Calibration method for image measuring system

A calibration method and image measurement technology, applied in the direction of camera devices, etc., can solve the problems of not being able to accurately calibrate the relationship between the observed object and the image, not obtaining the physical coordinates of the calibration point, etc., to meet the real-time requirements, small footprint, high The effect of precision calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

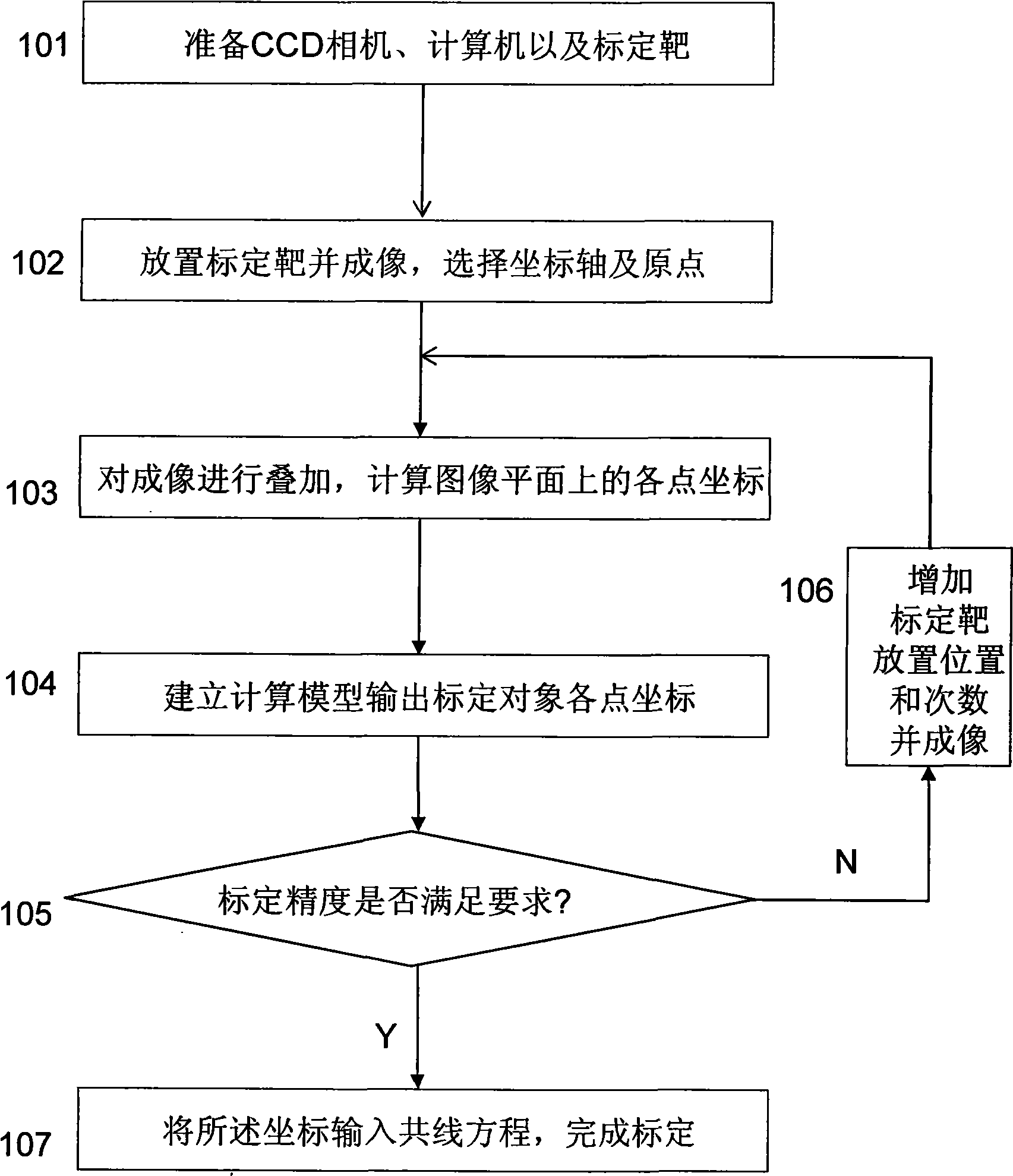

[0040] refer to figure 1 , a method for calibrating an image measurement system according to the present invention, comprising the following steps:

