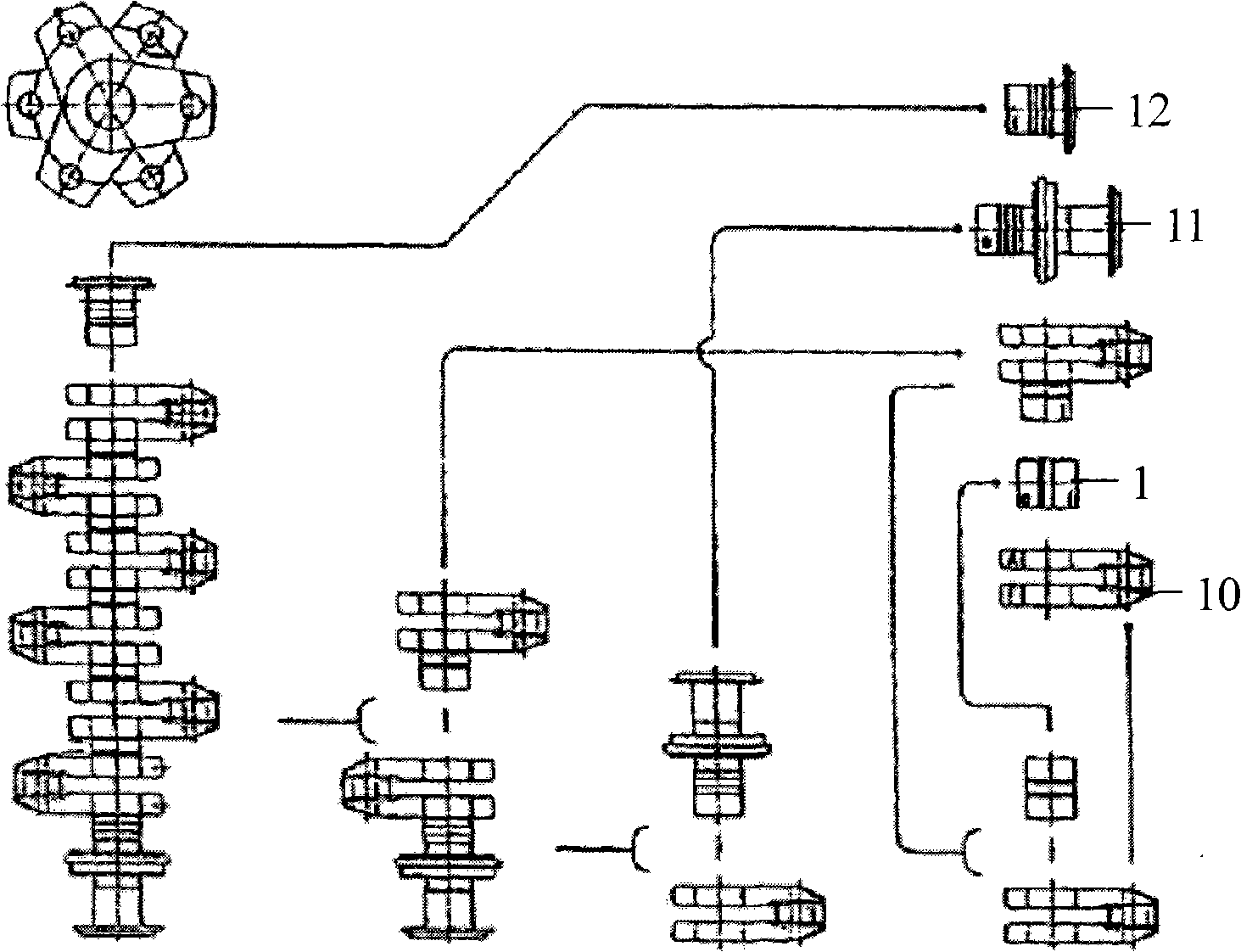

Reconfiguration method in shrinkingon process of crankshaft for studying ship and measure for preventing deformation

A technology of structural deformation and process structure, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as reducing processing efficiency, increasing the difficulty and difficulty of machining, reducing development costs and eliminating structural deformation. , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

