Arrangement comprising a shunt resistor and method for producing the same

A shunt resistor and resistance zone technology, applied in resistor cooling/heating/ventilation devices, resistors, circuit devices, etc., can solve the problems of decreased soldering function, high temperature of shunt resistors, and delamination of shunt resistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

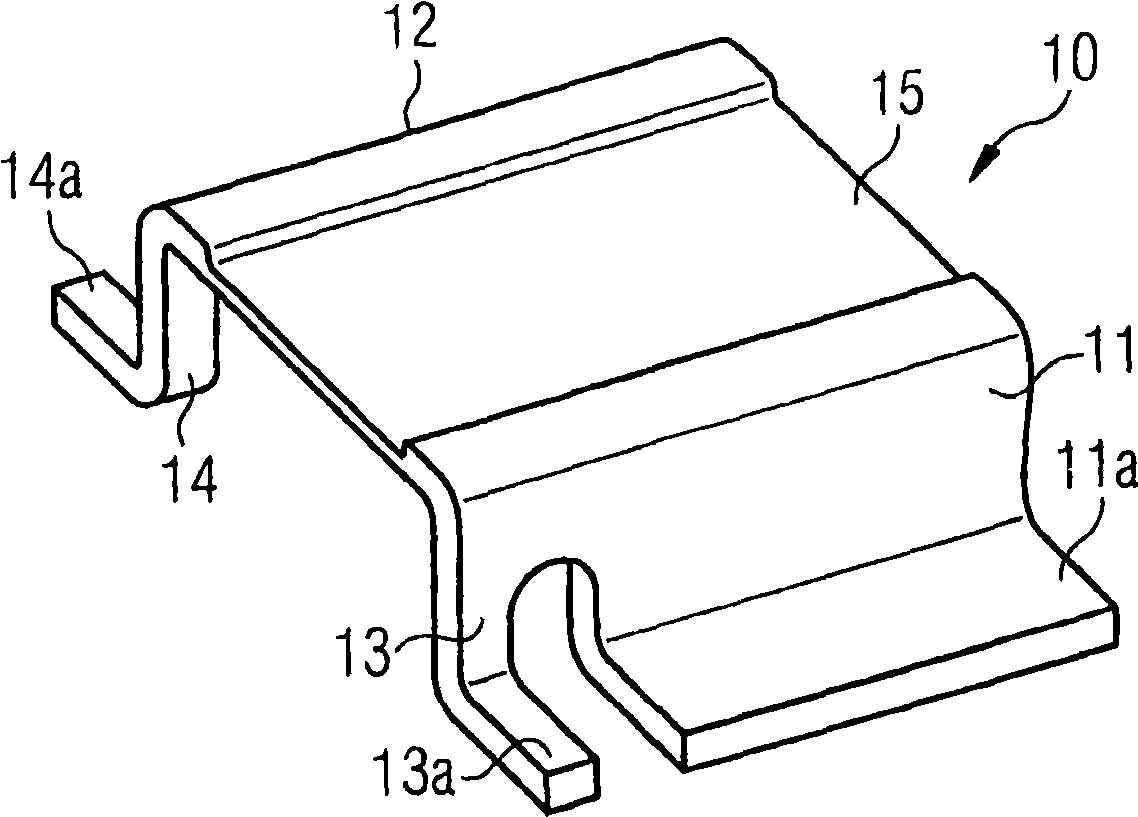

[0026] figure 1 is a perspective view of an example of a shunt resistor 10 . The shunt resistor 10 includes a first connection pin 11 , a second connection pin 12 , an optional third connection pin 13 and an optional fourth connection pin 14 . Each of the terminal pins 11, 12, 13, 14 includes a flange 11a, 12a (hidden in the figure 1 Middle), 13a and 14a. Between the first connection pin 11 and the second connection pin 12 and between the third connection pin 13 and the fourth connection pin 14 is arranged a resistance zone 15 with a predetermined resistance value. Compared with the resistance area 15, the first connecting pin 11 and the second connecting pin 12 have a low resistance value. For the resistance region, for example, a metal alloy having a low relationship between heat and resistivity can be used. Examples of alloys already available in the market are, (comprising, for example, about 82% to 84% by weight of copper, 12% to 15% by weight of manganese and 2% to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com