Reduction of fouling in heat exchangers

A technology of heat exchangers and heat exchange tubes, applied in heat exchange equipment, heat transfer modification, cleaning heat transfer devices, etc., can solve the problems of good heat transfer thickness, resistance to fouling, insufficient, etc., to promote liquid heat transfer , the effect of reducing fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

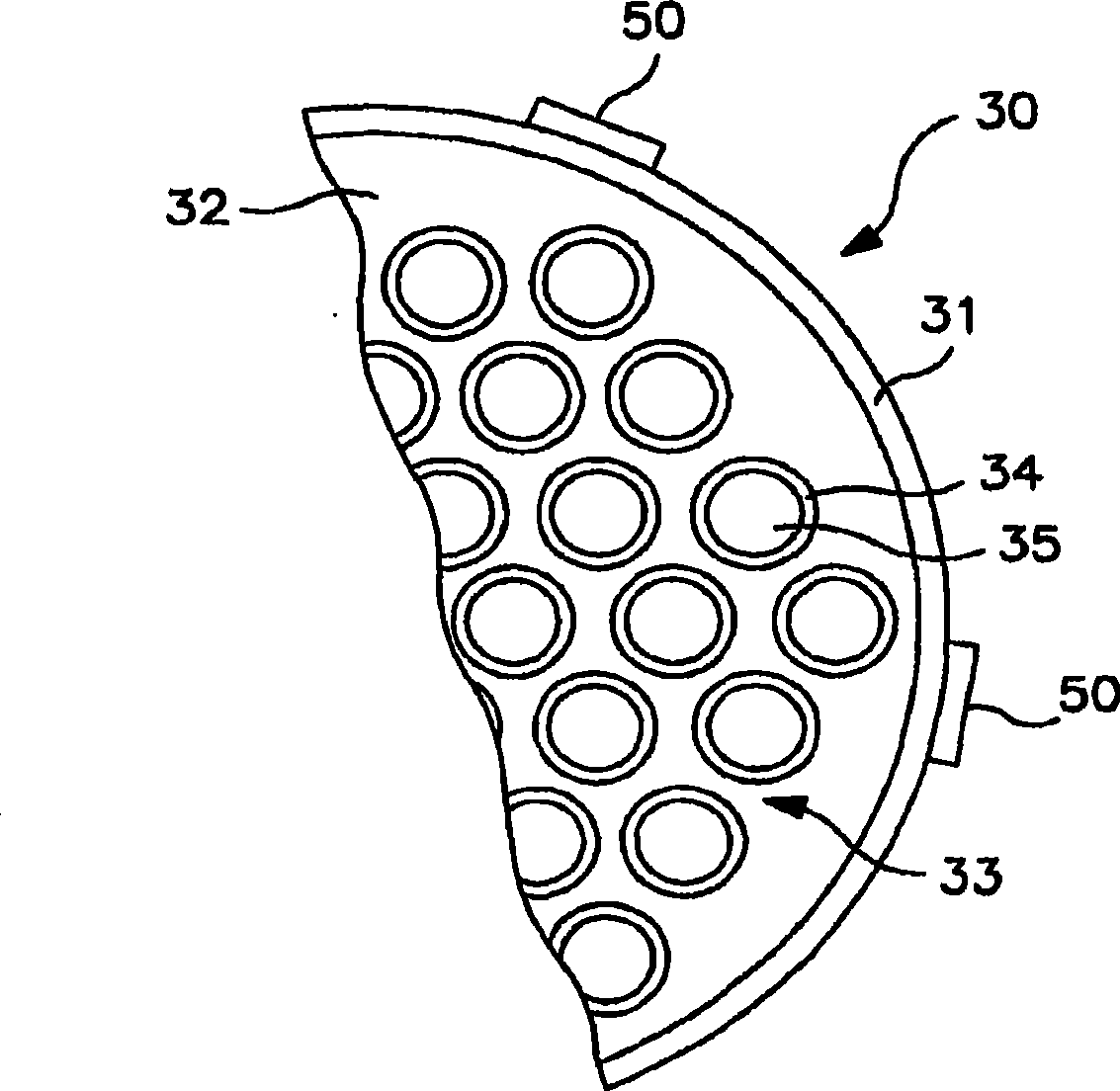

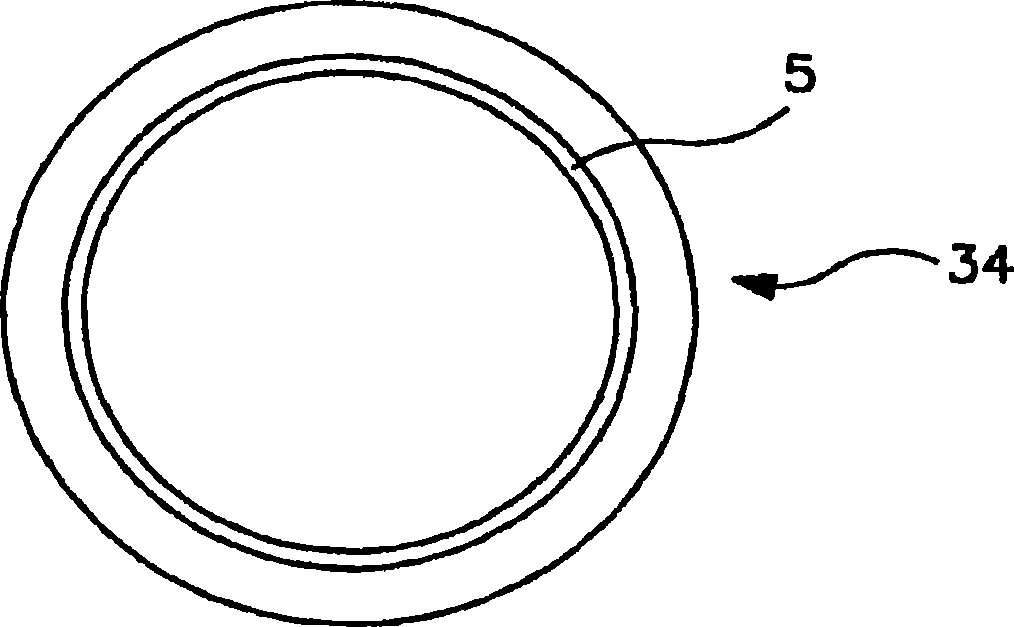

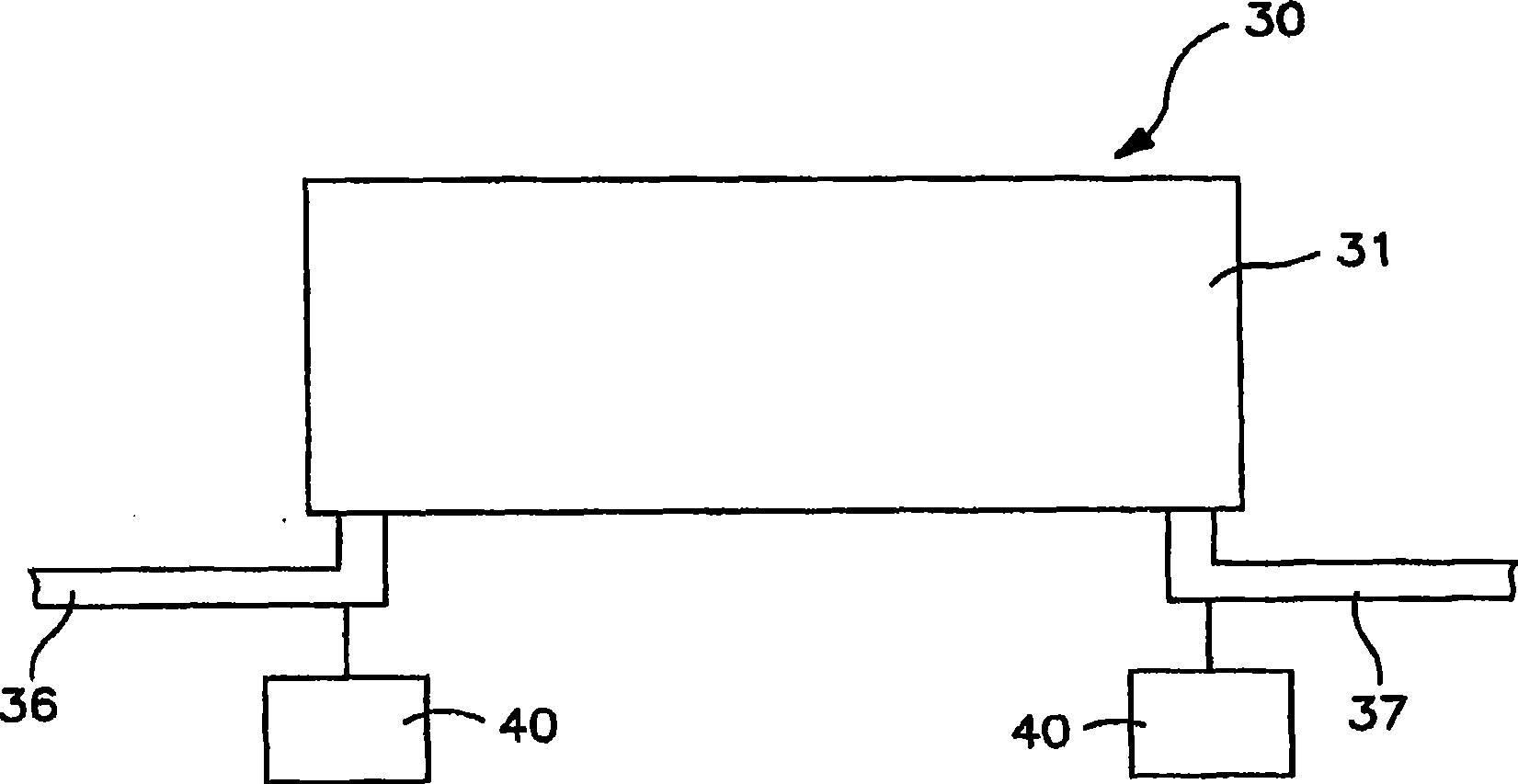

[0022] The invention will now be described in more detail with reference to the accompanying drawings. figure 1is a shell and tube heat exchanger 30 upstream of a furnace (not shown) and employing the principles of the invention. The shell and tube heat exchanger 30 disclosed herein illustrates one application of the present invention for reducing sulfidation or sulfidic corrosion and deposit fouling in refinery and petrochemical applications. Shell and tube exchanger 30 is just one heat transfer component that falls within the scope of the corrosion reduction and fouling mitigation measures of the present invention. The principles of the present invention are intended to be applied to other heat exchangers including, but not limited to, spiral heat exchangers, double tube heat exchangers, and plate and frame heat exchangers having at least one heat transfer element. The principles of the present invention are intended to be applied to other heat transfer components, includin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com