Seedling cultivation method for sea-tangle

A technology of kelp and light intensity, applied in the fields of botanical equipment and methods, seaweed cultivation, horticulture, etc., can solve the problems of time-consuming, laborious, high cost, and difficult to control, so as to reduce high cost, ensure healthy growth, and be easy to select and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

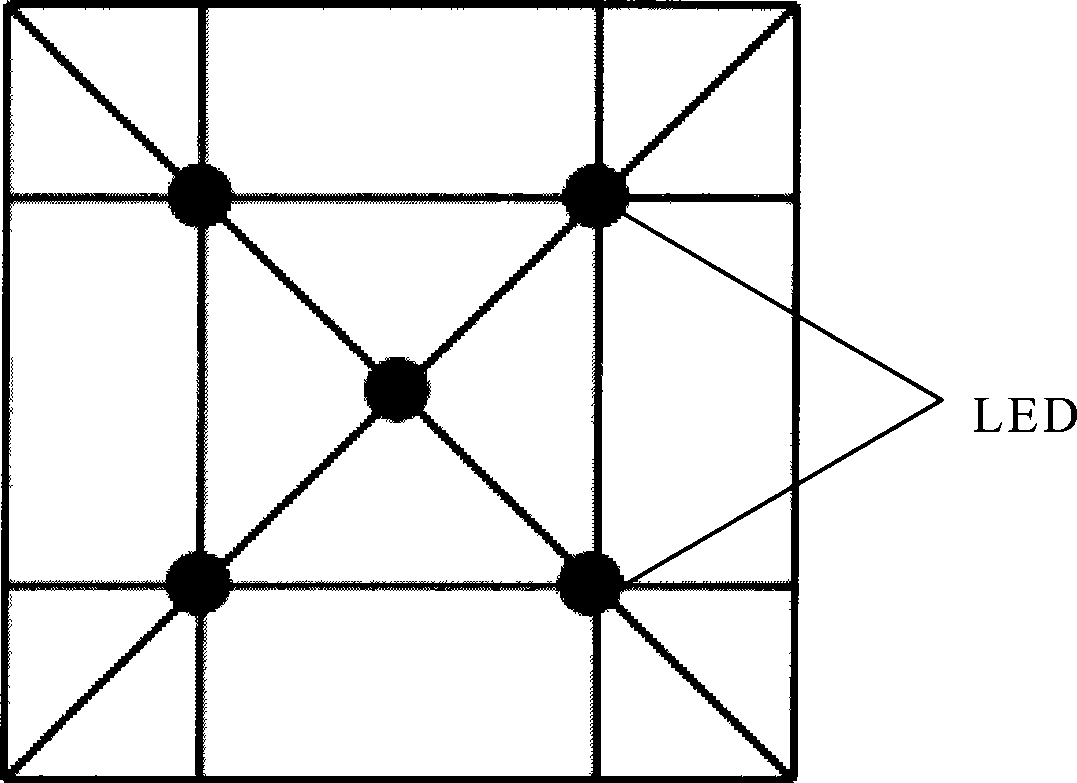

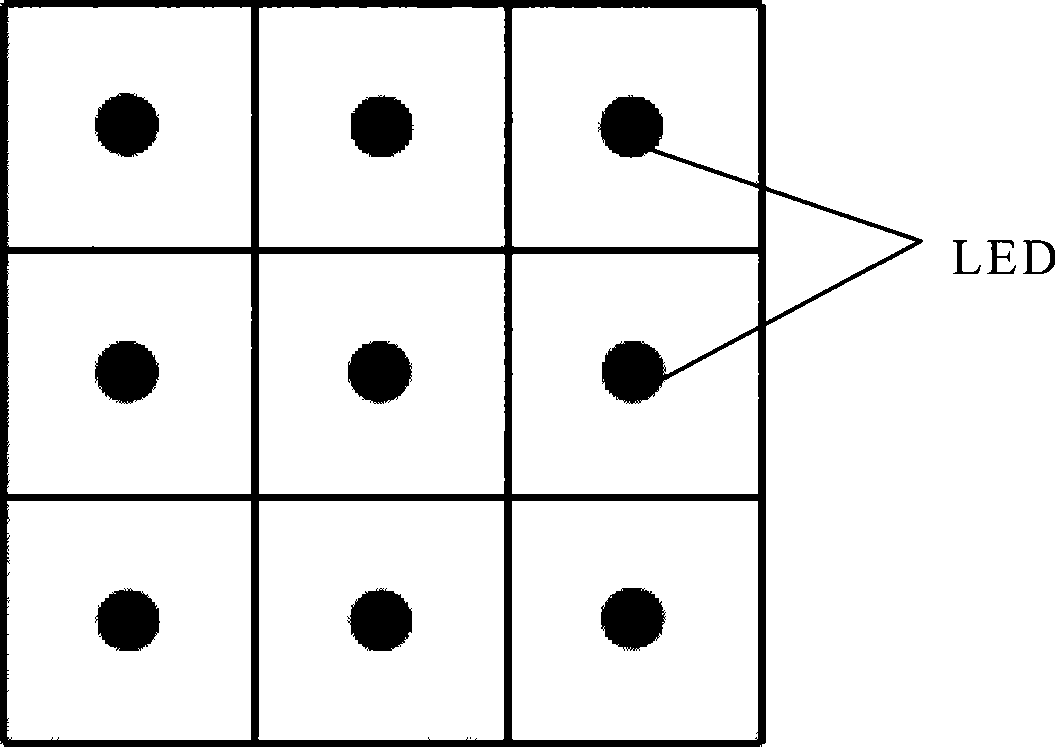

[0026] Embodiment 1: Said embodiment kelp seedling cultivation is carried out in a water tank, and the temperature of the water body in the water tank is controlled at several degrees Celsius. Brown ropes are evenly laid on the bottom of the water tank, and a submersible pump is placed inside the water tank to make the water in the water tank flow. A white LED light, a blue LED light and a red LED light are arranged on the top of the water tank as light sources of white light, blue light and red light respectively. Among them, the layout diagram of the white LED lights is as follows: figure 1 As shown, there are 5 LED lights in each group. The layout diagram of blue LED light and red LED light is as follows: figure 2 As shown, each group has 9 LED lights, and the photoperiod of each light quality is 8h light (L) / 16h dark (D). The whole seedling period includes the following four stages:

[0027] a1. Collect zoospores, first irradiate and cultivate them with white light wi...

Embodiment 2

[0032]Embodiment 2: The equipment used in this embodiment is the same as that of Embodiment 1, the difference is that the temperature of the water body in the water tank of this embodiment is controlled at 13°C.

[0033] The whole seedling period includes the following four stages:

[0034] a2. Collect zoospores, first irradiate and cultivate them with white light with an illumination intensity of 15001x for 12 days, and the zoospores form gametophytes. At this time, a small amount of female gametophytes may ovulate to form microsporophytes.

[0035] b2, then use blue light with an illumination intensity of 30001x to cultivate, cultivate for 4 days, and more than 95% of the female gametophytes ovulate to form microspores; continue to cultivate with blue light for another 11 days, and the average size of the microspores is 456um in length and 98um in width.

[0036] c2. In order to slow down the growth of microspores and reduce the occurrence of diseases, after 15 days of culti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com