Self-centering four-jaw independent chuck

A four-jaw chuck, self-centering technology, applied in the direction of the chuck, can solve the problems of small adjustment range, inconvenient operation, high cost, and achieve the effect of improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation methods provided according to the present invention are described in detail below in conjunction with the preferred embodiments.

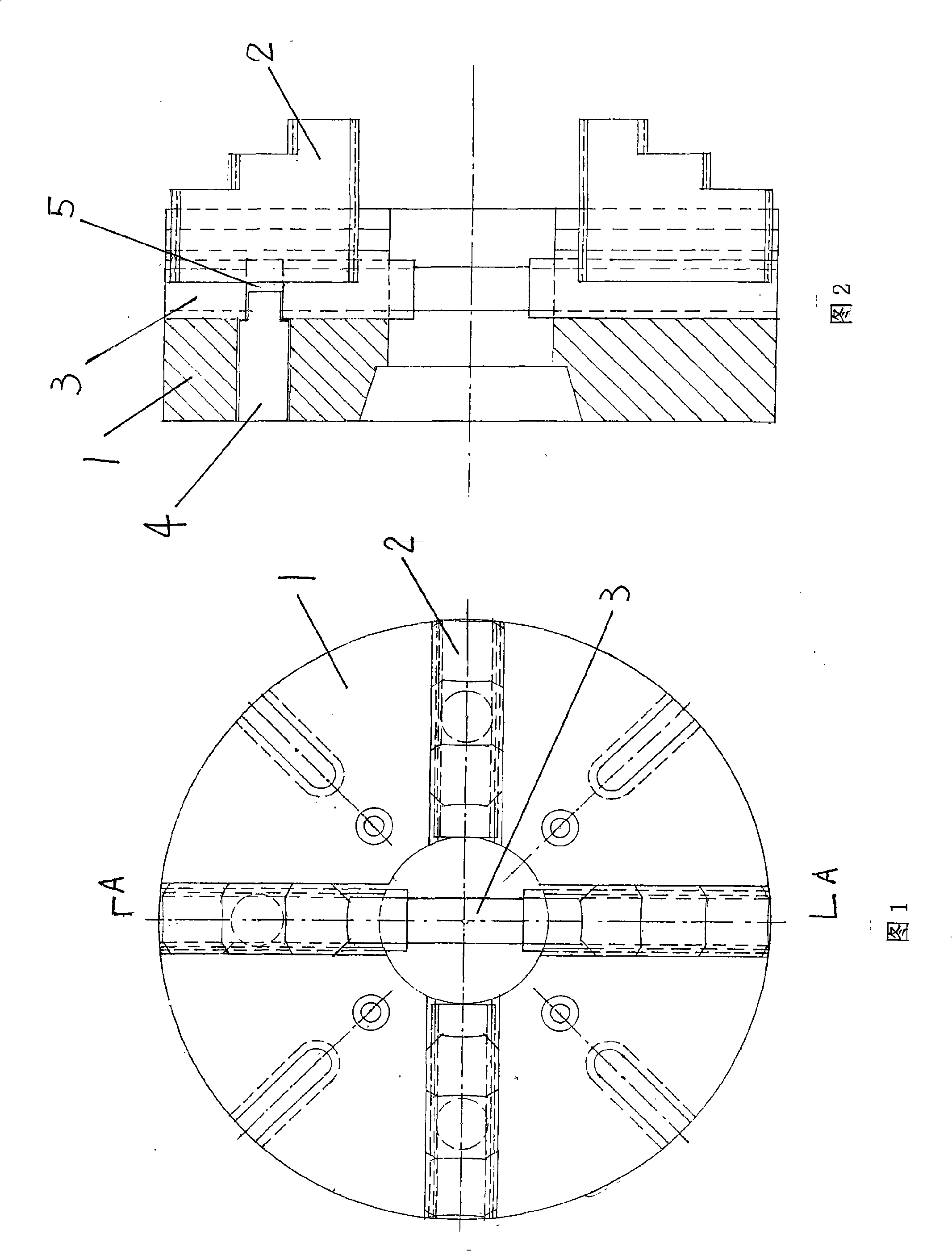

[0010] See the accompanying drawings for details, a self-centering four-jaw chuck, including a disc body 1, a set of four jaws 2 and a lead screw 3 that engages with them one by one, and the front end of the positioning shaft 4 on the disc body Insert the key block into the annular limit groove of the lead screw, keep two of the four lead screws in the original state, and set the opposite two lead screws as a whole single lead screw, the single lead screw The threads at both ends are respectively engaged with the threads of the corresponding claws. The single lead screw is inserted through a positioning shaft that is pinned to the disc body.

[0011] Working principle: When working, among the four screw screws, for example, two screw screws in the horizontal direction are made into a single screw screw. Threads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com