Electric mop pool and mop

A mop and electric technology, applied in the field of sanitary ware, can solve the problems of poor decontamination ability and adsorption capacity, not easy to wash and wring out, easy to mold, etc. The effect of high dryness, not easy to be affected by moisture or leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

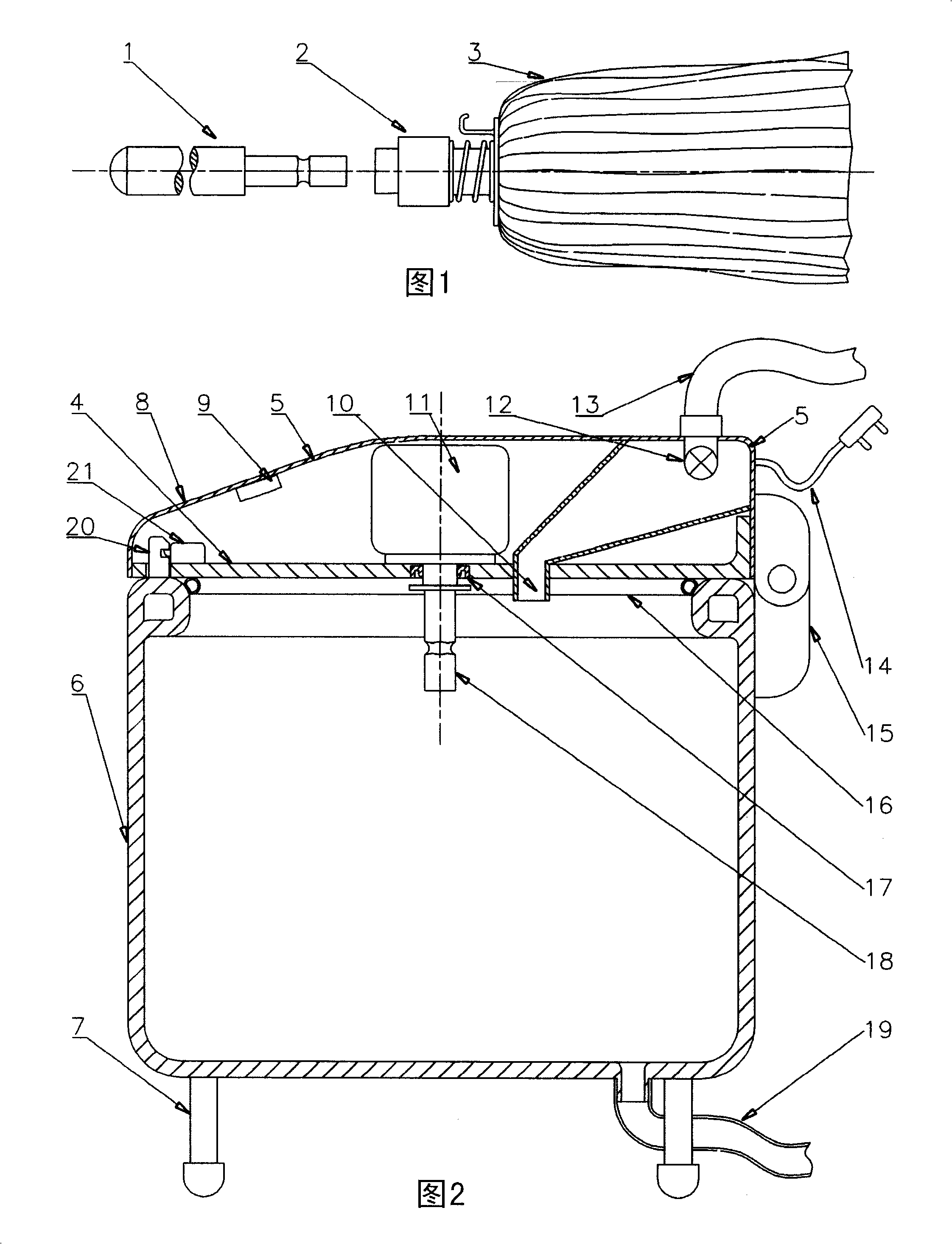

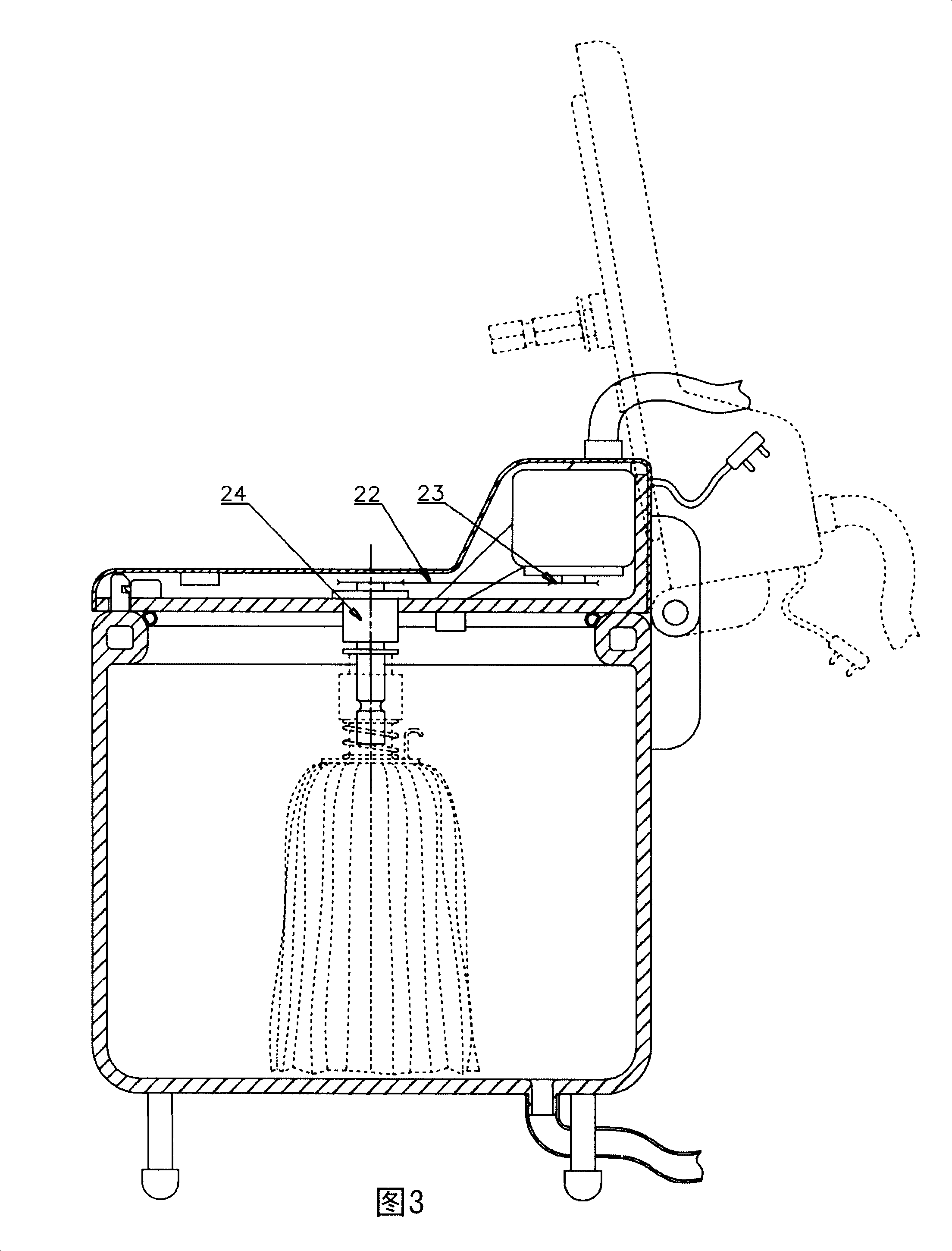

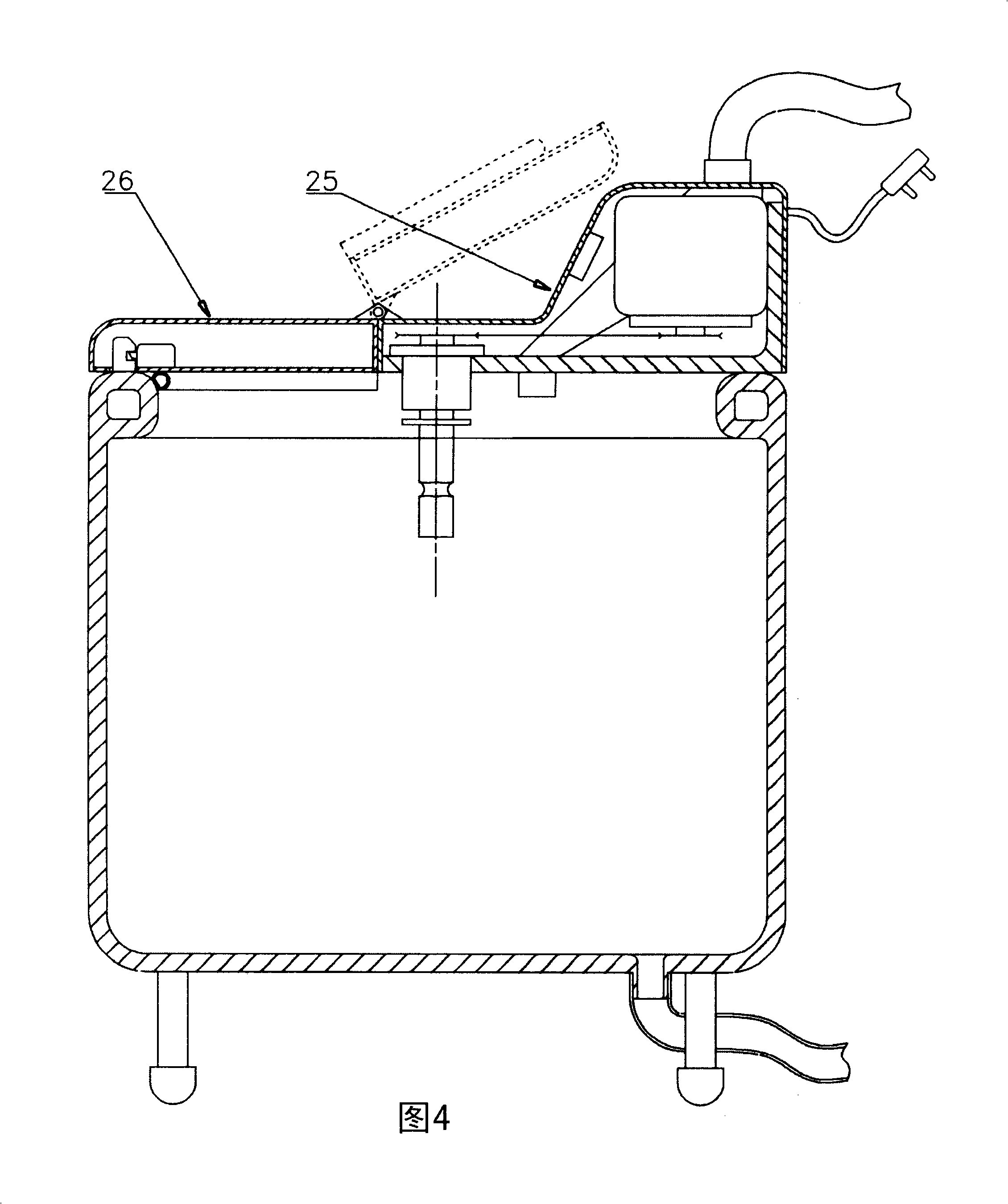

[0039] A mop as shown in FIG. 1 is composed of a mop handle 1 , a connector 2 and a cloth strip 3 . The cloth strip 3 is fixed on the connecting head 2 to form a mop head, and the mop head is equipped with a mop handle 1 to form a mop, which can carry out mopping work. The mop handle 1 and the connecting head 2 can be disassembled, and the effect of the mop handle 1 is to hold and use the mop for the user. For ease of use, the mop handle can also be made telescopically adjustable in length. The lower end of the mop handle is a shaft or a hole structure matched with the connector, the diameter of the connection part connected between the mop handle 1 and the connector 2, the cross-sectional shape and the groove 27 arranged on the connection part, the steel ball 35 with a spring, An annular groove 34 or a ball retainer 30 may coincide with the power shaft 18 . The upper end of the connector 2 is a hole or shaft structure (Fig. 6, Fig. 8, Fig. 10, Fig. 12) that can be connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com