Reactive hot-melt composition and molded article using the same

A composition and reactive technology, applied in the field of reactive hot melt compositions, can solve the problems of insufficient development, insufficient shortening of molding cycle, time-consuming cooling and solidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Embodiment 1 (manufacture of reactive hot melt composition)

[0110] 60 parts by mass of crystalline polyester polyol (manufactured by Ube Industries, Ltd., ETERNACOLL (registered trademark) 3010) and 15 parts by mass of amorphous polyester polyol (manufactured by Ube Industries, Ltd., ETERNACOLL (registered trademark) 5011) 25 parts by mass of polycarbonate polyol (manufactured by Ube Industries, Ltd., UH-CARB (registered trademark) 100) were put into a separable flask, replaced with nitrogen, and heated and melted at 120°C. Furthermore, while stirring at a rotation speed of 250 rpm, dehydration treatment was carried out at 120° C. and 50 mmHg for 1 hour, and nitrogen substitution was performed for 10 minutes. Then, the polyol mixture was cooled to 80° C., 1 part by mass of carbon black masterbatch (manufactured by Sumikacolor Co., Ltd., burak SHPA-817, carbon black content: 40%) was added, and stirred and mixed at 150 rpm for 1 hour. Add 4,4'-diphenylmethane diisocya...

Embodiment 2~14 and comparative example 1~3

[0130] Examples 2-14 and Comparative Examples 1-3 (manufacture of reactive hot-melt composition)

