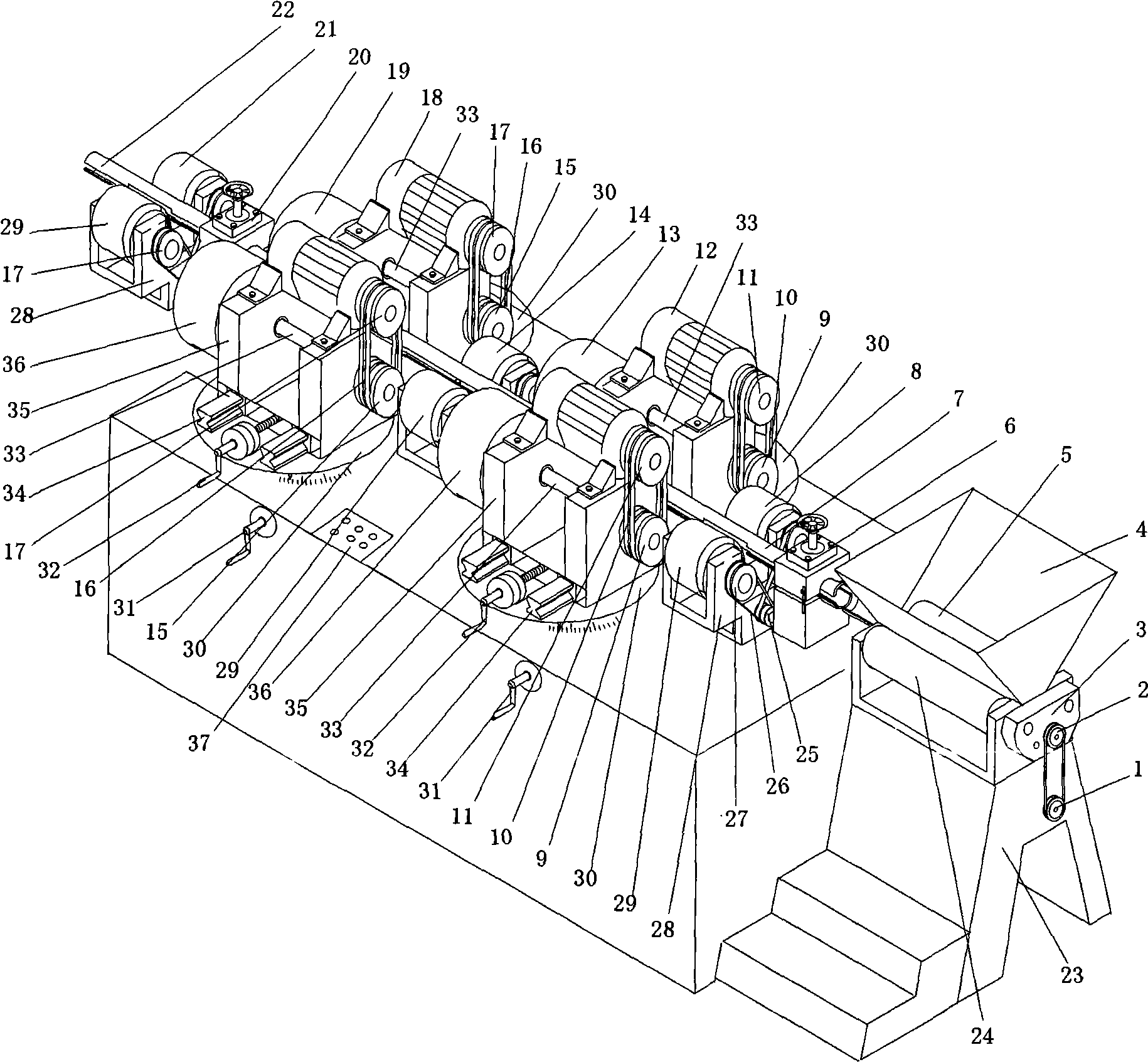

Full automatic round stick sanding and polishing equipment

A fully automatic, round rod technology, applied in grinding/polishing equipment, metal processing equipment, machine tools designed for grinding workpiece rotating surfaces, etc., can solve poor quality, failure to meet speed and quality requirements, slow speed, etc. problem, to achieve the effect of fast speed, lower processing cost and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

