Output machine for converting buoyancy into rotating force

A technology of rotating power and output machine, applied in the direction of engine components, machines/engines, hydroelectric power generation, etc., can solve the problems of energy consumption and pollution, and achieve the effect of solving the problem of environmental pollution and solving the lack of social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

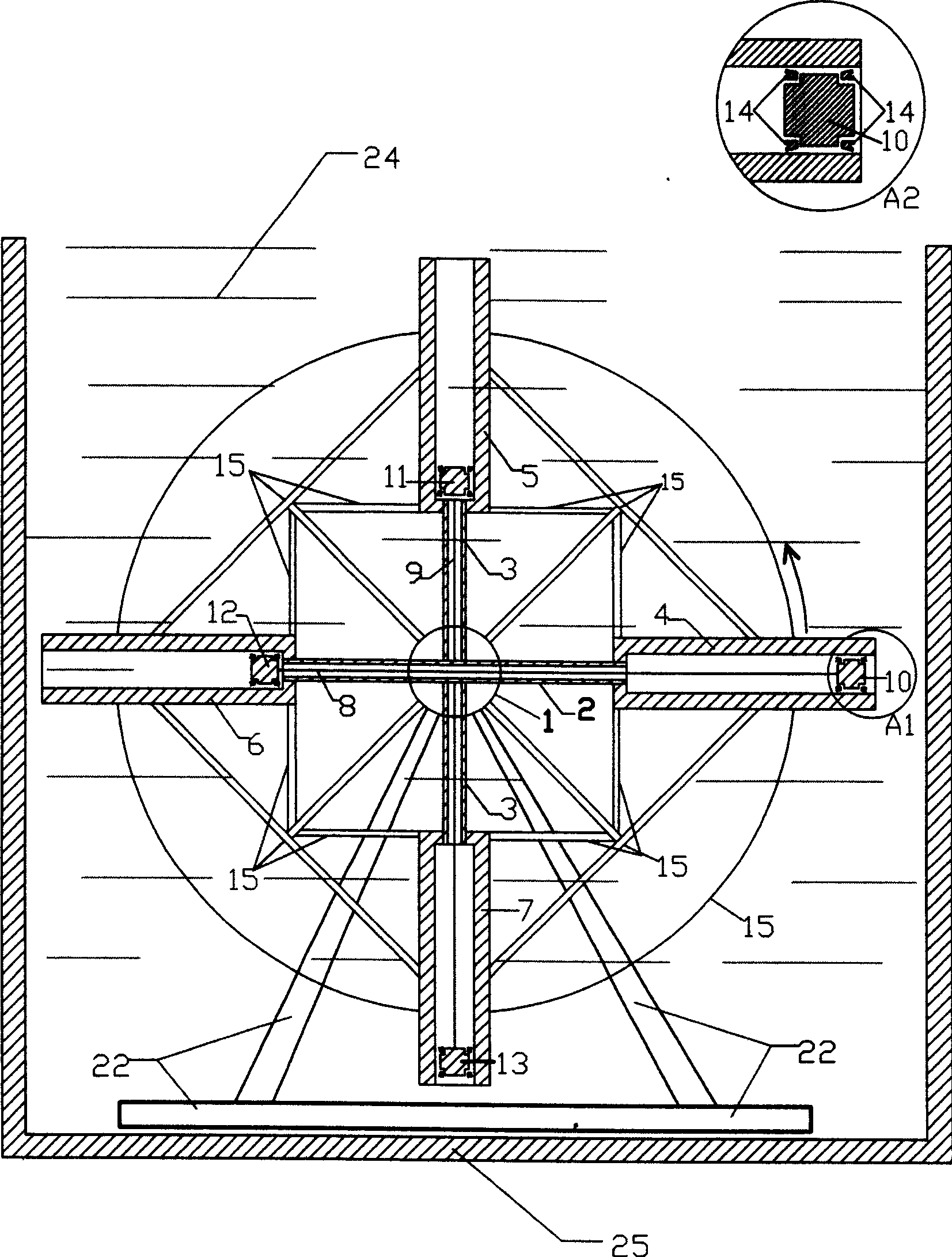

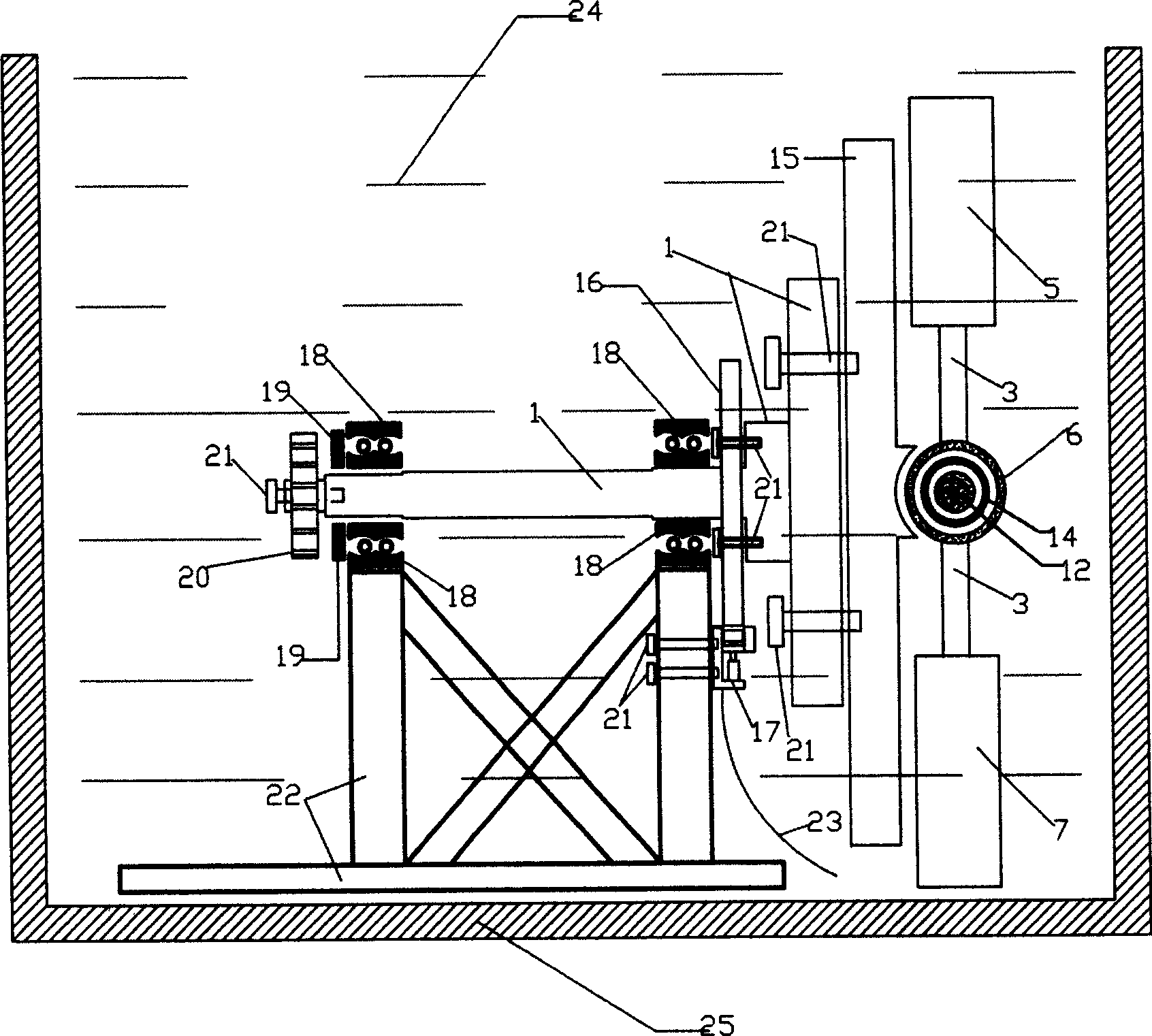

[0010] exist figure 1 Among them, many liquids (24) are housed in the container pool (25), the main parts are soaked in the liquid (24), and the support seat (22) is installed in the container pool (25), and the main shaft is installed on the support seat (22). (1), a pallet (15) is installed on the main shaft (1), the axis point of the main shaft (1) is aligned with the center point of the pallet (15), cylinder A (4) and cylinder B are installed on the pallet (5), Cylinder C (6), Cylinder D (7), each cylinder is evenly distributed on the periphery of the tray (15), and the symmetrical cylinder A (4) and cylinder C (6) use a through pipe A (2) is sealed and connected to form a closed and connected cavity. The symmetrical cylinder B (5) and cylinder D (7) are sealed and connected with the through pipe B (3) to form a closed and connected cavity. Body A (4), cylinder B (5), cylinder C (6), and cylinder D (7) are equipped with piston A (10), piston B (11), piston C (12), and pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com