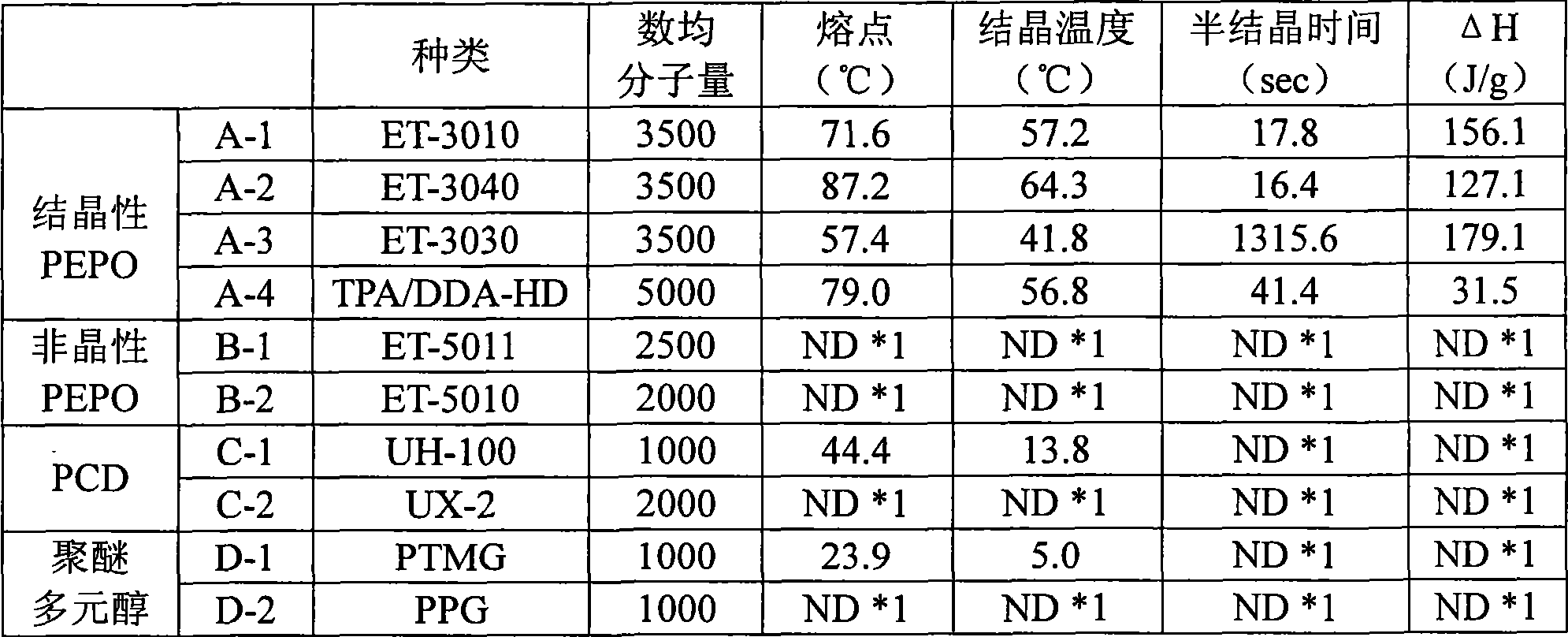

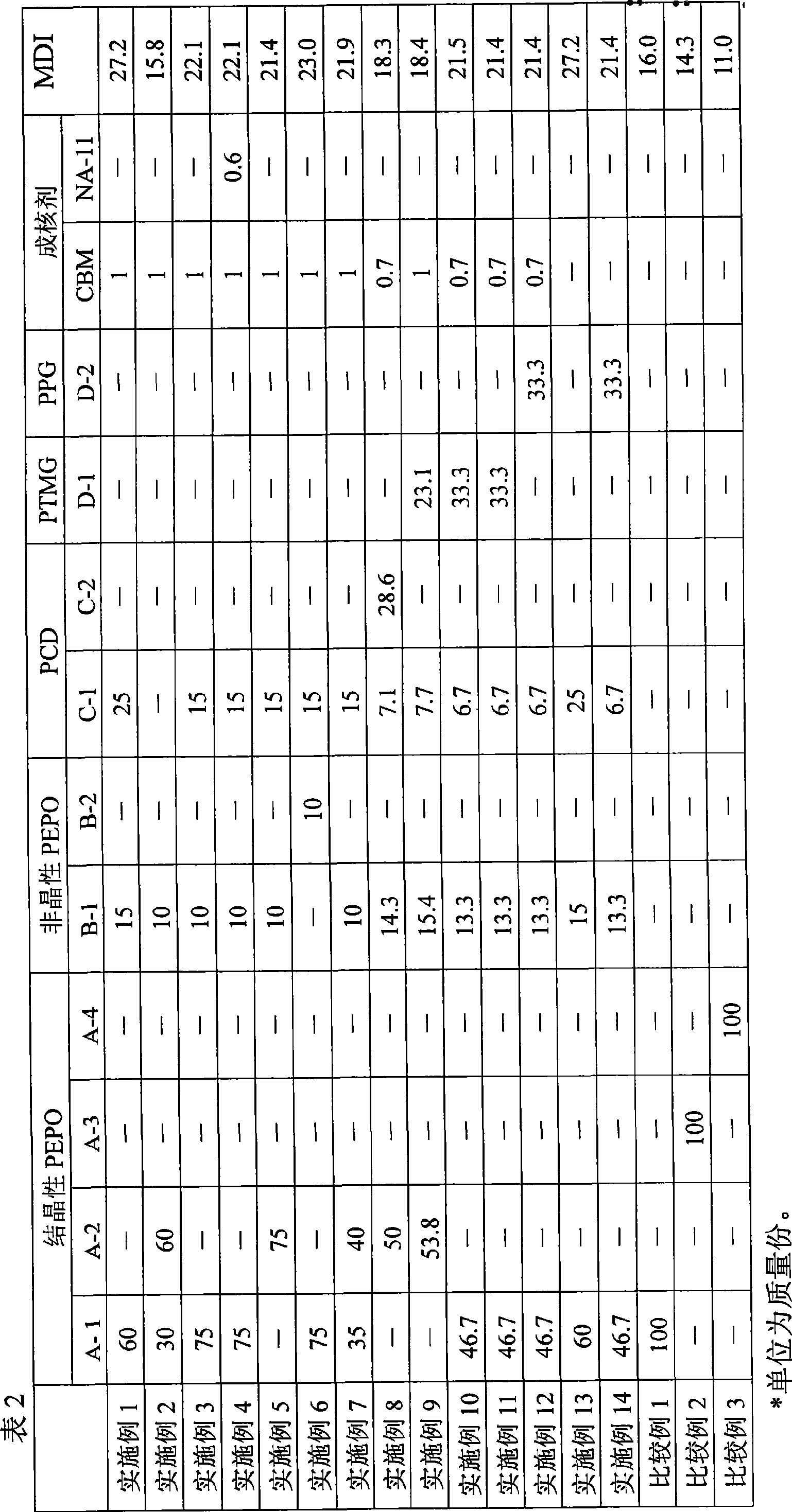

[0131] Except having performed the compounding shown in Table 2 instead of the compounding recipe of Example 1, each component was compounded similarly to Example 1, and it processed similarly, and the reactive hot-melt composition was obtained. The results are shown in Table 2 and Table 3.