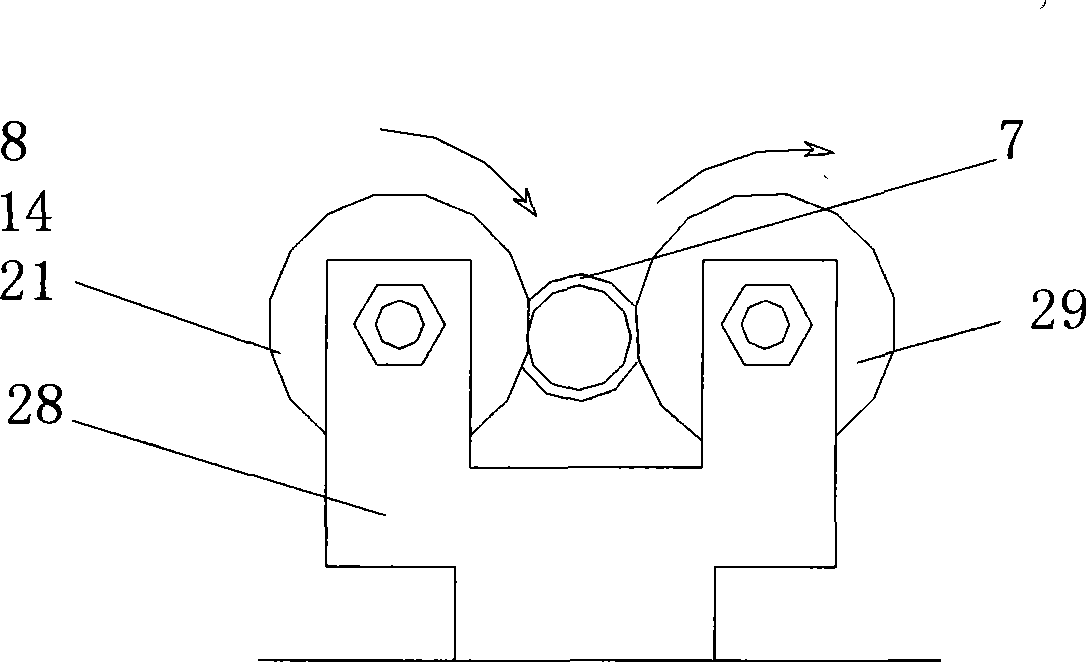

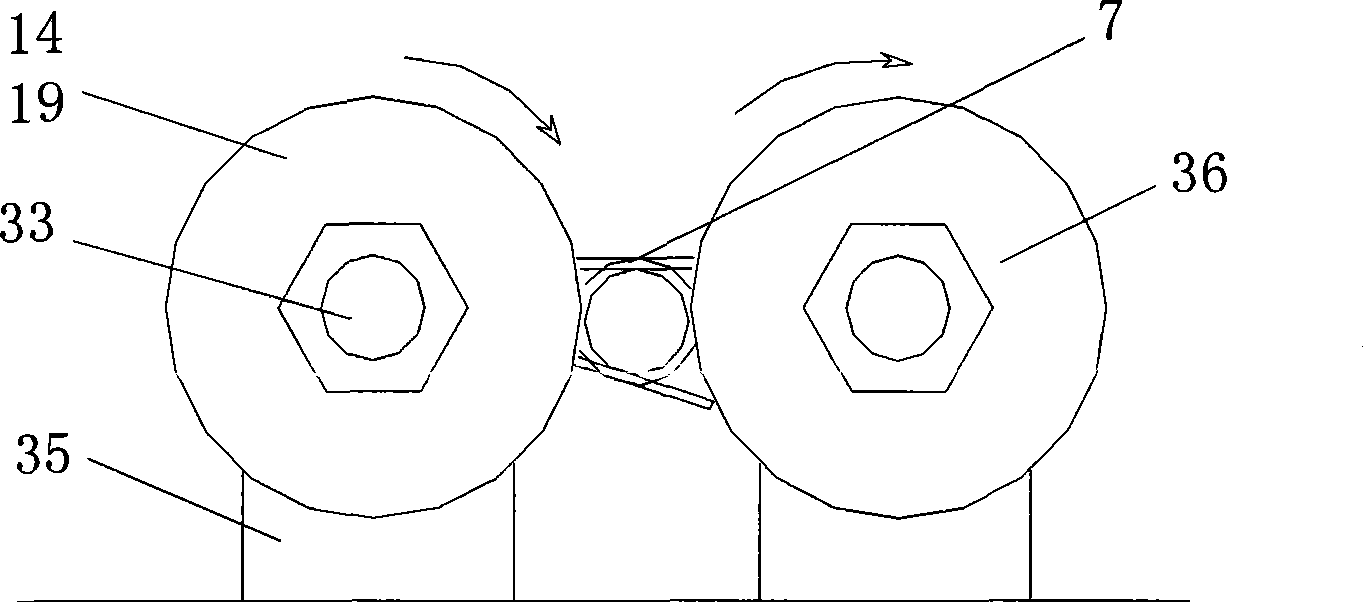

[0010] A fully automatic round bar grinding and polishing equipment is mainly driven by the belt pulley of the motor (1) in the base (23), the spiral conveying roller connected in the belt pulley (2) driven by the V-belt and the internal gear of the gearbox (3) The screw conveying rollers (5), (24) rotate, and the round rods falling from the storage hopper (4) enter the conduit (7) through the hole adjuster (6) and are conveyed by the spiral conveying wheel (29) Grinding by the grinding wheel (8), the pulley (11) on the motor (12) drives the pulley (9) to rotate through the belt (10), and the shaft rod (33) connected on the pulley (9) drives the guide pulley (36 ) and the grinding wheel (13) rotate to complete the rough grinding work of the first step; enter the grinding wheel (14) and the conveying wheel (29) to carry out the fine grinding of the first step, while grinding the stick body by the conveying wheel (29) Transmission to the pulley (17) on the motor (18), the pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com