Milky perfume and preparation method thereof

A preparation method and perfume technology, which are applied to the formulation of perfume preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve the problems of customers not being able to smell the fragrance in time, inconvenient for consumers to use immediately, difficult to prepare fresh and elegant, etc. The effect of good fragrance persistence, good and stable performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, take raw material by following proportioning ratio:

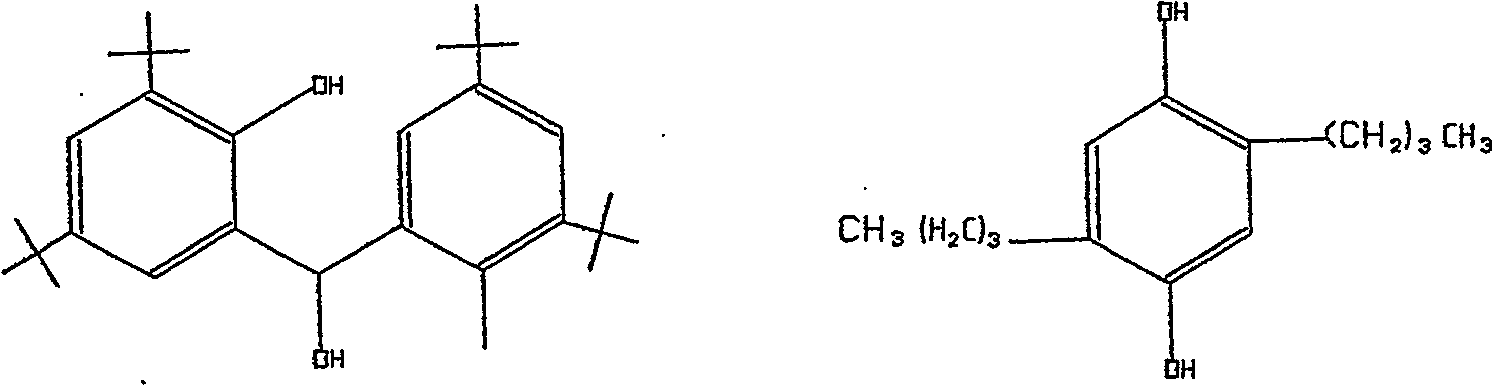

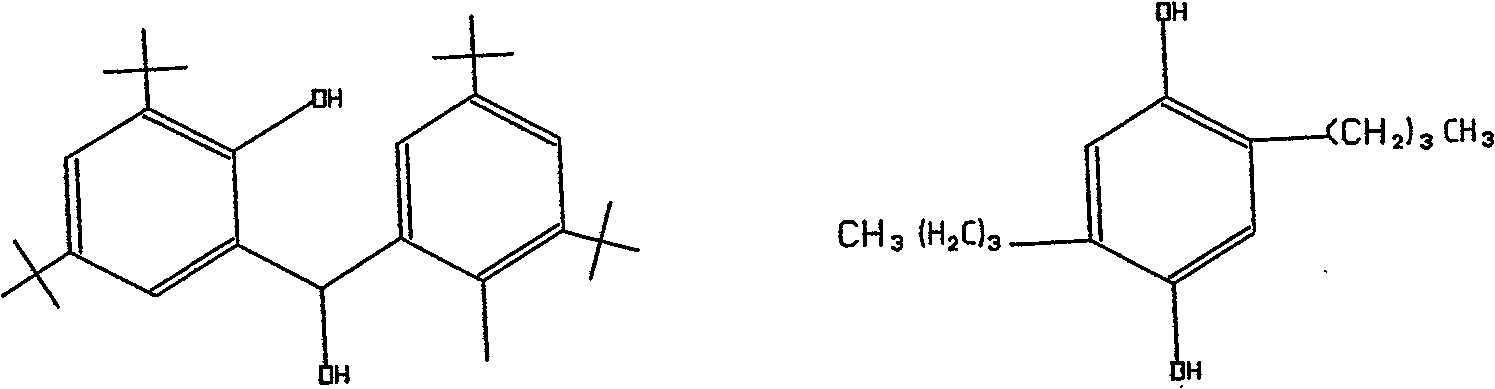

[0028] Essence 17g, Carbomer (Carbomer 940) 0.8g, distilled water 53.1g, ethanol 20g, isopropyl myristate (1PM) 1g, essence solubilizer, hydrogenated castor oil (PEG-40) 5g, humectant propylene glycol 1g, Anti-ultraviolet agent (Eslalol 577) 2g, antioxidant, tetrabutylethylene bisphenol (NOA) 0.08g, toner 0.02g, distilled water is a reference value in the formula, and adjusting the distilled water consumption can make the whole formula total amount be 100g or the sum of mass percentages is 100%.

[0029] Production method: (1) Essence emulsification and aging: Take the weighed essence, add essence solubilizer and fragrance fixative, add half the amount of ethanol (10g), air bubble for 30 minutes, and store in a frozen state of minus 5 degrees for a week. Then thaw at room temperature, filter, and take the filtrate. (2) Production of perfume milk base: put Carbomer 940 in about half of the distilled wa...

Embodiment 2

[0032] Embodiment 2, take raw material by following proportioning ratio:

[0033] Essence 25g, Carbomer (Carbomer 940) 1.2g, distilled water 40.76g, ethanol 20g, deodorant isooctyl palmitate (Cegesoft c 24 ) 2g, flavor solubilizer Eumulgin HPS 5g, humectant glycerol 1g, anti-ultraviolet agent (Eslalol 577) 5g, antioxidant 2,5-dibutylhydroquinone 0.01g, chelating agent EDTA0.02g, color tone Dose 0.01g.

[0034] The amount of distilled water in the formula is a reference value, and the amount of distilled water can be adjusted so that the total amount of the entire formula is 100g or the sum of the mass percentages is 100%.

[0035] Production method: (1) Essence emulsification and aging: Take the weighed essence, add essence solubilizer and fixative, add half the amount of ethanol (10g), air bubble for several minutes, and let it stand in a frozen state (around 0°C) Aging for one week, filtering, and taking the filtrate. (2) Production of perfume milk base: Put Carbomer 940 in...

Embodiment 3

[0038] Embodiment 3, take raw material by following proportioning ratio:

[0039] Essence 12g, Carbomer (Carbomer 940) 0.2g, distilled water 59.24, ethanol 20g, deodorant, caprylic capric triglyceride (GTCC) 0.5g, essence solubilizer, hydrogenated castor oil (PEG-40) 2.5g, 0.5 g of propylene glycol as a humectant, 5 g of an antiultraviolet agent (Eslalol 577), 0.05 g of an antioxidant 2,5-dibutylhydroquinone, and 0.01 g of a toner.

[0040] The amount of distilled water in the formula is a reference value, and the amount of distilled water can be adjusted so that the total amount of the whole formula is 100g or the sum of mass percentages is 100%.

[0041] Production method: (1) Essence emulsification and aging: Take the weighed essence, add essence solubilizer and fixative, add half the amount of ethanol (10g), air bubble for several minutes, and let it stand in a frozen state (around 0°C) Aging for one week, filtering, and taking the filtrate. (2) Production of perfume mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com