Cartridge with high safety and low amount of residual liquid of pen type insulin syringe

A pen core and piston technology, applied in the field of medical devices, can solve the problem of excessive insulin, achieve high input-output ratio, accurate measurement and display, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

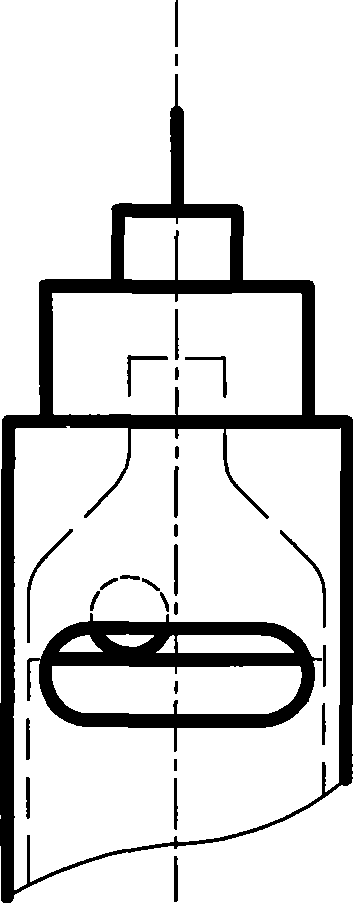

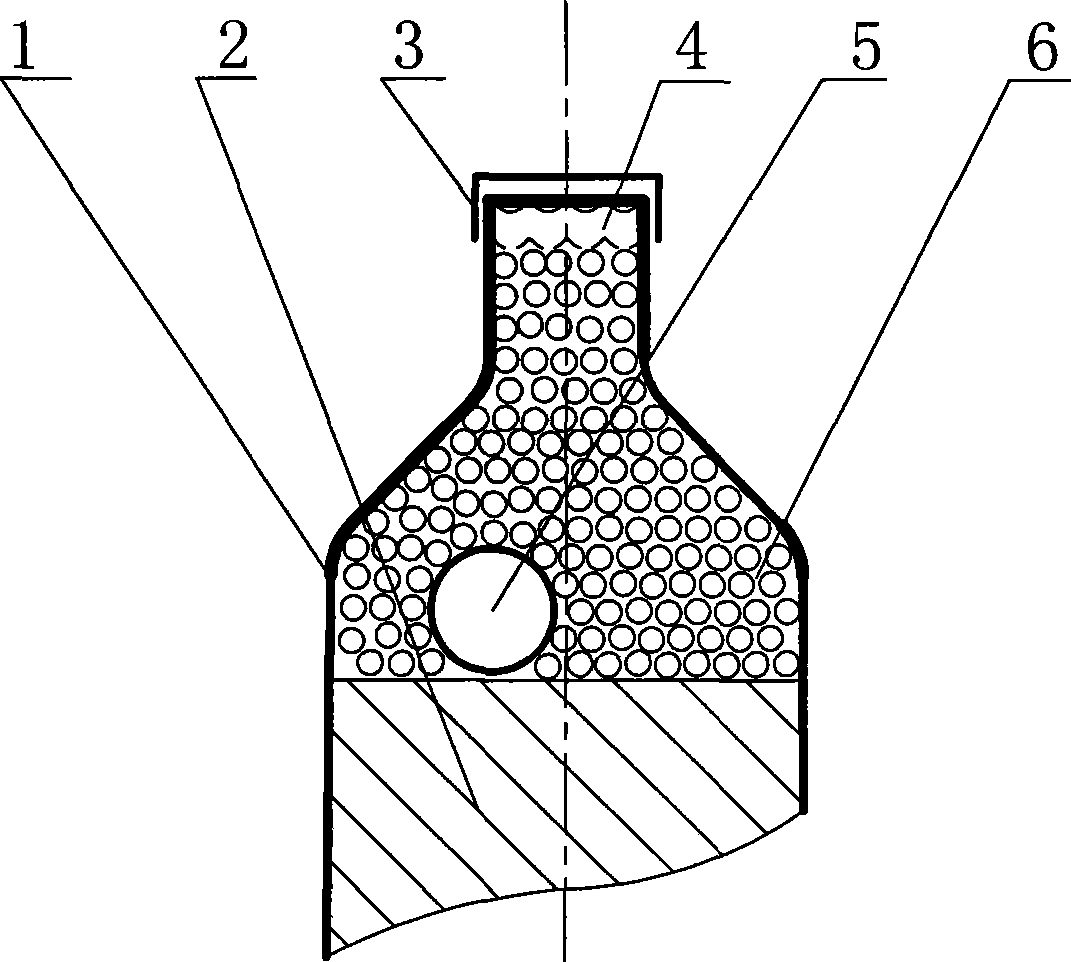

[0038] exist figure 2 In Zhongyuan’s insulin refill, in the remaining space formed by the refill bottle 1, bottle cap 3 and the original piston 2 at the end of the injection stroke, there are insulin residue 4 and an original glass ball with a diameter of 2.5 mm In the case of 5, it is filled with granular solid substances 6, and the alternative substances can be spherical substances with stable properties such as plastics, glass, and ceramics with a diameter less than 2.5 mm. For example, 10 glass balls with a diameter of 2.5 mm can replace about 6 units of liquid medicine, and 30 glass balls with a diameter of 1.5 mm have certain effects. When the specific gravity of the granular solid material is plastic, it mainly plays the role of replacing the insulin residual liquid when it is used up.

Embodiment 2

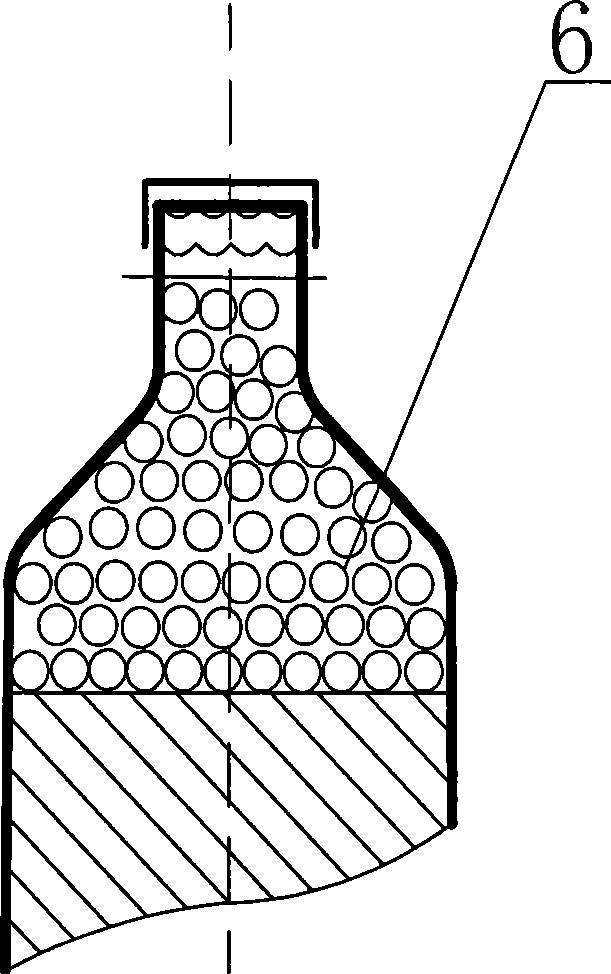

[0040] exist image 3 Among them, because substitutes use materials with high specific gravity such as glass and pottery, and can fully replace the original glass balls that play a role in mixing, the glass balls are therefore cancelled. In this example, the substitute is selected with low price and good performance glass microspheres. For example, 400 glass microspheres with a diameter of 0.8-1 mm or 600 glass beads with a diameter of 0.6-0.8 mm can replace about 12 units of drug solution.

Embodiment 3

[0042] exist Figure 4 In order to further reduce the amount of residual liquid, a new substitute disc 7 is added, and it is connected with the piston as a whole, so as to reduce the remaining space occupied by the liquid medicine and the glass microspheres. By adjusting the thickness of the wafer and the glass beads, the remaining space occupied by the liquid medicine and the glass beads can be controlled, and the way the push rod stroke ends or the end of the touch of the glass beads can also be controlled. In order to make the remaining amount correspond to the indication on the syringe and make it clearer, the disc can be made of eye-catching white or green. Under the limited conditions of the original pen-type insulin syringe, after experiments, the distance between the disc and the shoulder of the bottle is about 1 mm, the thickness of the disc is about 2 mm, and the diameter of the glass beads is less than 1 mm, so the effect is relatively good.

[0043] Experiment pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com