Down-hole mechanical movable-sieve jig

A moving sieve jig machine and mechanical technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of large space occupation, easy coal leakage, etc., and achieve reasonable layout, easy installation, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

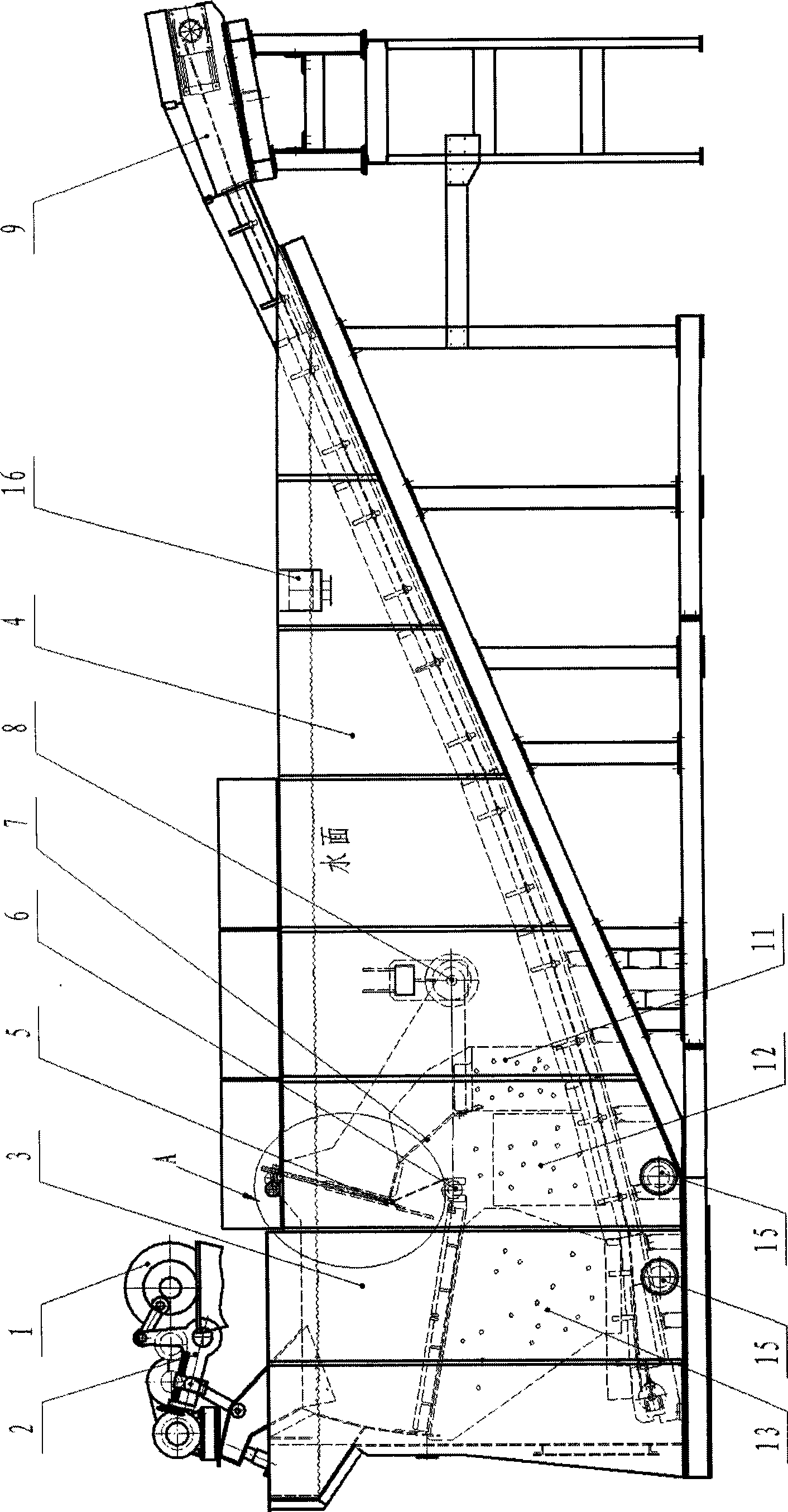

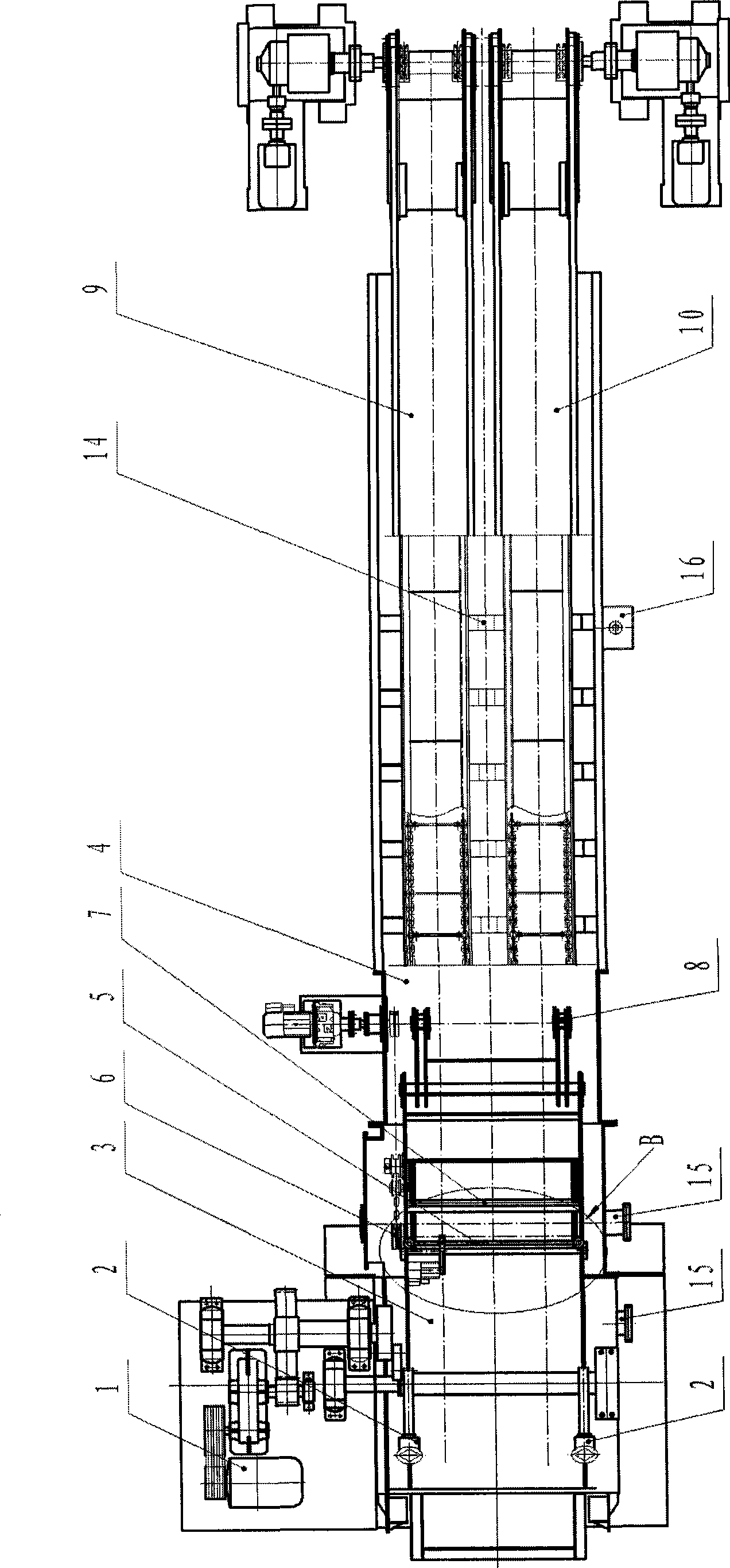

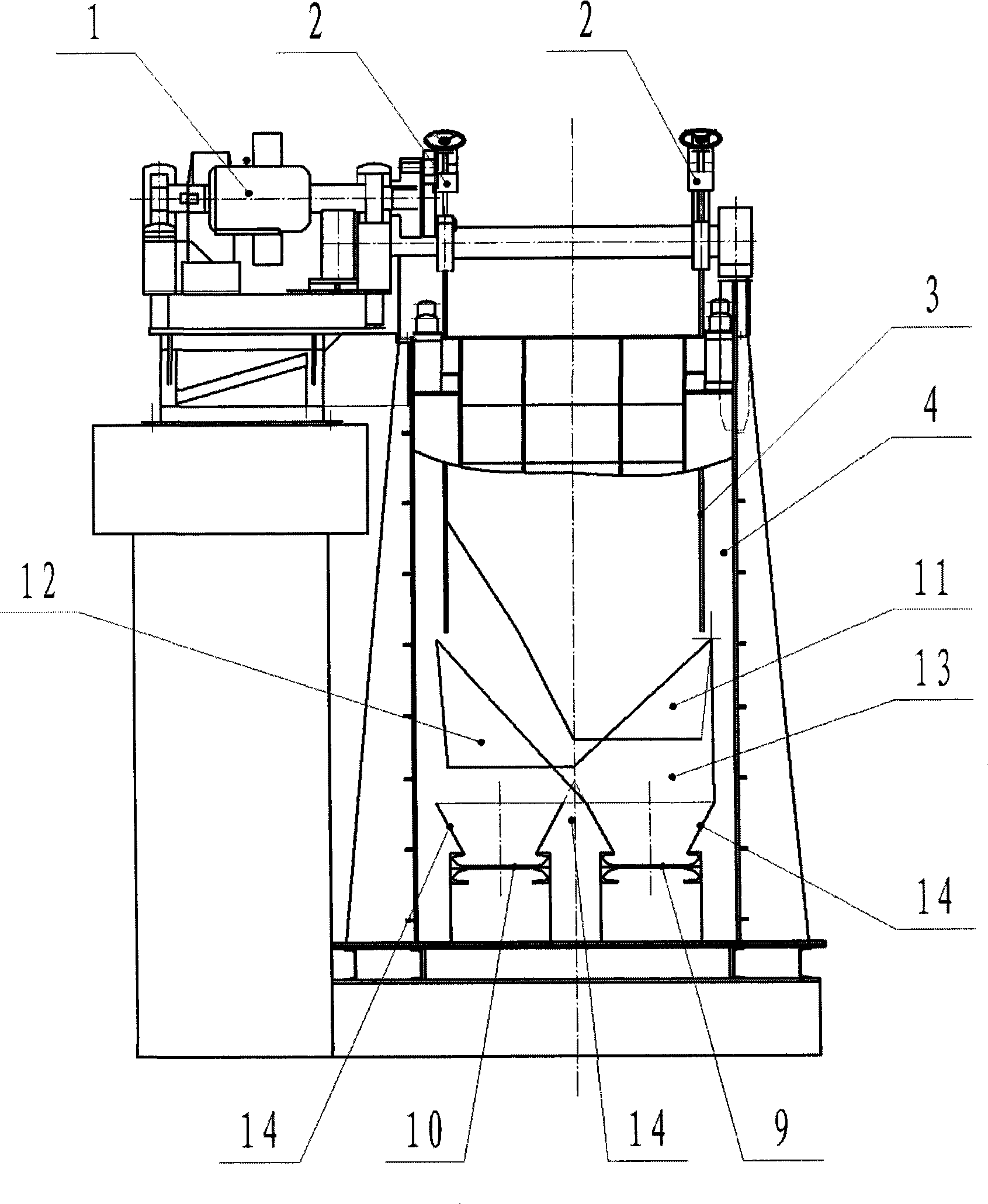

[0016] according to Figure 1-5 The specific structure of the present invention will be described in detail. The downhole mechanical dynamic screen jig includes a box body 4, a moving screen body 3 assembled on the box body 4 and driven by the main drive mechanism 1 and the crank linkage mechanism 2 and installed in the box body 4 through a fixed fulcrum 8, the installation Partition plate 7 and row gangue wheel 6 and material lifting mechanism in moving screen body 3. Wherein the structure of the main drive mechanism 1, the crank linkage mechanism 2 and the movable screen body 3 adopts the structure of the "downhole mechanical movable screen jig" designed by the inventor, and its specification and shape can be determined according to actual use requirements. The bottom of the box body 4 is provided with a flange mouth 15 that can be used for regular water change and desilting of the box body 4, and an overflow port 16 is provided on the upper part, and water is added to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com