LED bulb welding machine

A technology of LED light bulbs and welding machines, which is applied in connection, electrical components, circuits, etc., and can solve problems such as the easy burning of solenoid valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

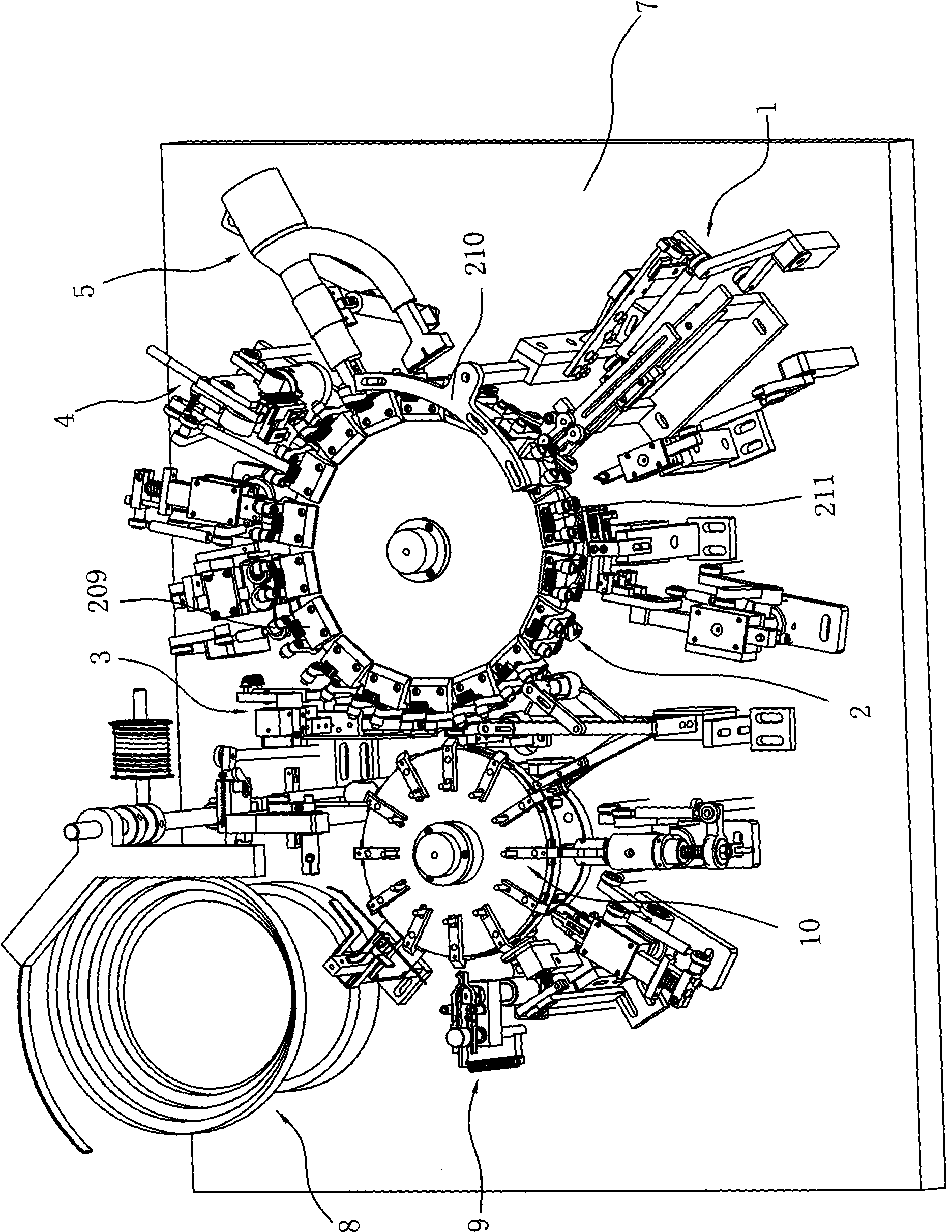

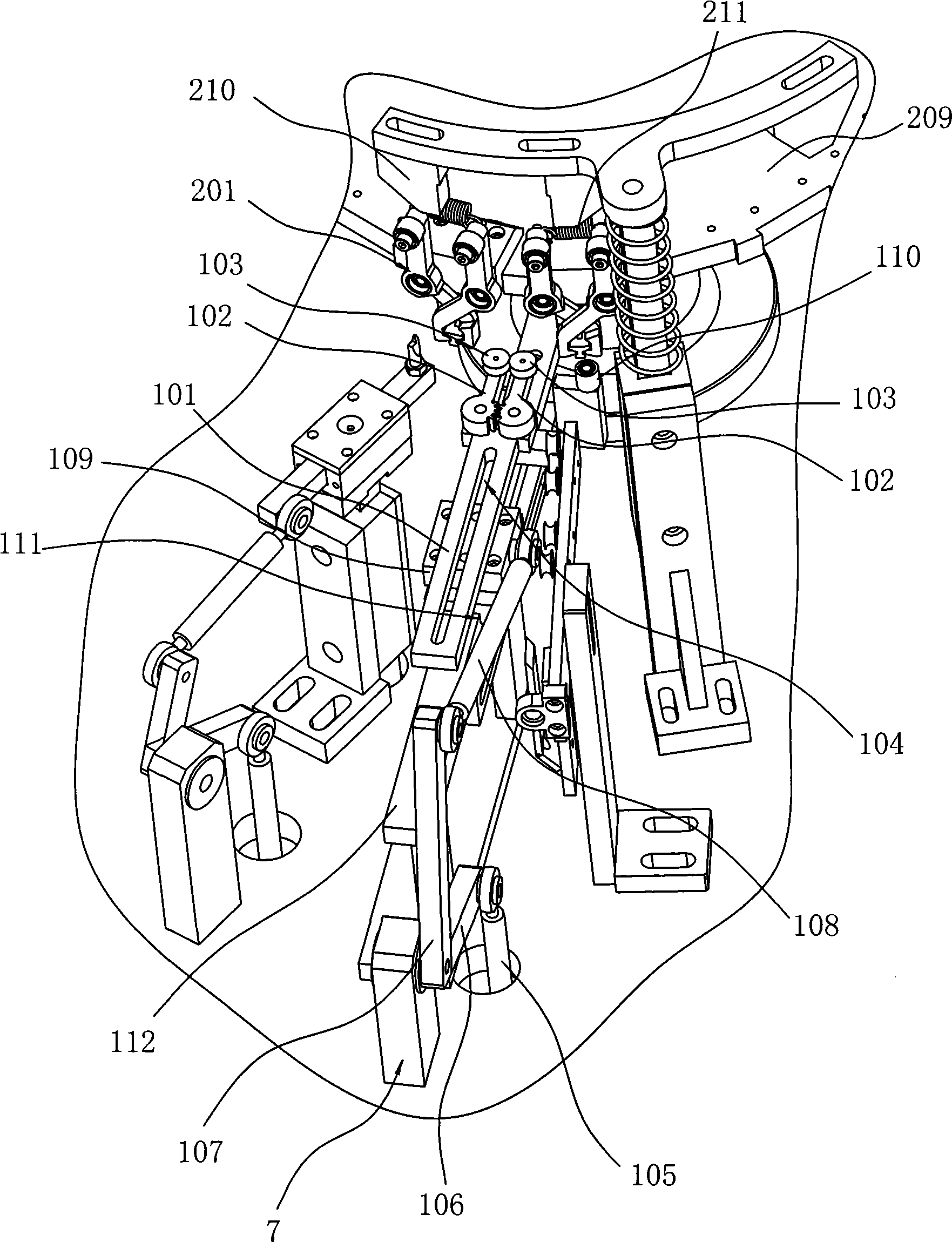

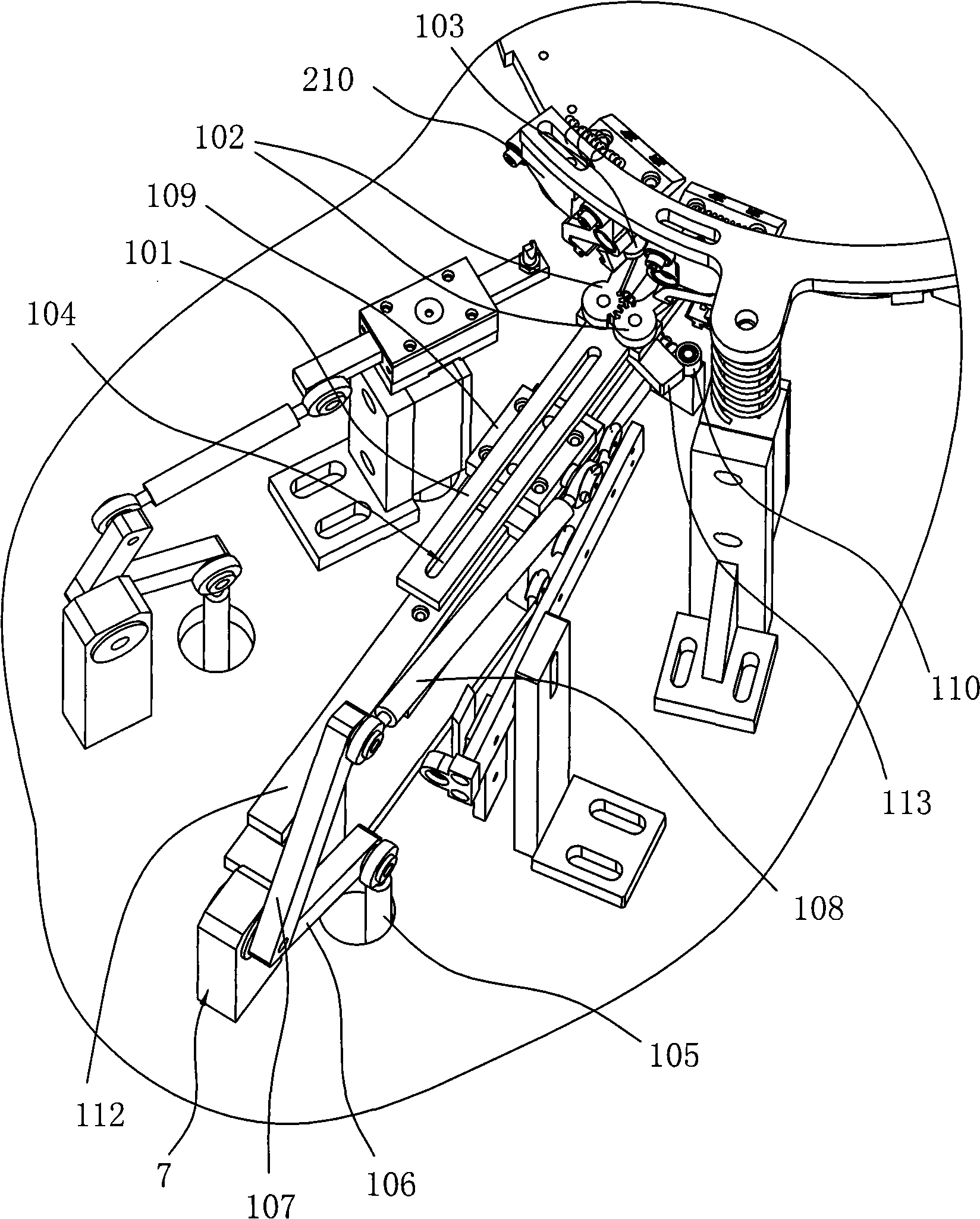

[0081] Example: LED bulb welding machine, such as figure 1 As shown, it includes a frame 7, a power transmission device installed on the frame 7, a bubble feeding device, a wire transmission device and a bubble line connection device that are sequentially provided along the LED bulb welding stroke direction driven by the power transmission device. The bubble delivery device includes a bubble delivery mechanism 8, a bubble foot shaping mechanism 9, and a bubble inspection mechanism that are sequentially provided along the delivery direction of the LED bulb driven by a power transmission device. A wire feeding mechanism, a wire cutting mechanism and a wire stripping mechanism driven by a power transmission device are provided. The bubble wire welding device includes a welding mechanism 3 driven by a power transmission device and a heat-shrinkable tube arranged in sequence along the conveying direction of the LED bulb. mechanism. The wire feeding mechanism includes a wire feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com