Contactor component of vacuum breaker

A technology for vacuum circuit breakers and contactors, applied in high-voltage air circuit breakers, scattered finger contacts, circuits, etc., can solve the problems of degradation and damage of main circuit terminals and contactor fingers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Referring now to the accompanying drawings, a detailed description of the present invention will be given.

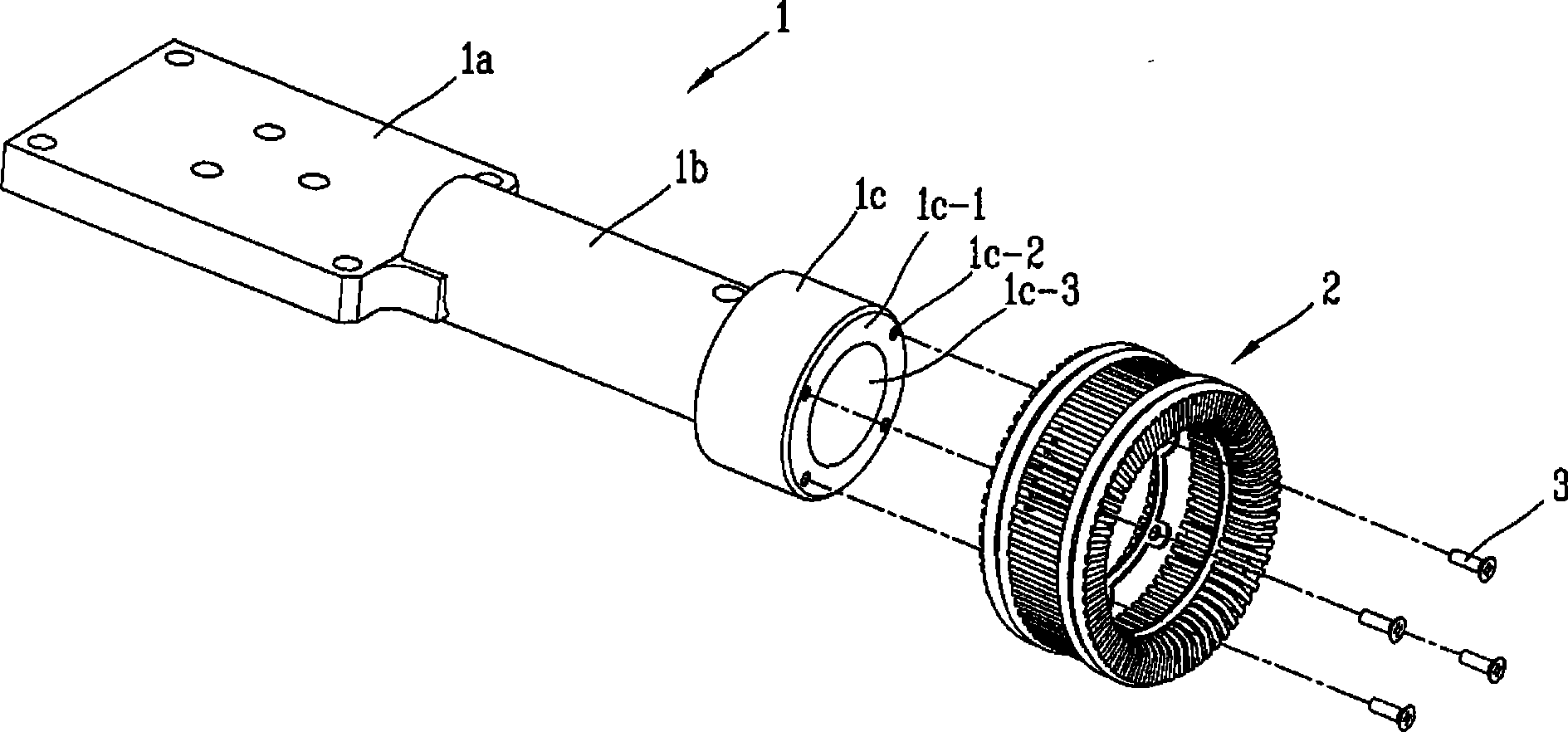

[0022] figure 1 It is an exploded perspective view of a main circuit terminal and a contactor assembly of a vacuum circuit breaker according to the present invention.

[0023] exist figure 1 With reference to , the state of use of the contactor assembly of the vacuum circuit breaker according to the present invention will be described.

[0024] refer to figure 1 , reference numeral 1 denotes a main circuit terminal in a vacuum circuit breaker. The main circuit terminal includes: a bus bar portion 1a configured to have a plate-like electrical conductor connected to a main circuit portion (not shown) by connecting means such as bolts; an electric conductor from which the busbar portion extends; and a tubular end portion 1c integrally formed at the end of the columnar extension portion 1b and having an enlarged diameter. Herein, the tubular end 1c comprises: a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com