Coloring nozzle

A technology of nozzles and components, which is applied in the field of coloring nozzles, can solve problems such as the reduction of wire yield, achieve the effects of reducing consumption, increasing clarity, and preventing dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

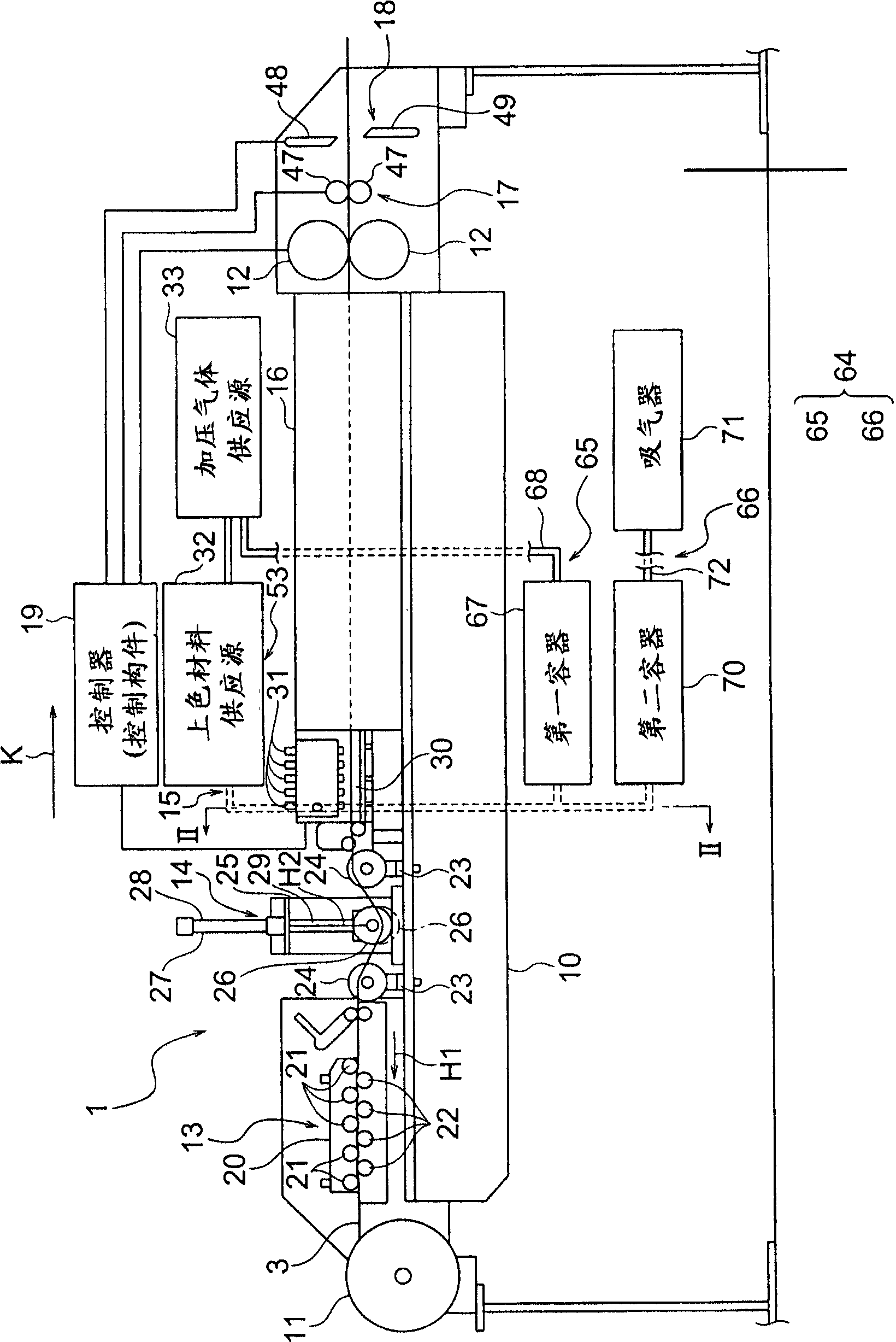

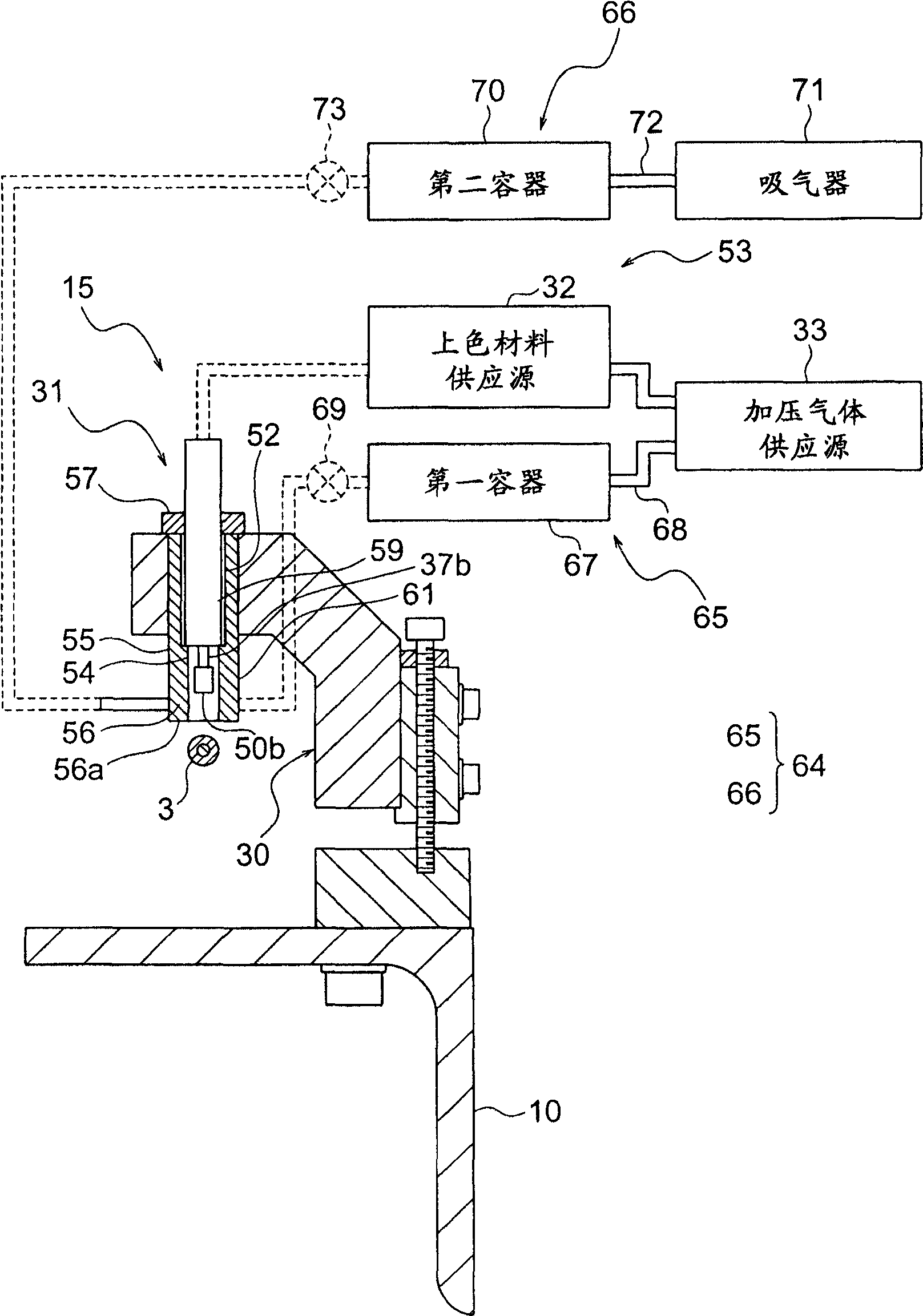

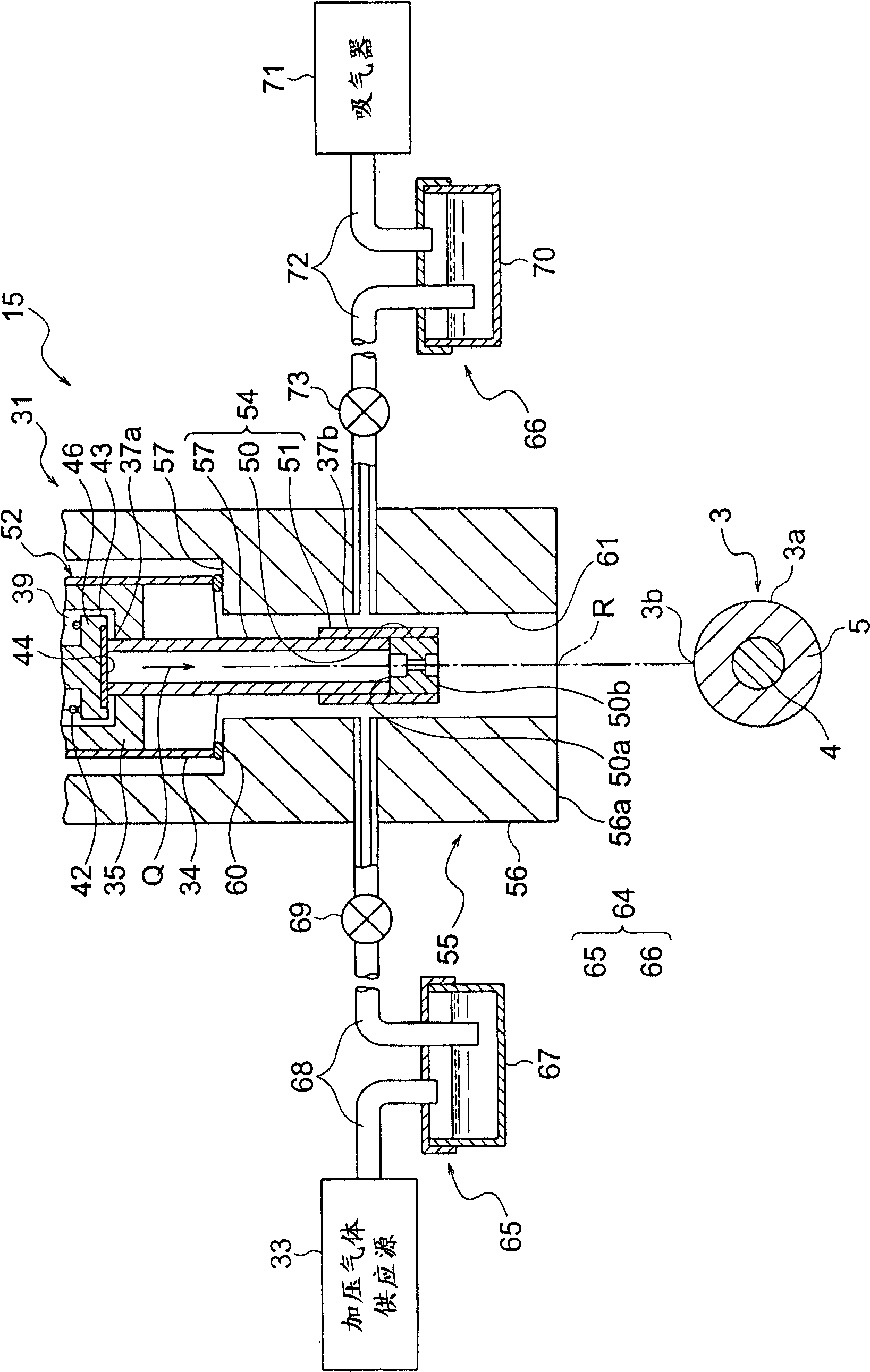

[0048] The following will refer to Figure 1 to Figure 8 The coloring nozzle 31 according to the embodiment of the present invention is explained. image 3 and Figure 4 The illustrated coloring nozzle 31 is mounted on figure 1 The illustrated wire coloring device 1 is configured to color an electric wire 3 as a target object. The coloring device 1 cuts the electric wire 3 to a specific length, and forms a mark 6 on a part of the outer surface 3 a of the electric wire 3 . That is, the coloring device 1 colors, that is, marks the outer surface 3a of the electric wire 3 as a target object.

[0049] The electric wire 3 as a target constitutes a wire harness configured to be provided in a vehicle as a mobile body. like Figure 5 As shown in (a), the electric wire 3 includes a conductive core wire 4 and an insulating sheath 5 . The core wire 4 is formed by winding a plurality of basic electric wires. Basic wires are made of conductive metal. The core wire 4 may consist of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com