[0132]

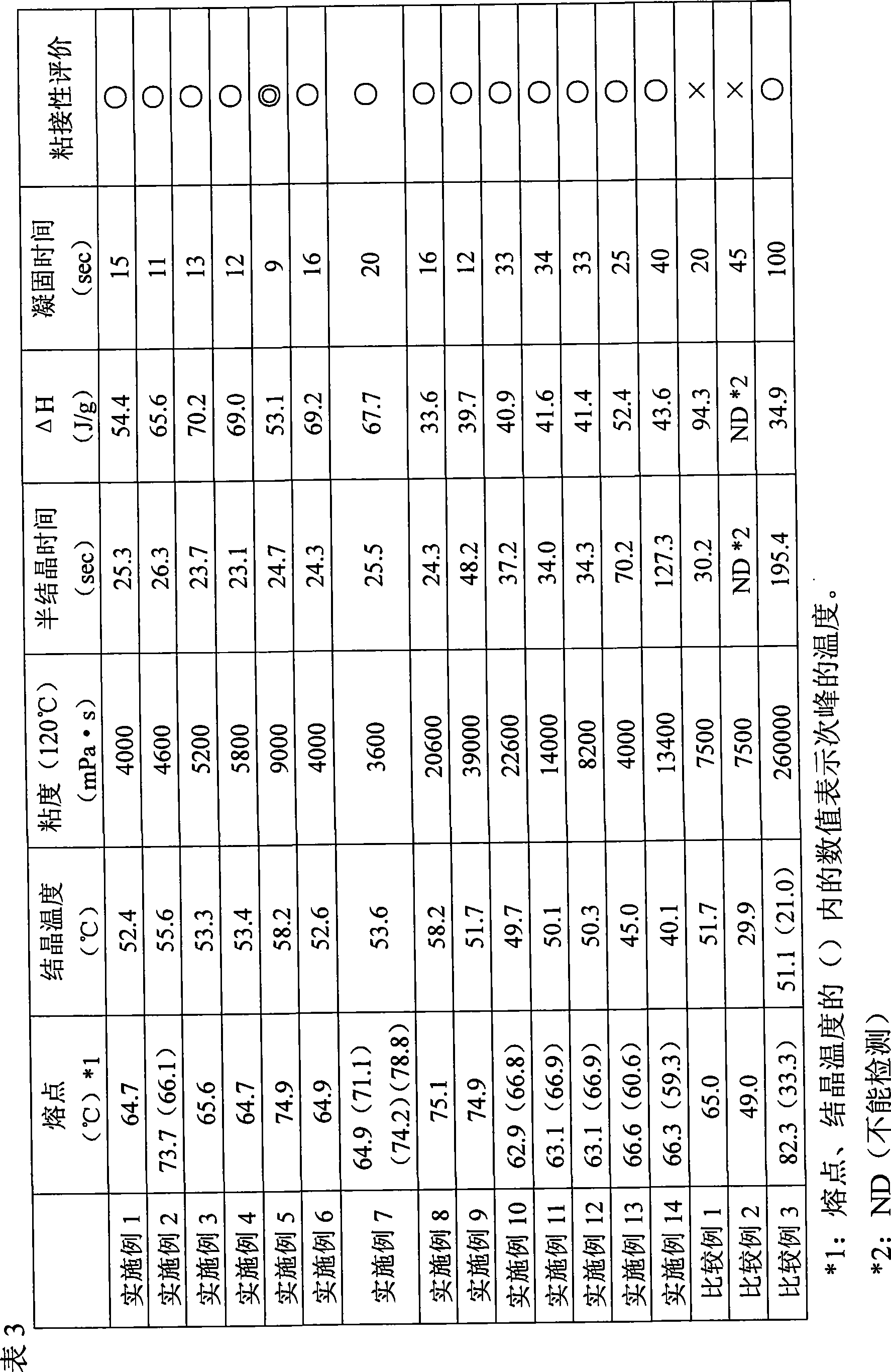

[0133]

[0134] As can be seen from Table 3, the reactive hot-melt composition of the present invention shown in the examples is compared with the composition of Comparative Examples 1-3, there is no big difference in melting point, crystallization temperature, viscosity, but because the half-crystallization time is in Less than 150 seconds, so the cooling and solidification time is shortened to less than 40 seconds, which can shorten the molding cycle. In addition, since the heat of crystallization (ΔH) is in the range of 30 to 80 J / g, especially 30 to 75 J / g, the formabilit...

Embodiment 15

[0135] Example 15 (manufacture of molded article integrating printed circuit board)

[0136] Using the reactive hot-melt composition obtained in Example 1, a molded article into which a printed circuit board was inserted was produced in the following procedure.

[0137] (1) The reactive hot-melt composition was added to a gear pump type glue applicator (set at 120°C for the tank, 120°C for the hose, and 120°C for the nozzle), and melted at 120°C.

[0138] (2) Prepare a mold that can obtain a flat molded product with a length of 50 mm, a width of 30 mm, and a thickness of 4 mm. After applying a release agent, use a support pin to place a printed circuit with a length of 45 mm, a width of 25 mm, and a thickness of 1 mm. The substrate is set in the mold so as to be arranged in the center of the molded product.

[0139] (3) Connect the nozzle of the glue applicator to the injection tank of the mold in a manner that does not leak pressure. Under the conditions of a processing temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com