Spinning method for multicolor yarn

A technology of yarn and color, applied in the direction of yarn, textiles and papermaking, can solve the problems of uniform spacing, single style, unsatisfactory clothing, etc., to achieve the effect of unique style, beautify life, and enhance randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

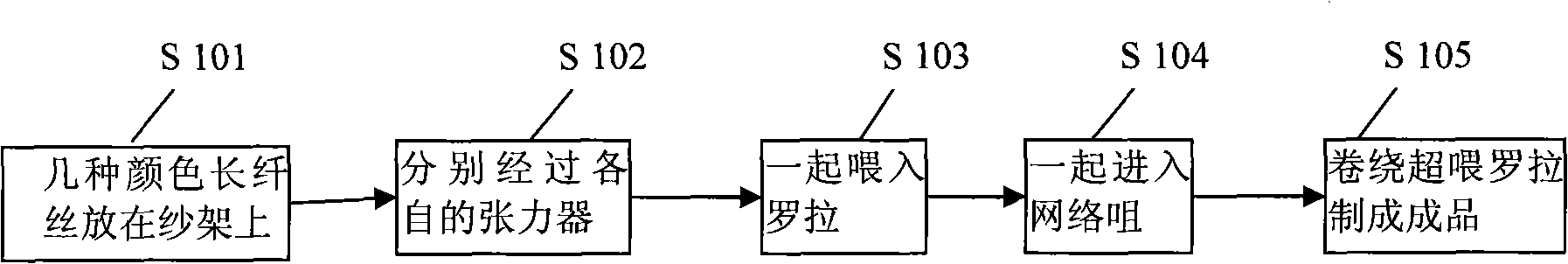

[0015] figure 1 A conventional method of spinning multicolored yarns is shown, the method comprising a number of steps as follows:

[0016] Step S101, select some (one or several) from several colored long filaments that need to be mixed, and first place each selected filament on the creel separately;

[0017] Step S102, making filaments of various colors pass through respective tensioners;

[0018] Step S103, making the filaments of various colors through the tensioner enter the roller together;

[0019] Step S104, the filaments of various colors enter the network nozzle together, and the high-pressure compressed air passes through the network nozzle to form an impact airflow to impact the passing yarn, and by means of mutual friction between fibers and yarn molecules The internal stress of the multi-color mixed air-covered network yarn with uniform color mixing is formed;

[0020] In step S105, the multi-color filaments that have been networked are passed through winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com