Spindle for a motion gear

A transmission device and spindle technology, which is applied in the directions of transmission device, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of the design structure of the driving mechanism without specifying the air ring limiter, and the lack of specifying the air ring limiter in detail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

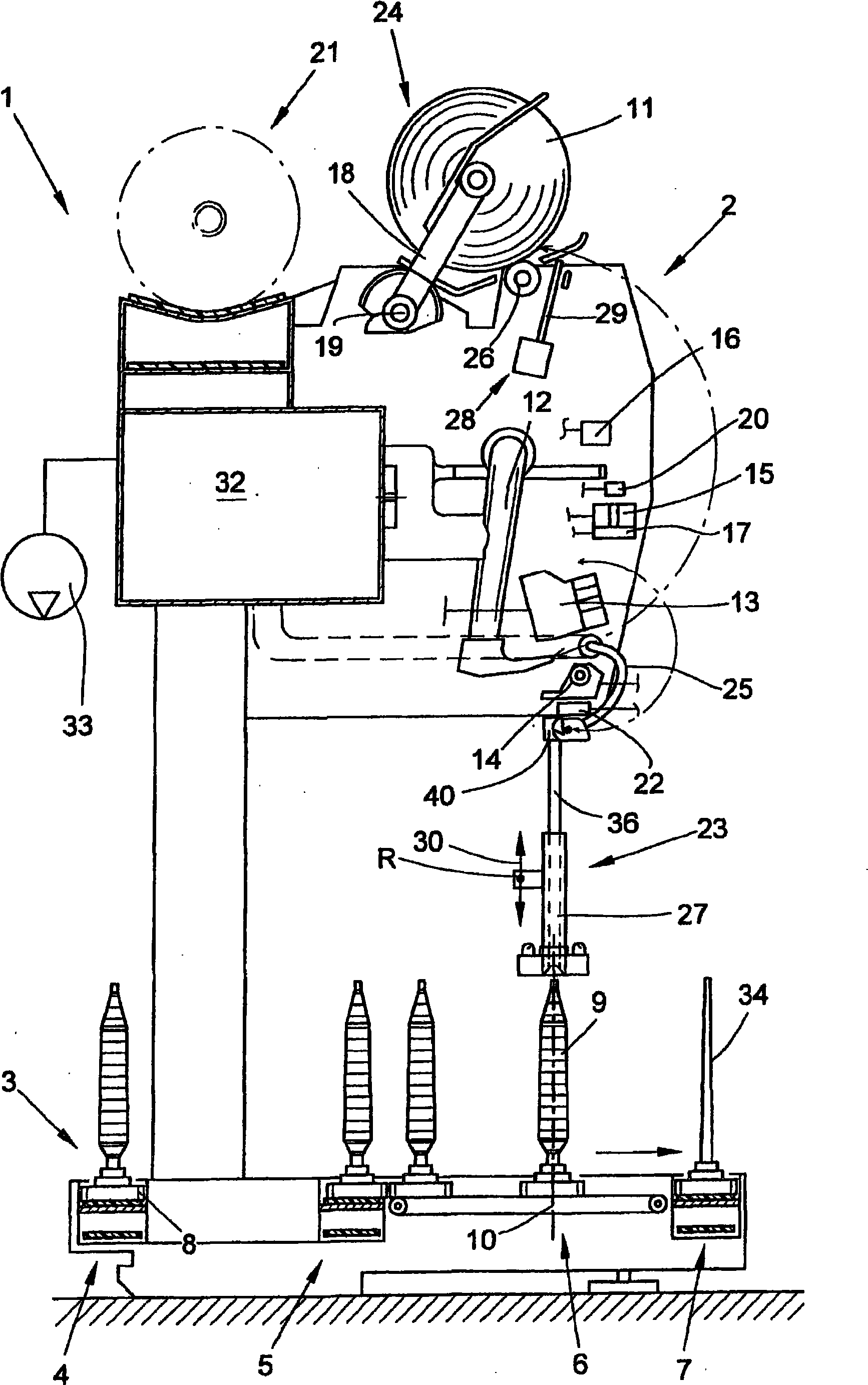

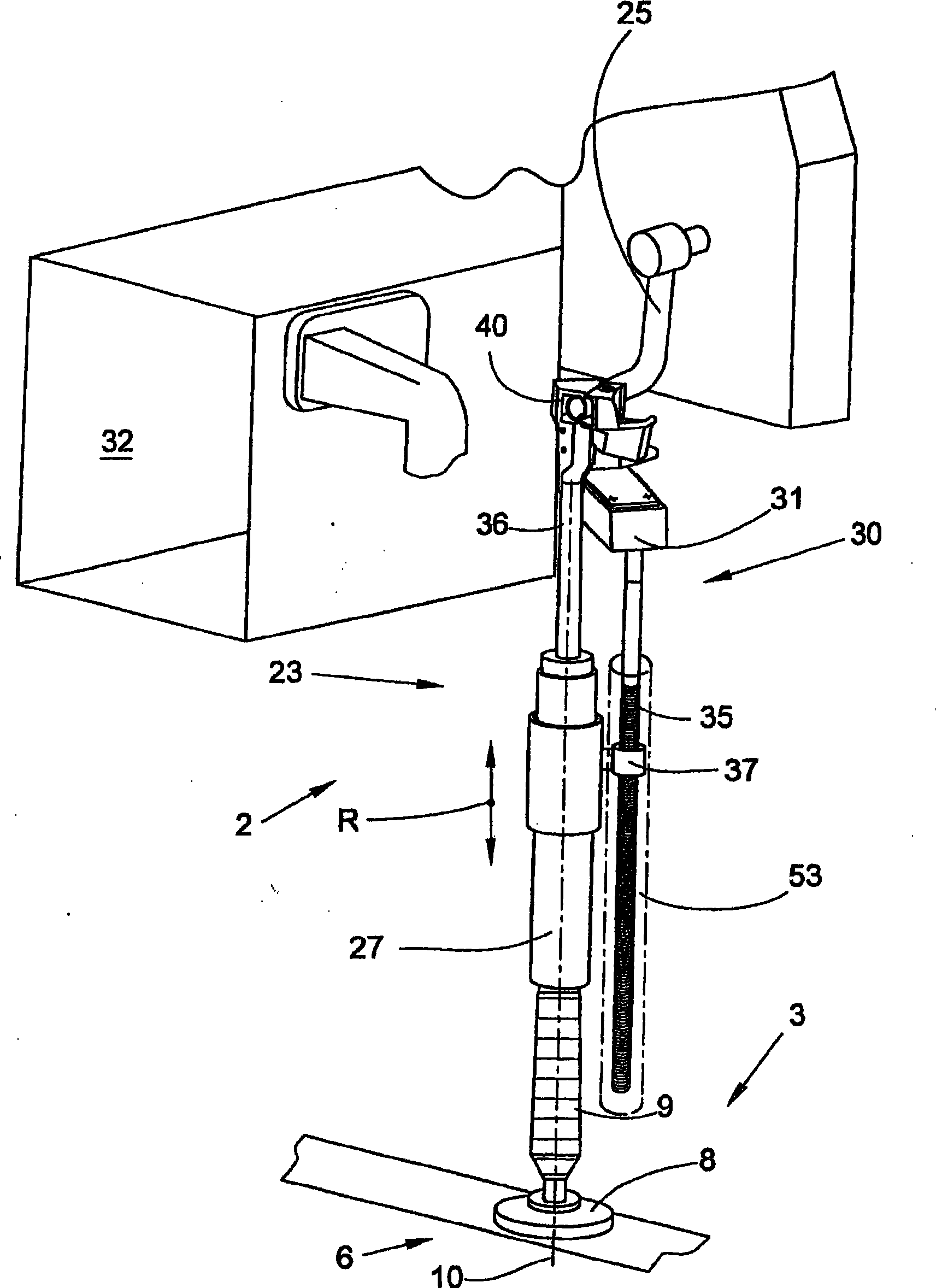

[0033] figure 1 A textile machine for producing cross-wound bobbins, which is referred to as automatic cross-winder 1 in this exemplary embodiment, is shown schematically in side view. This automatic crosswinder 1 has a plurality of stations or winding heads 2 of the same type between its end frames (not shown).

[0034] As known and thus not further described, at the spinning station 2 the spinning bobbin 9 produced on the (not shown) ring spinning machine and having only relatively little yarn material is Rewinding into large-capacity cross-wound bobbins 11, the cross-wound bobbins 11 are then conveyed by means of (not shown) automatically operated service units to a cross-wound bobbin conveying mechanism 21 arranged in the longitudinal direction of the machine and conveyed to A bobbin loading station (likewise not shown) arranged at the end of the machine or the like. In addition, if figure 1As shown, such an automatic cross-winder 1 preferably has a logistics system in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com