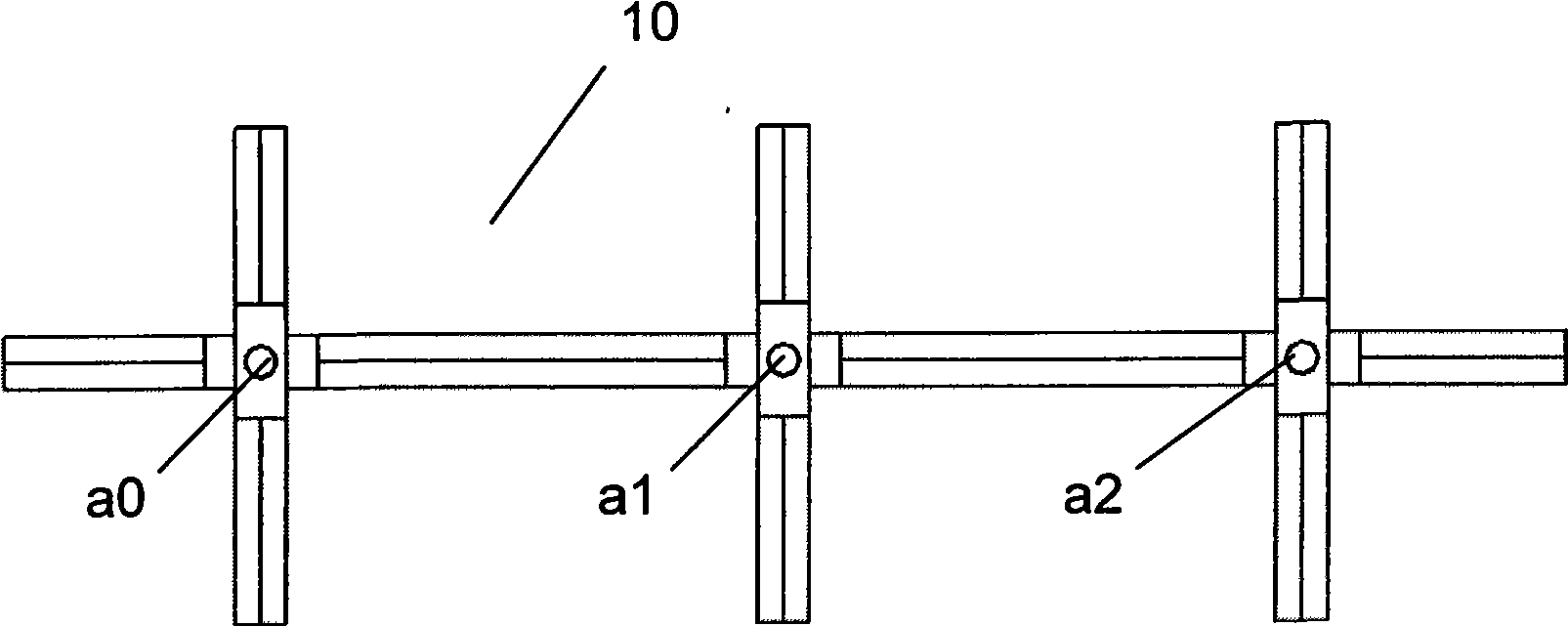

[0041] 101. Prepare the CCD camera 20, the computer 30 and the calibration target 10. The computer 30 is connected with the CCD camera 20, the calibration target 10 has calibration points a0, a1, a2, and the calibration points a0, a1, a2 are on the same horizontal line and keep a fixed distance between them, refer to figure 2 and Figure 5 .

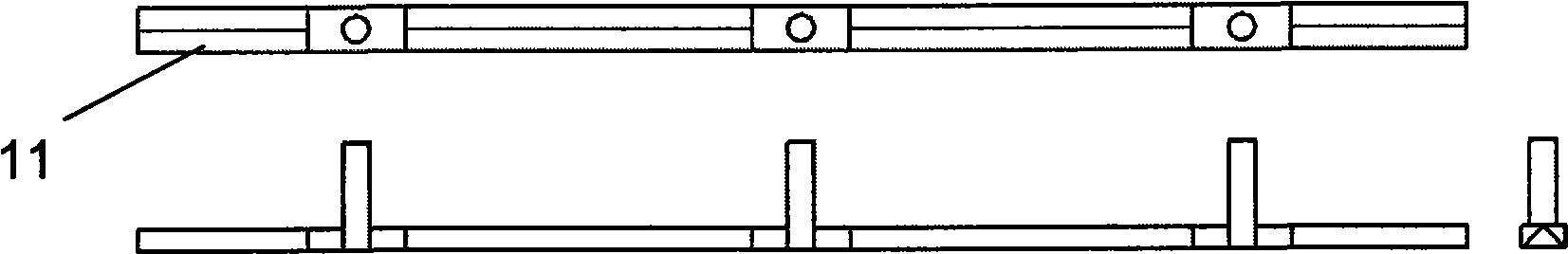

[0042] The calibration target 10 includes a body 11 and three rotatable feet 12, the rotatable feet 12 are installed on the centerline of the body 11 through a reference axis, and the center points a0, a1, a2 of the three reference axes on the centerline as the calibration point, refer to figure 2 .

[0043]The bottom surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com