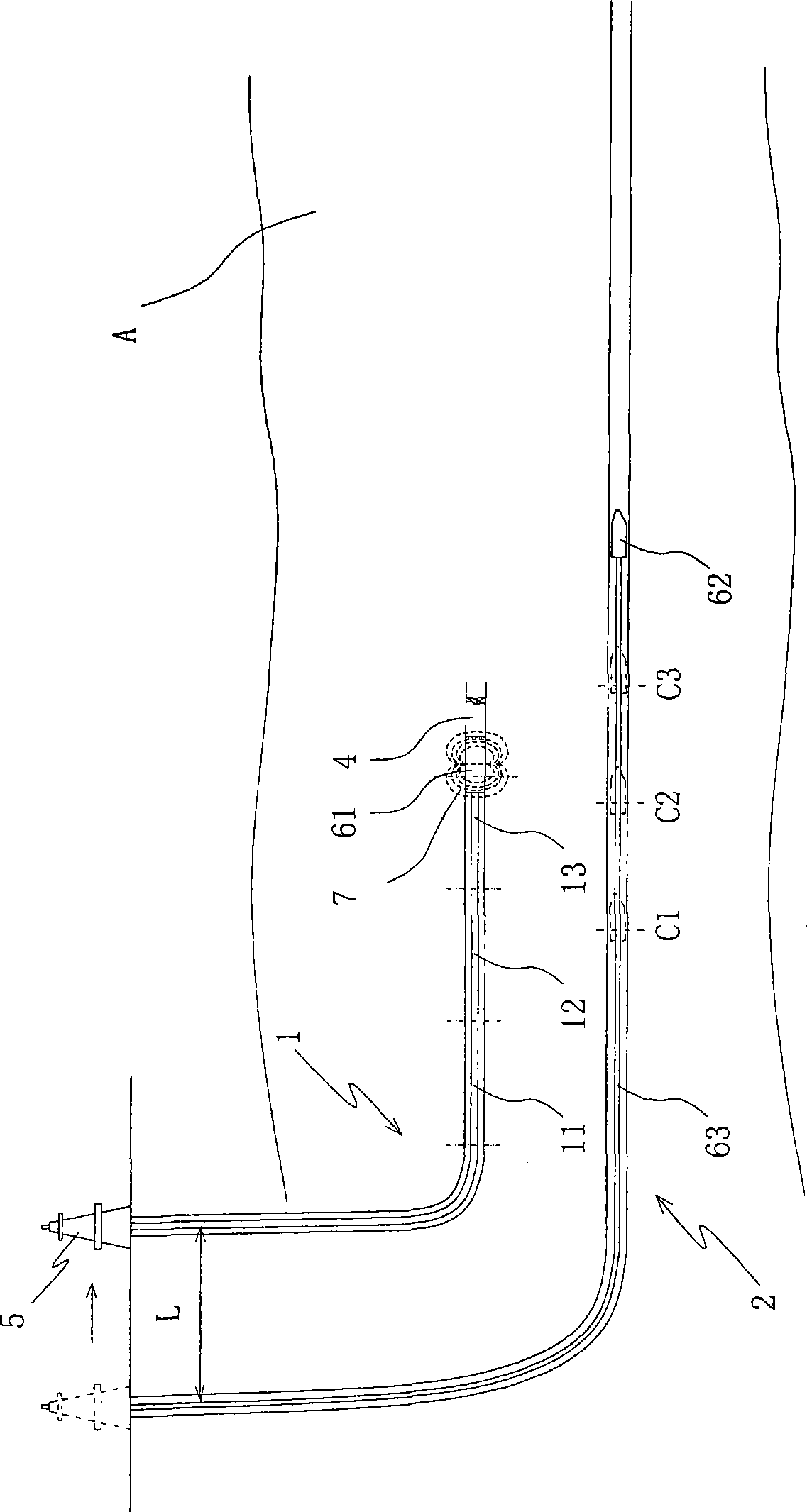

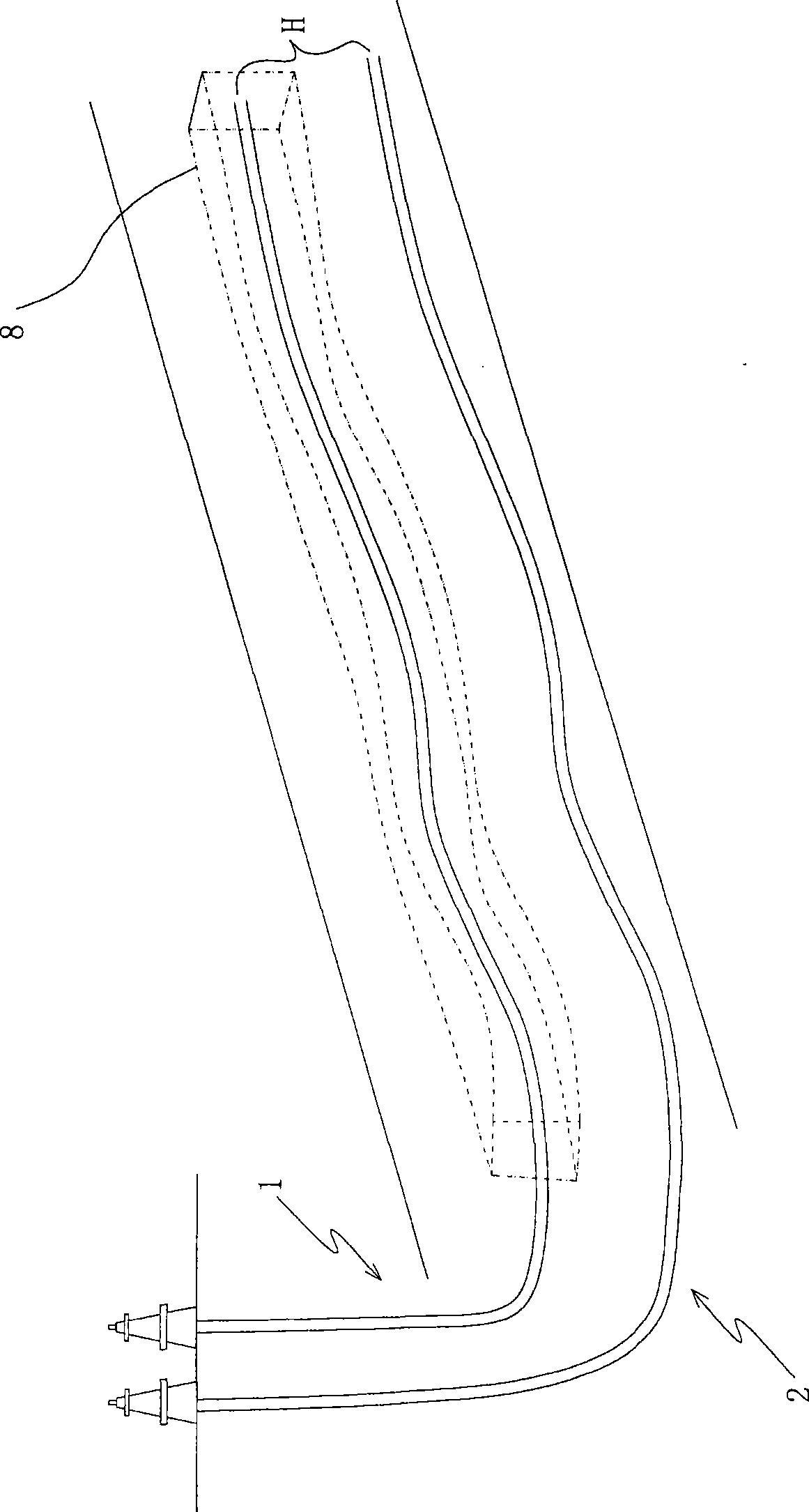

[0017] Such as figure 2 As shown, the present invention provides a drilling method for steam-assisted gravity drainage oil wells, which are used to drill two parallel horizontal wells at the bottom of the reservoir A, the upper horizontal well is the gas injection well 1, and the lower horizontal well is the gas injection well 1. The flat well is the production well 2, and the specific steps include:

[0018] 1. First drill the production well 2 below. Drilling single well technology is relatively mature. Drilling tools with measurement-while-drilling systems can be used in conventional methods to easily ensure that the absolute error of production wells is within the allowable range. The specific operation process is: Drill a certain length of vertical well section, Afterwards, build-up drilling, drill a 20-meter or so inclined vertical well section at an inclination angle of about 55 degrees, which is convenient for lowering the oil production pump, and then continue to bu...

Embodiment approach 2

[0028] The specific steps, principles and effects of this embodiment are basically the same as those of Embodiment 1, except that the drilling sequence of the two wells has changed. In this embodiment, the steam injection well is drilled first, and then the production well is drilled Well, other contents will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com