Special combined front suspension for large-scale bus

A composite, front suspension technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of poor ride comfort, difficulty in popularization, high rigidity, etc., to achieve high-frequency vibration isolation and good ride comfort sex, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

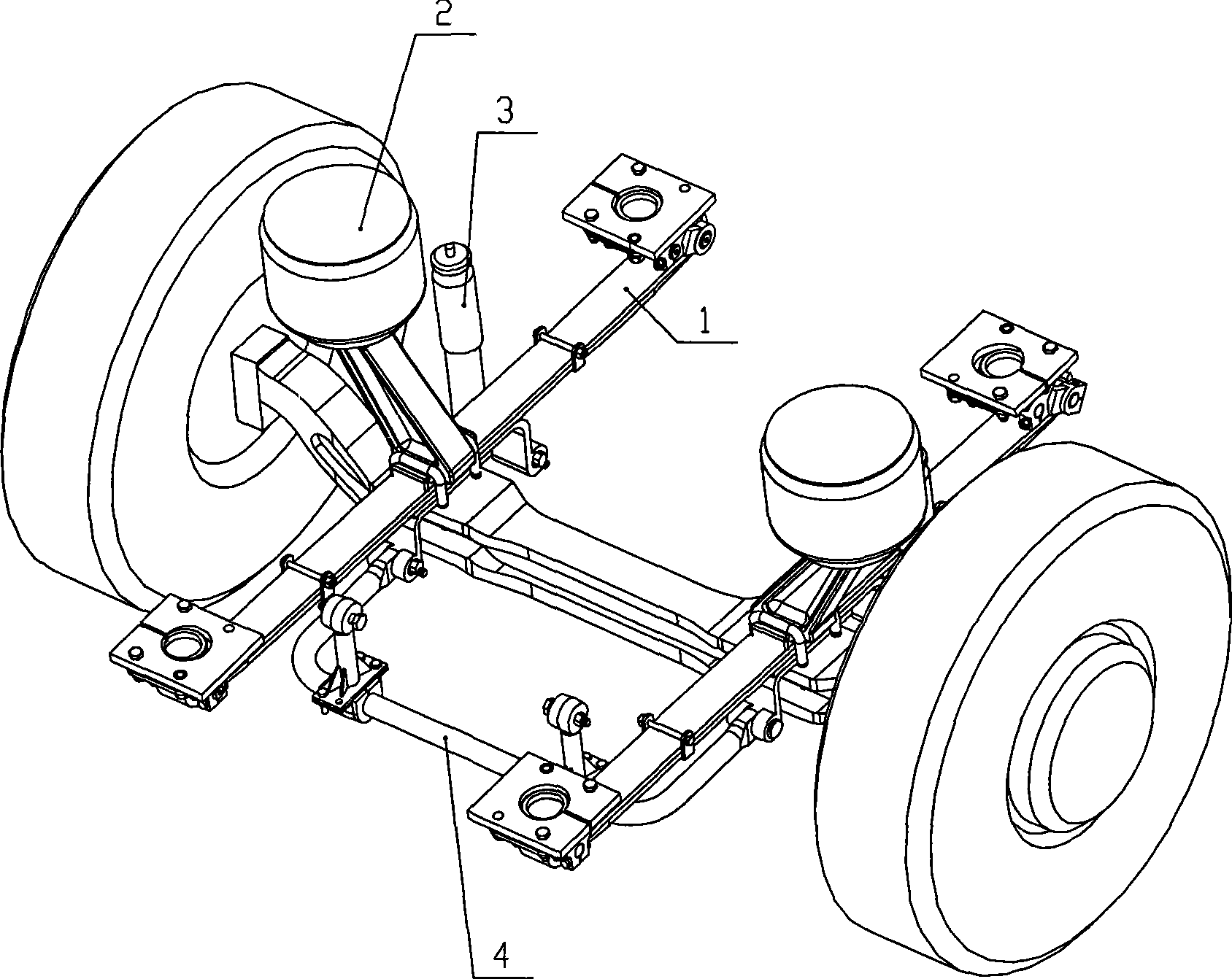

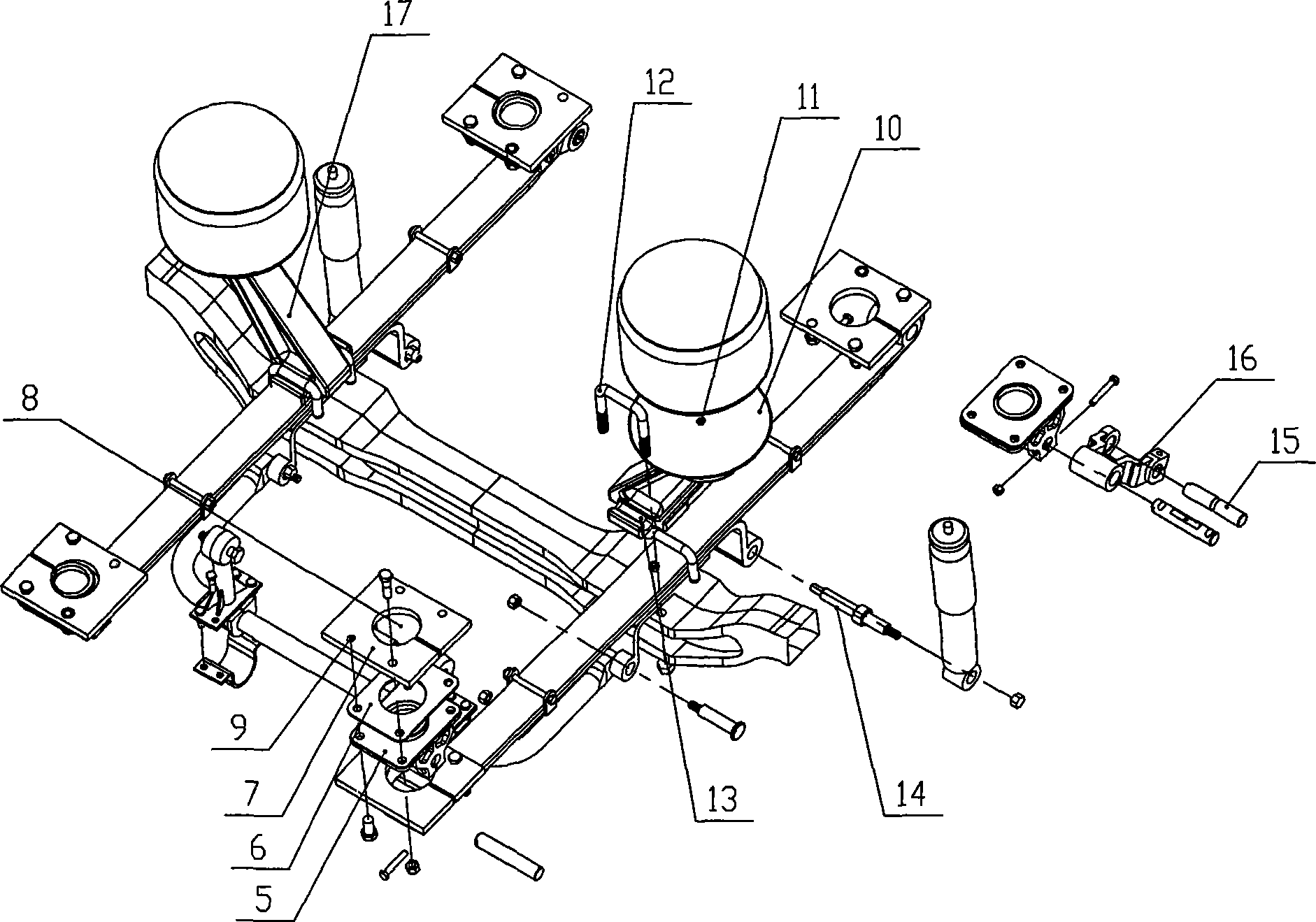

[0025] Below in conjunction with accompanying drawing, the present invention will be described in further detail with 12 meters of two-step bus prototype examples.

[0026] Such as figure 1 , figure 2 As shown, the guide leaf spring 1 is respectively provided with an air spring airbag 3 , an air spring airbag support 17 , a shock absorber 3 and a lateral stabilizing torsion bar 4 .

[0027] Guide leaf spring 1 is made up of the main piece that the leaf spring of identical front axle load-carrying capacity hangs and the hook piece of the main piece that plays insurance role, and two leaf springs up and down are jointly used as guide element.

[0028] The two ends of the main piece of the guide leaf spring 1 are provided with leaf spring supports 5 respectively, and the polyurethane backing plates 6 and the bottom frame support back plate 7 are arranged on the top of the leaf spring support 5 in sequence, and the center of the bottom frame support back plate 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com