Processing method of upper shaft used for steering apparatus

A processing method and technology for a steering device, which are applied in the steering column, steering control mounted on a vehicle, transportation and packaging, etc., can solve the problems of reduced processing precision and processing speed, complex device structure, and large material consumption. The effect of improving machining precision, saving material and increasing machining speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

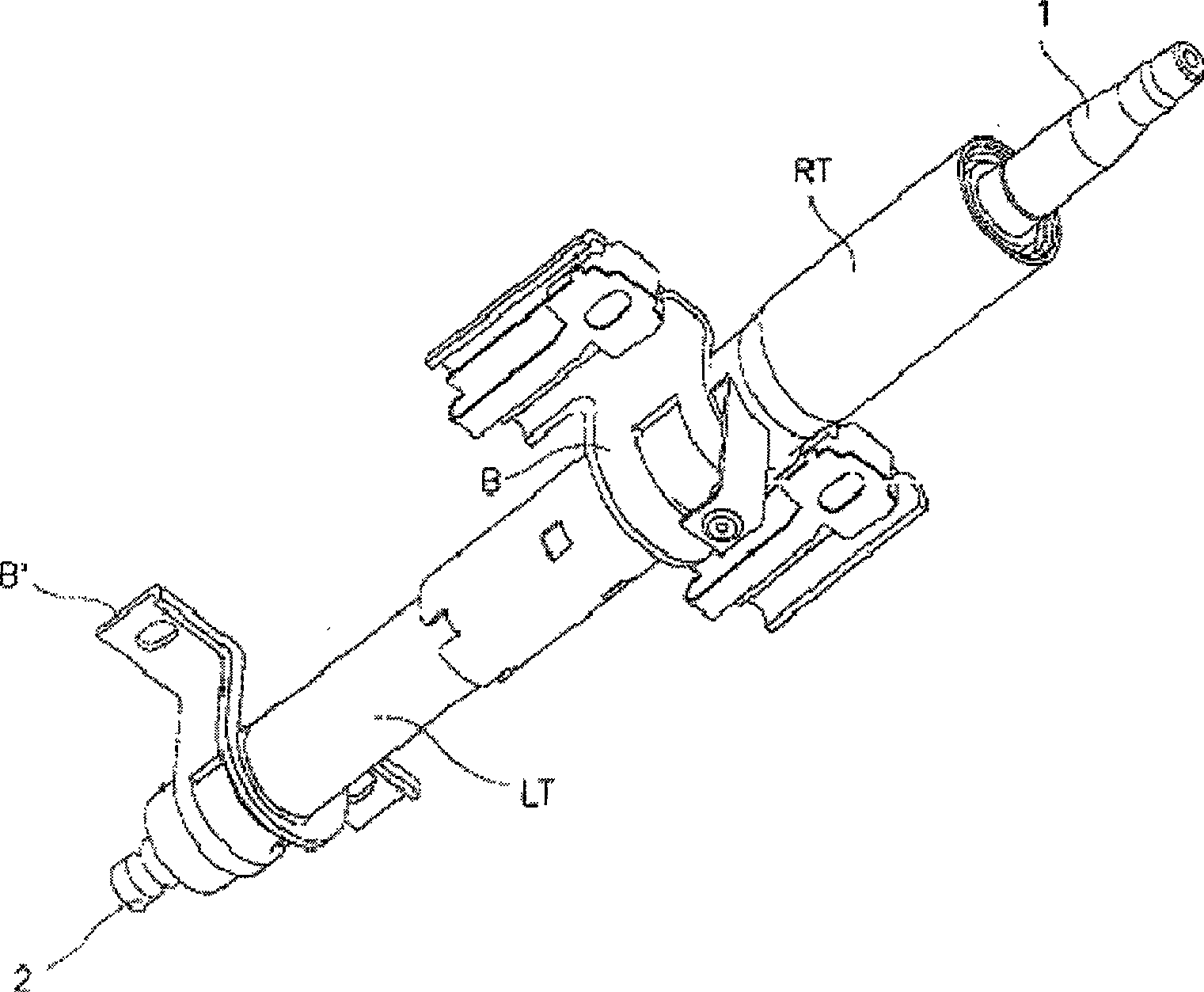

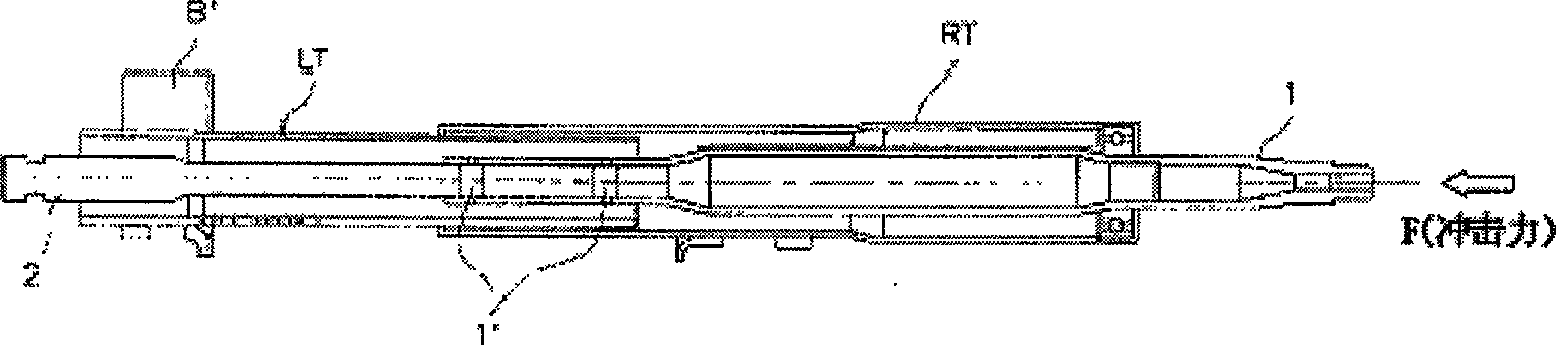

[0024] The method for machining the upper end shaft of the steering device in the embodiment of the present invention will be described below.

[0025] refer to Figure 4g , the upper end shaft 30 includes: a first joint part 31 combined with a hexagonal cross-sectional shape of the steering wheel; a second joint part 33 formed with an inner diameter keyway (spline) and combined with the lower end shaft; formed on the first and second joint parts 31 , 33 between the tapered portion 32.

[0026] Figure 5 to Figure 7 It is a schematic diagram of a preferred processing device for realizing the processing method in the present invention, Figure 5a to Figure 5f respectively Figure 7 Cross-sectional views of A-A line, B-B line, C-C line, D-D line, E-E line and F-F line.

[0027] The processing method in the embodiment of the present invention is as Figure 7 , the gradually deformed deformation shafts (30b-30f) are sequentially moved and inserted on the fixed block 10 for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com