Motor for dust collector

A technology for vacuum cleaners and casings, which is applied in the fields of vacuum cleaner motors and heat dissipation structures, can solve the problems of complex structure and poor heat dissipation effect, and achieves the effects of good cooling effect, small gap and improved heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

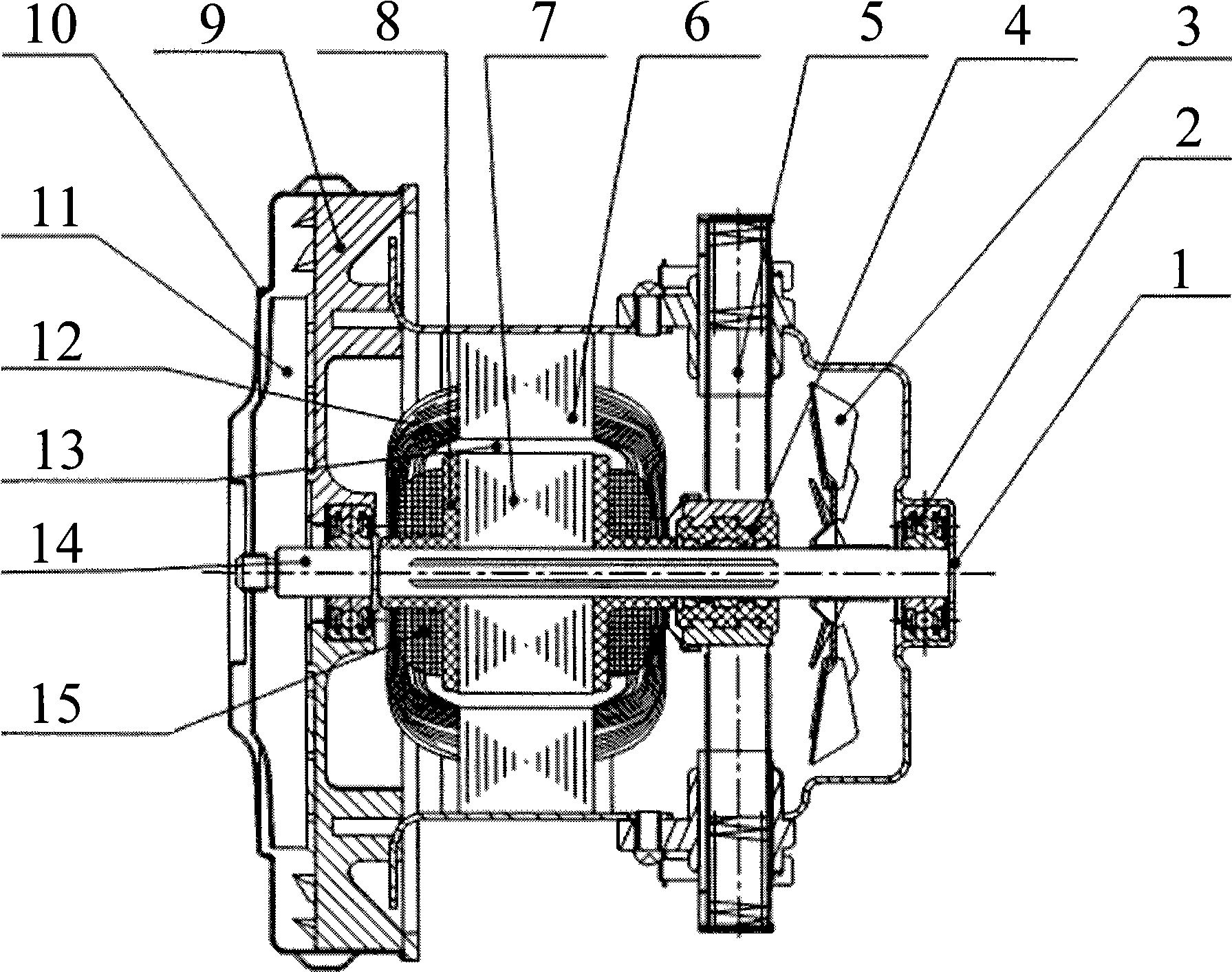

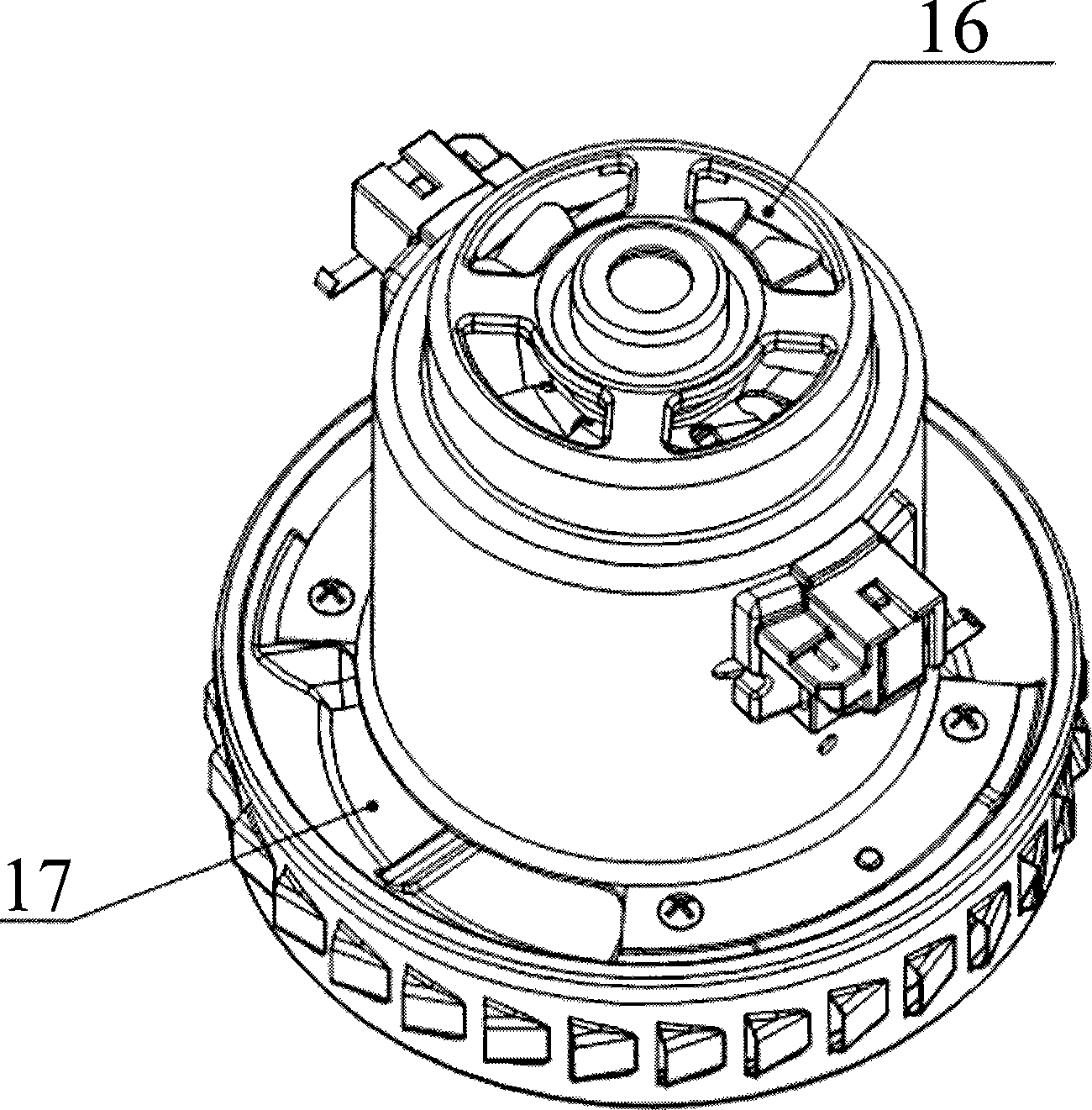

[0019] Such as figure 1 As shown, the wet and dry dual-purpose vacuum cleaner motor includes a stator core 6, a rotor core 7, a fixed impeller 9, a wind cover 10, a moving impeller 11, a stator winding 12, a rotor winding 15 and an insulating end plate 8. In the stator core A stator-rotor air gap 13 is formed between 6 and the rotor core 7 . The cooling fan 3 is arranged between the bearing 2 and the commutator 4, and is fixed on the output shaft 14. There is a gap between the outer edge of the fan blade of the cooling fan 3 and the inner peripheral wall of the casing 1, and the gap is as small as possible. , take 0.5 ~ 2mm. In addition, the axial distance between the cooling fan 3 and the commutator 4 is much larger than the axial distance between the cooling fan 3 and the bearing 2 . Such as figure 2 , have an air inlet 16 at the end of the casing 1, and have an air outlet 17 at the round mouth of the casing. When the cooling fan 3 is running at high speed, the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com