Combined thermal transmission type micro roller drying device of tobacco

A technology of a small drum and drying device, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of processing shredded tobacco, inhomogeneous conduction and heat transfer, and inability of electric heating sheets to meet the uniform temperature field, and achieves a uniform temperature of the cylinder wall. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

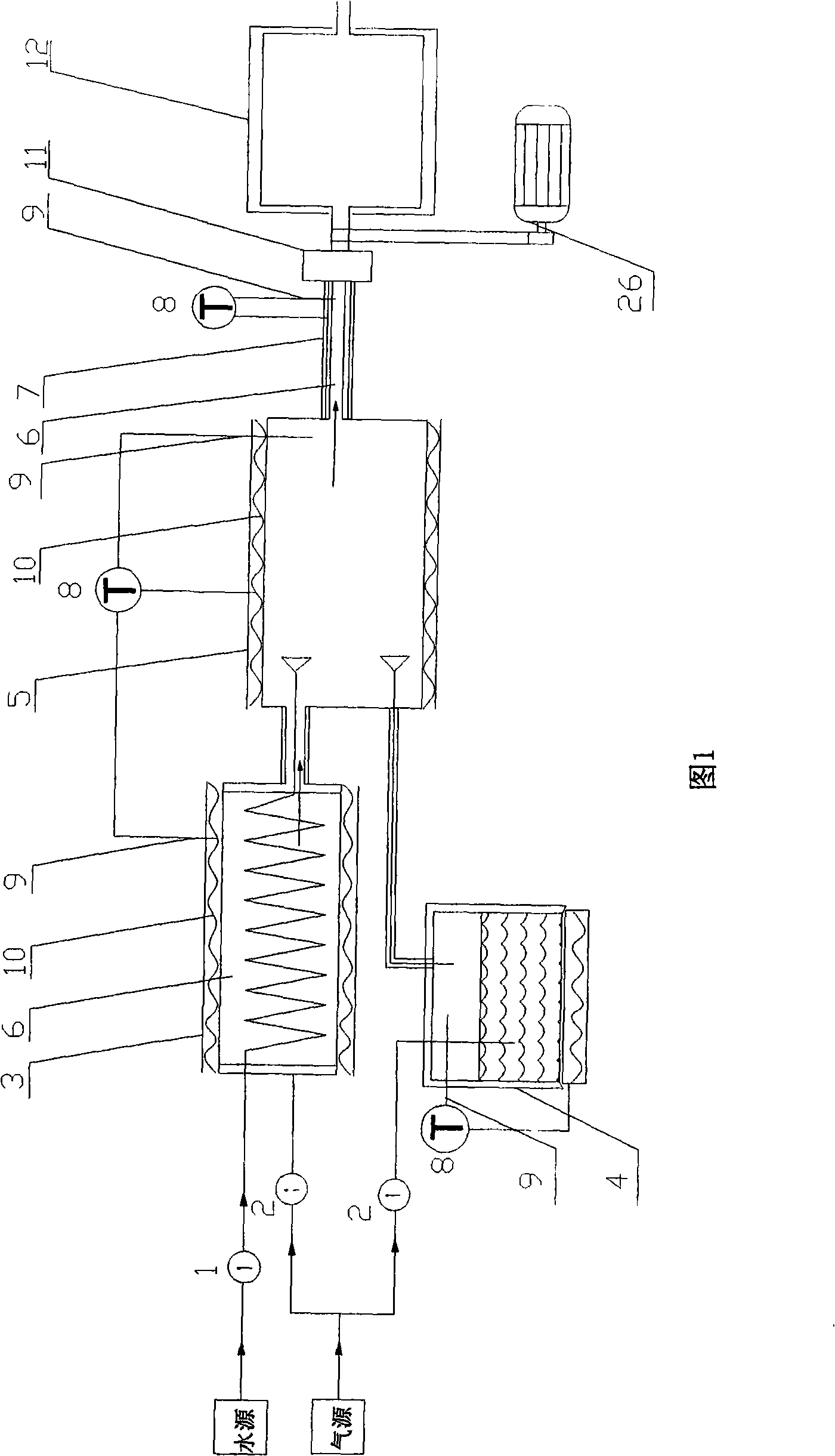

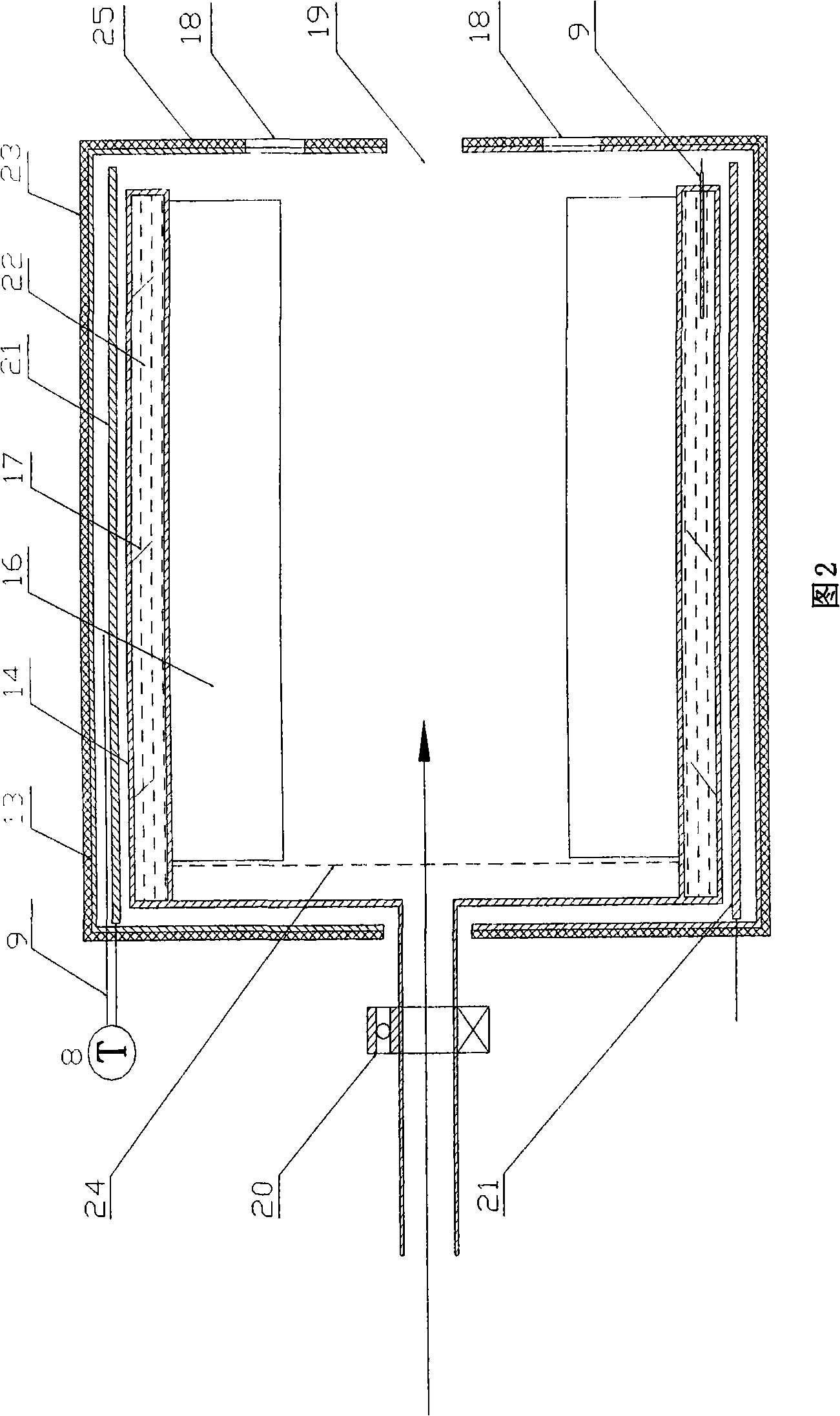

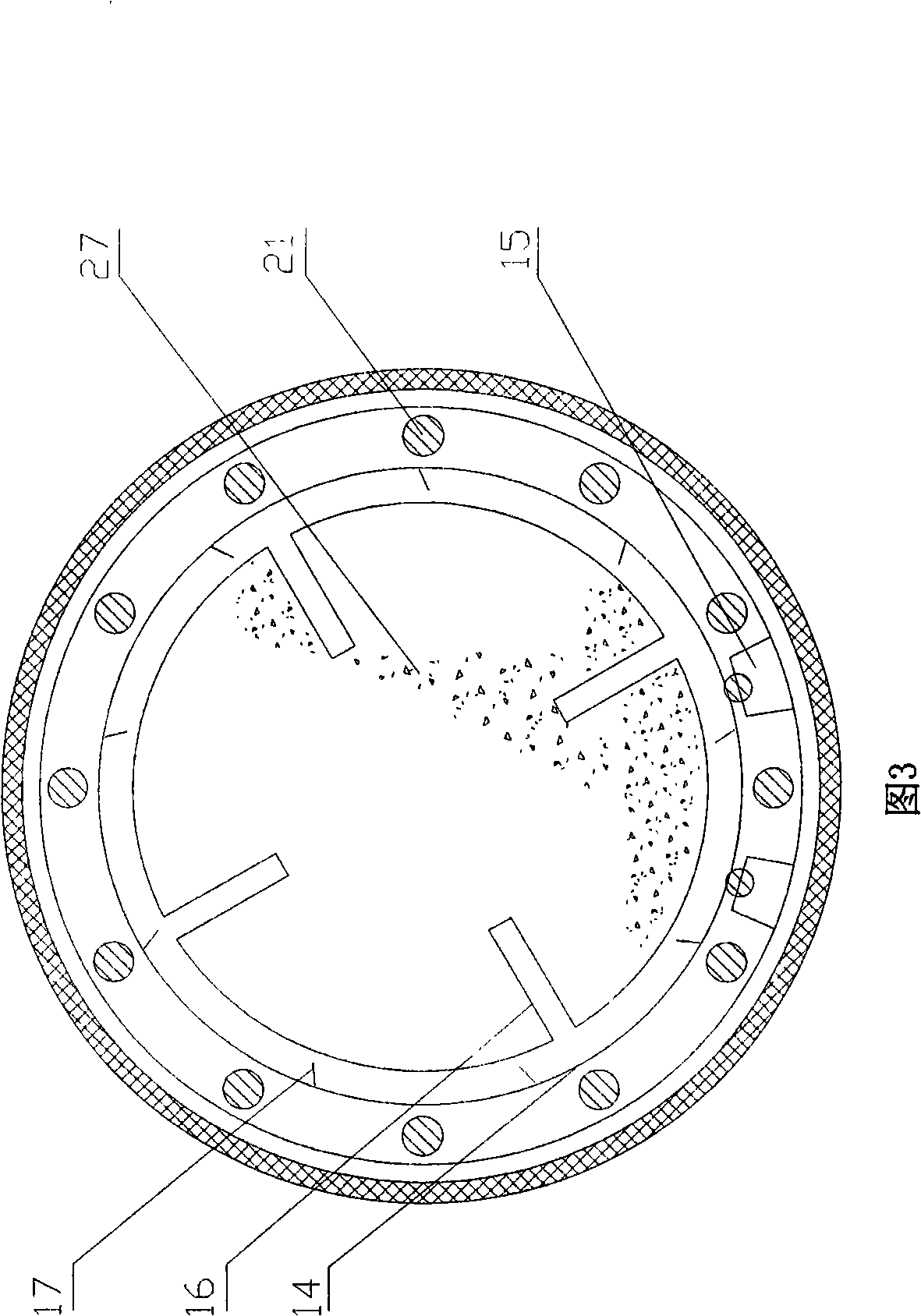

[0039] Embodiment 1, under the condition that the temperature of the dry gas medium is set to be above 90°C, it is possible to use dry gas sources (air, nitrogen, CO 2) leads out, through the flow meter 2 to control a certain flow of gas along the gas pipeline in the direction of the arrow into the preheater 