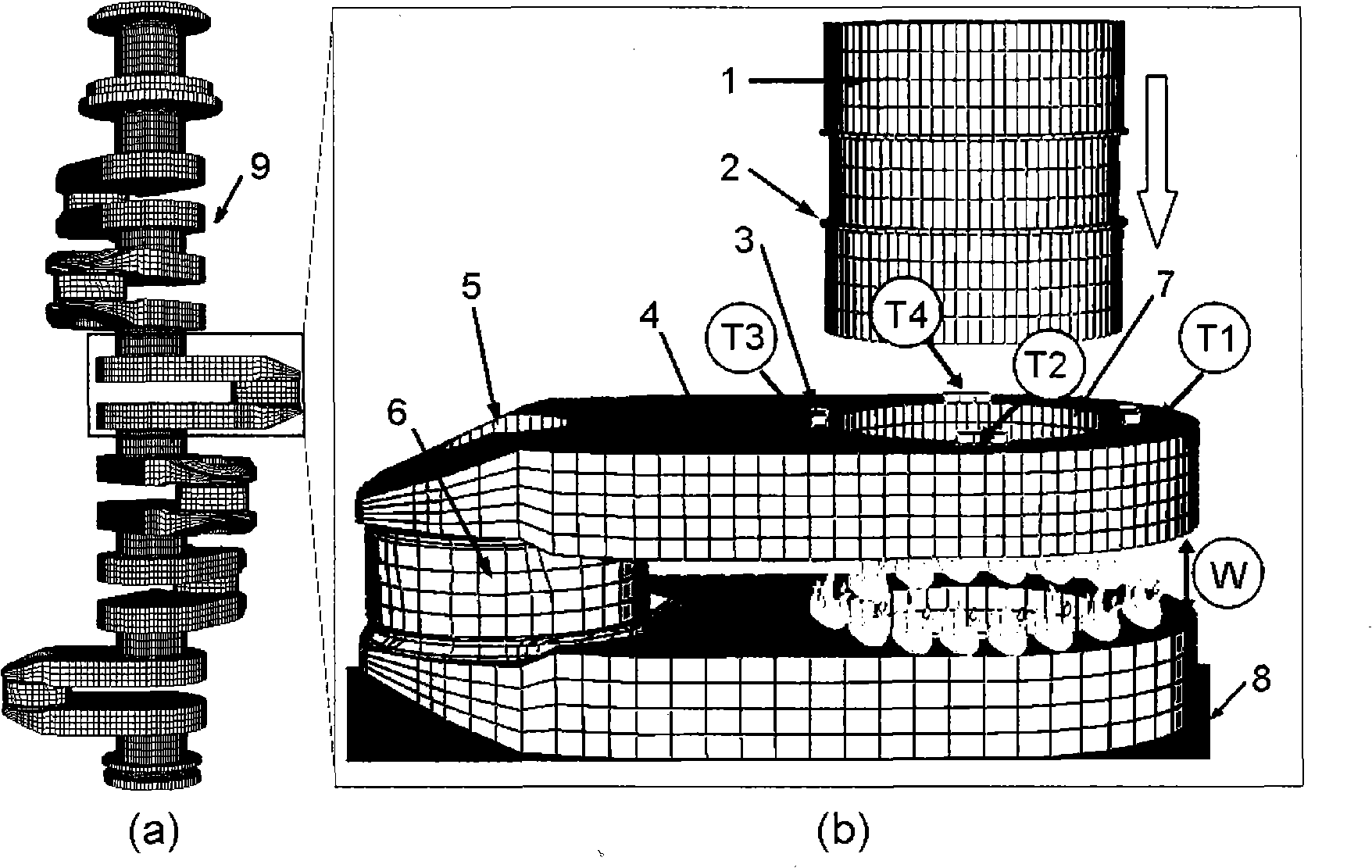

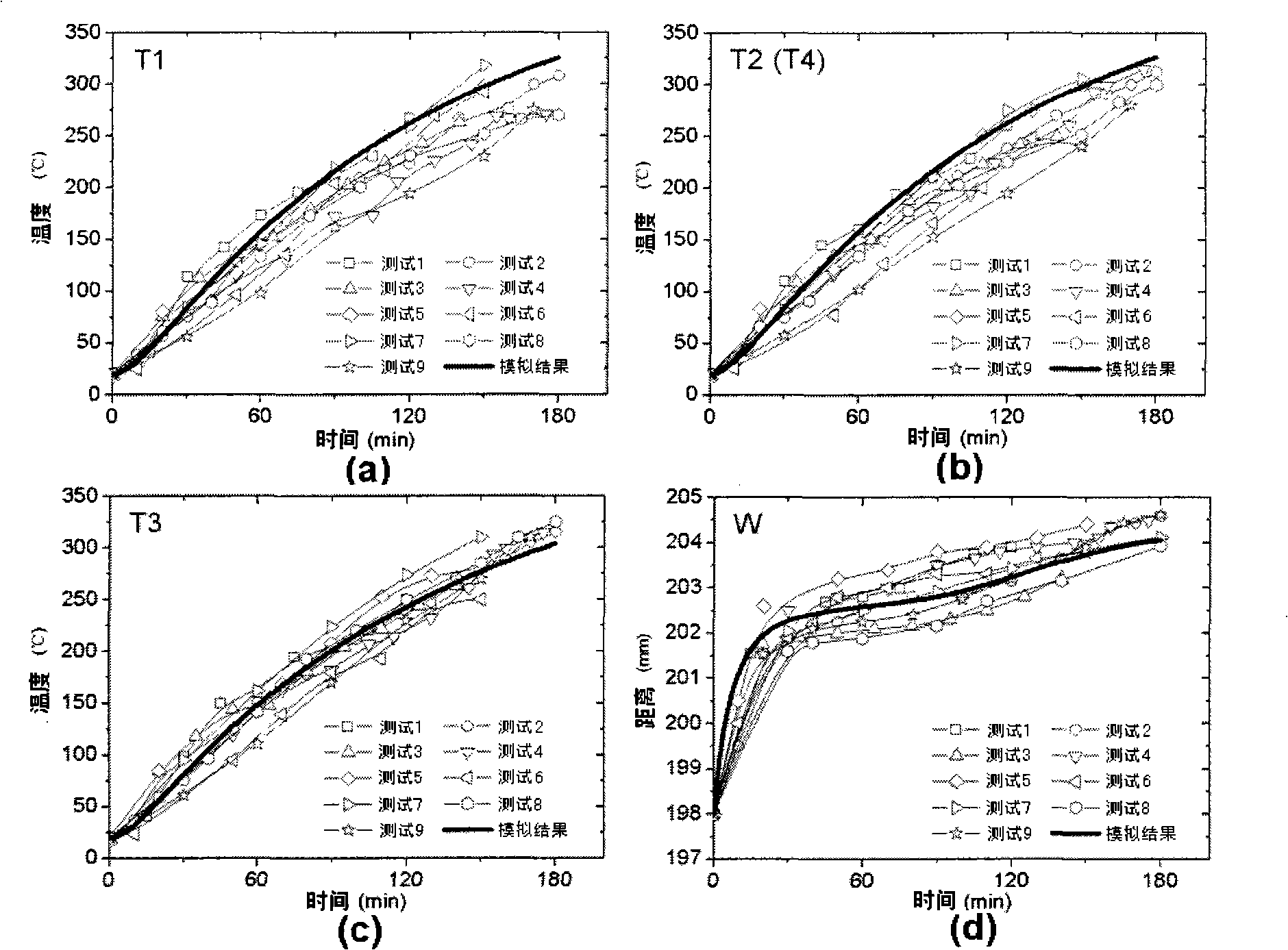

Method used

Image

Examples

Embodiment

[0046] The design formula of the interference δ of the red sleeve is:

[0047] δ = 1 2 [ b ( c 2 - a 2 ) ( c 2 - b 2 ) ( b 2 - a 2 ) · Torque π ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com