Oil pump of flushing well

A technology of well pump and pump barrel, applied in the field of well-flushing oil pump, can solve the problems of reducing pump efficiency air lock, shortening the effective stroke, damage, etc., and achieving the effect of increasing the filling factor, increasing the effective stroke, and reducing fatigue loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

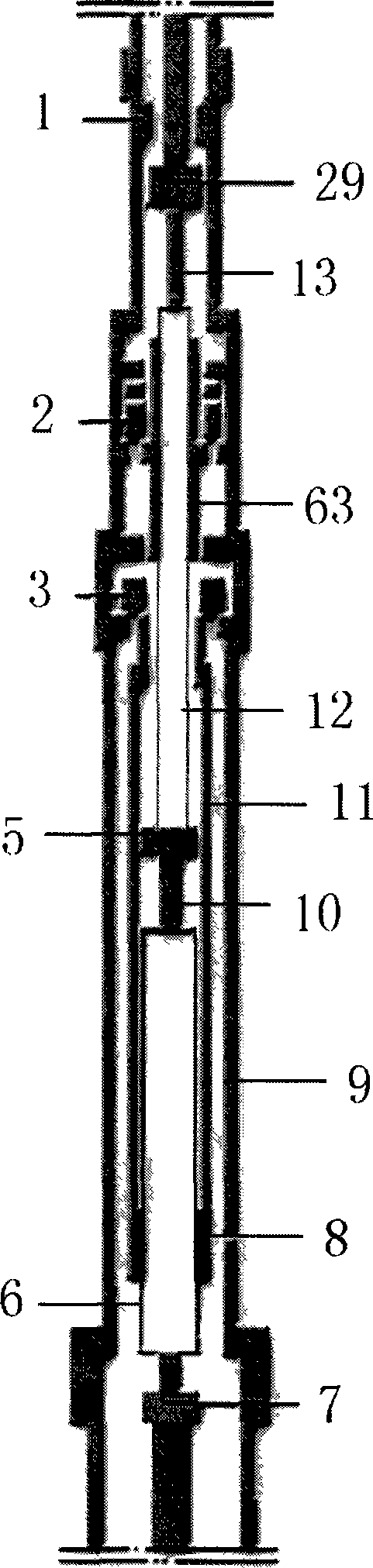

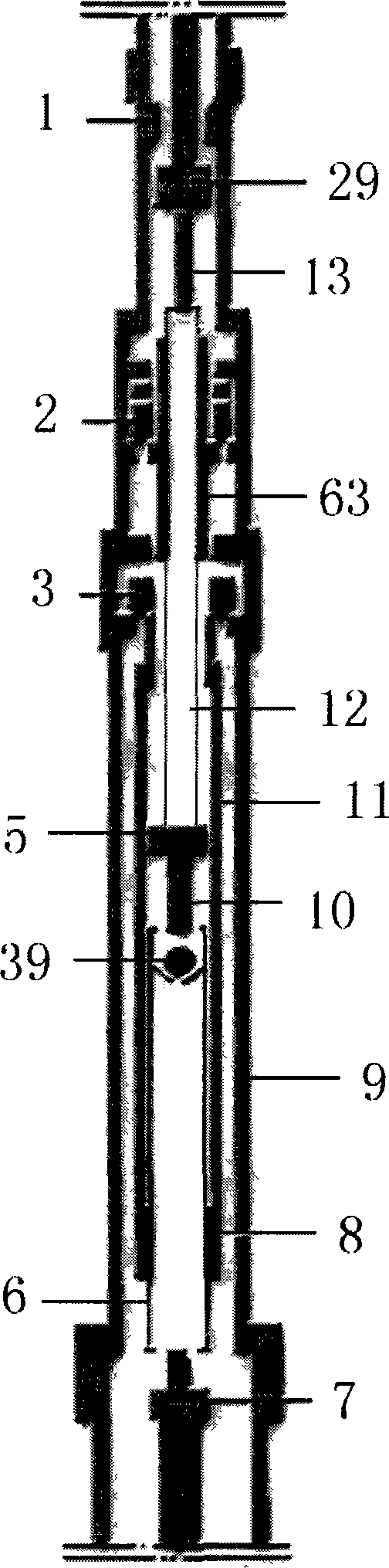

[0009] exist figure 1 Among them, release joint 1, oil outlet valve 2, upper pump barrel 63, oil inlet valve 3, outer pump tube 9, inner pump tube 11, and lower pump barrel 8 are sequentially connected to form the inlet and outlet channels of the pump; 29. The upper reducing rod 13, the upper plunger 12, the limit joint 5, the lower reducing rod 10, the lower plunger 6, and the weighting rod 7 are sequentially connected to form the suction mechanism of the pump. The length of the upper plunger 12 is greater than the stroke length of the pump relative to the length of the upper pump barrel 63 and the length of the lower plunger 6 relative to the lower pump barrel 8 . During the upstroke, the suction mechanism moves upwards, increasing the pressure in the annular space between the inner pump barrel 11 and the upper plunger 12, forcing the oil inlet valve 3 to close, and the oil outlet valve 2 to open, and the liquid in the pump is discharged to the ground; During the downstroke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com