Combined harvester membrane box feed quantity testing method, device and feed quantity sensor

A technology of combine harvester and test method, which is applied in the field of combined harvester feed rate test method, device and feed rate sensor to achieve the effects of convenient installation, high test performance and improved test performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

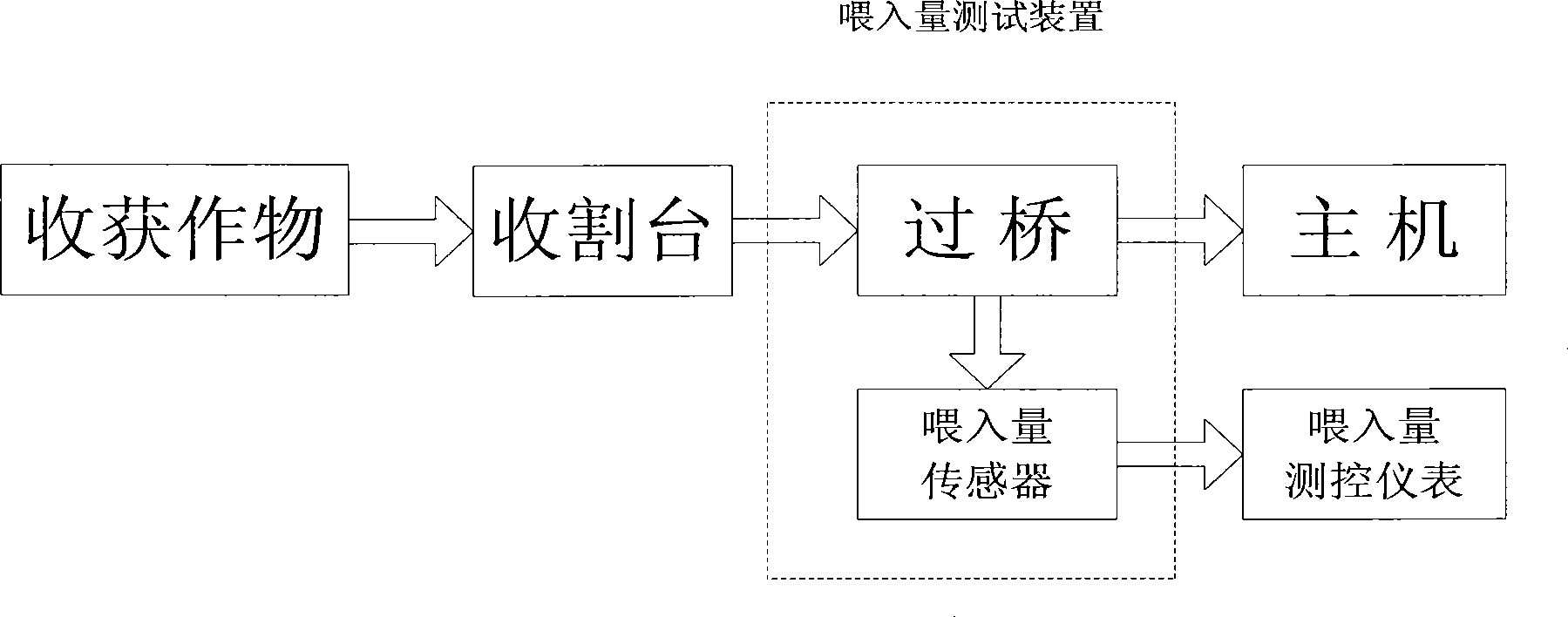

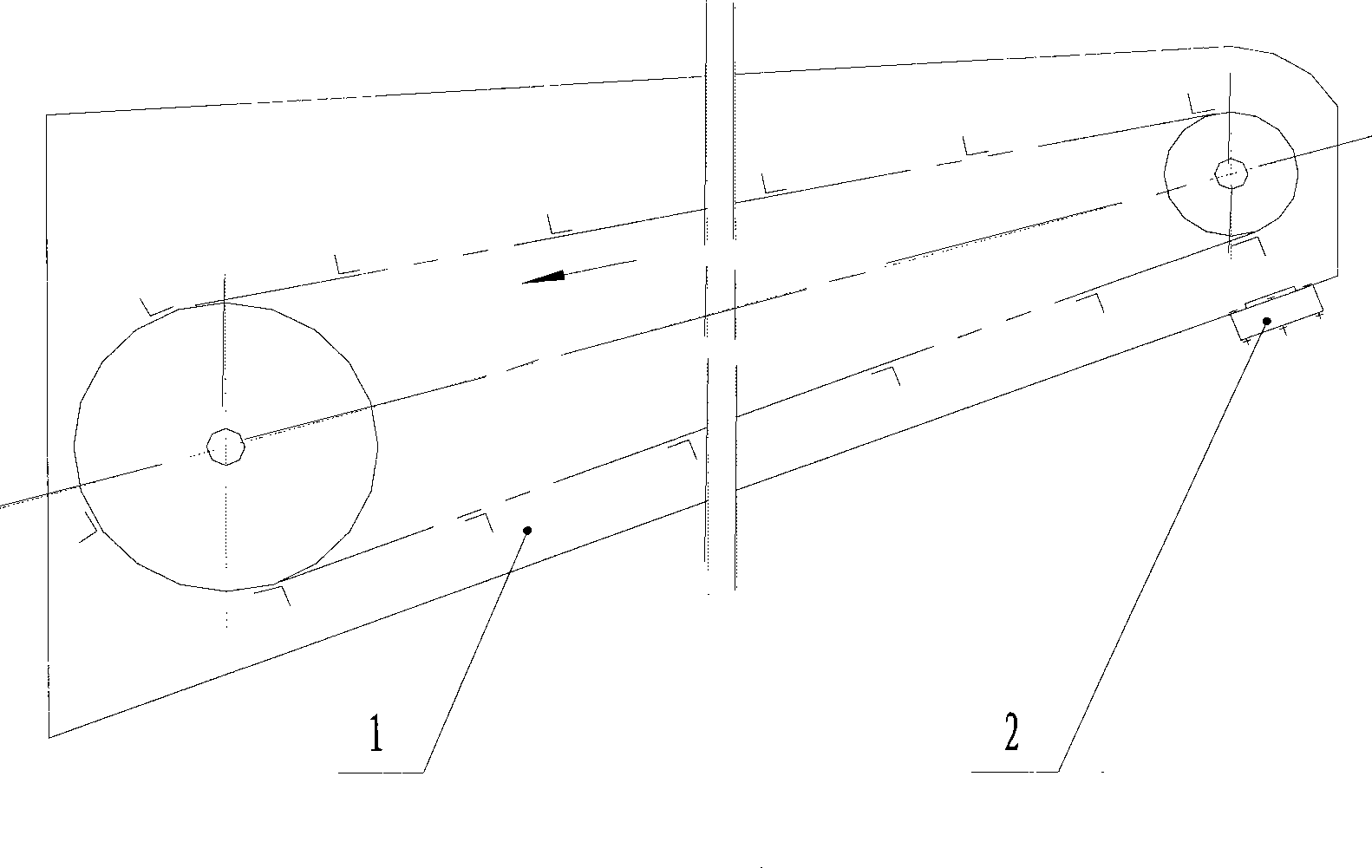

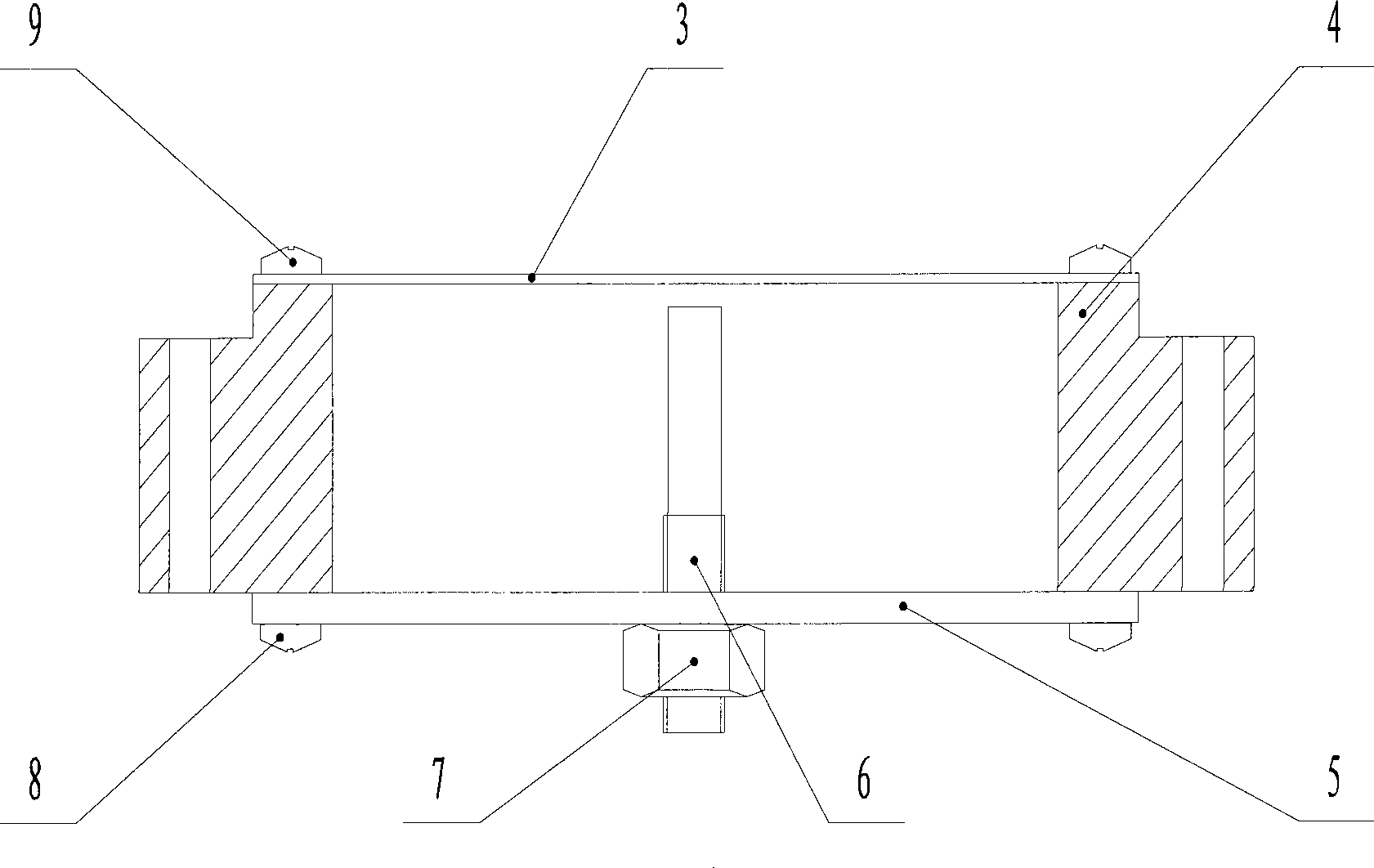

[0021] The method for testing the feeding amount of the bellows according to the present invention: the bellows is composed of a diaphragm and a sensor seat, a sensor for testing the displacement of the diaphragm is arranged in the bellows to form a feeding amount sensor of the bellows, and the feeding amount sensor of the bellows is installed The bottom plate at the bridge exit of the combine harvester bears the extrusion force of the bridge conveying and feeding crops, and converts the extrusion force (diaphragm displacement) signal into an electrical signal to test the feed amount of the combine harvester. This method can also be called the diaphragm displacement feeding amount test method, and its working principle is as follows: figure 1 Shown:

[0022] When the combine harvester is harvesting in the field, the mature crops cut by the harvesting table are transported to the main engine through the bridge for threshing, separation and cleaning, and the crop grains are harv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com