3, through the preheater along the direction of the arrow into the mixer 5, the moisture content in the set dry gas medium is obtained by calculation , the output water volume of the metering water pump 1 is set, the output water enters the preheater 3 along the water pipe in the direction of the arrow for preheating, heating, and gasification, and enters the mixer 5 through the preheater in the direction of the arrow. The temperature controller 8 controls the heating capacity of the preheater 3 and the mixer 5. The temperature control here is set to be about 5°C to 10°C higher than the temperature of the dry gas medium, and the dry air with a certain moisture content forme...

Embodiment approach 2

[0040] Embodiment 2, under the condition that the temperature of the dry gas medium is set to be below 90°C, the dry gas source (air, nitrogen, CO 2 ), through the flow meter 2 to control a certain flow of gas, enter the gas channel of the preheater 3 along the gas pipeline in the direction of the arrow, and enter the gas channel of the preheater 3 along the direction of the arrow, and enter the mixer 5 through the preheater 3 in the direction of the arrow. The absolute dry gas flow rate of saturated humid air is obtained from the absolute dry gas source (air, nitrogen, CO 2 ) is drawn out, a certain flow rate of gas is controlled by the flowmeter and enters the saturated humid air generator 4 along the direction of the arrow, and the saturated humid air generator 4 is provided with a heating element 10, an intelligent temperature controller 8 and an insulation layer, and through the intelligent temperature controller 8 The temperature of the saturated humid air generator 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com