Full-automatic safety dustbin

A trash can, fully automatic technology, applied in the direction of trash cans, garbage collection, household appliances, etc., can solve the problem of rare trash can products, achieve convenient and fast cleaning work, simple and convenient operation, and reduce exposure to pollutants. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

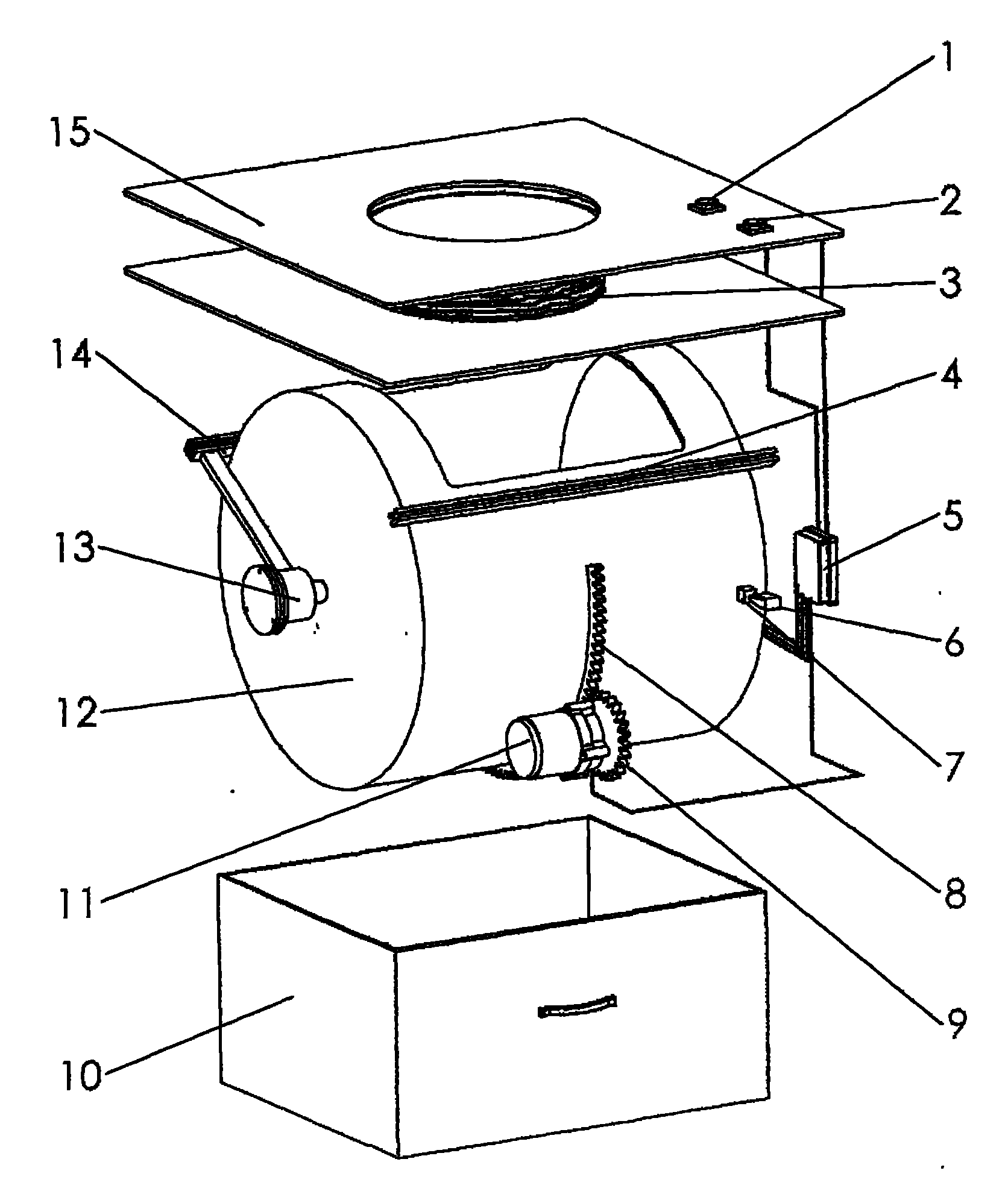

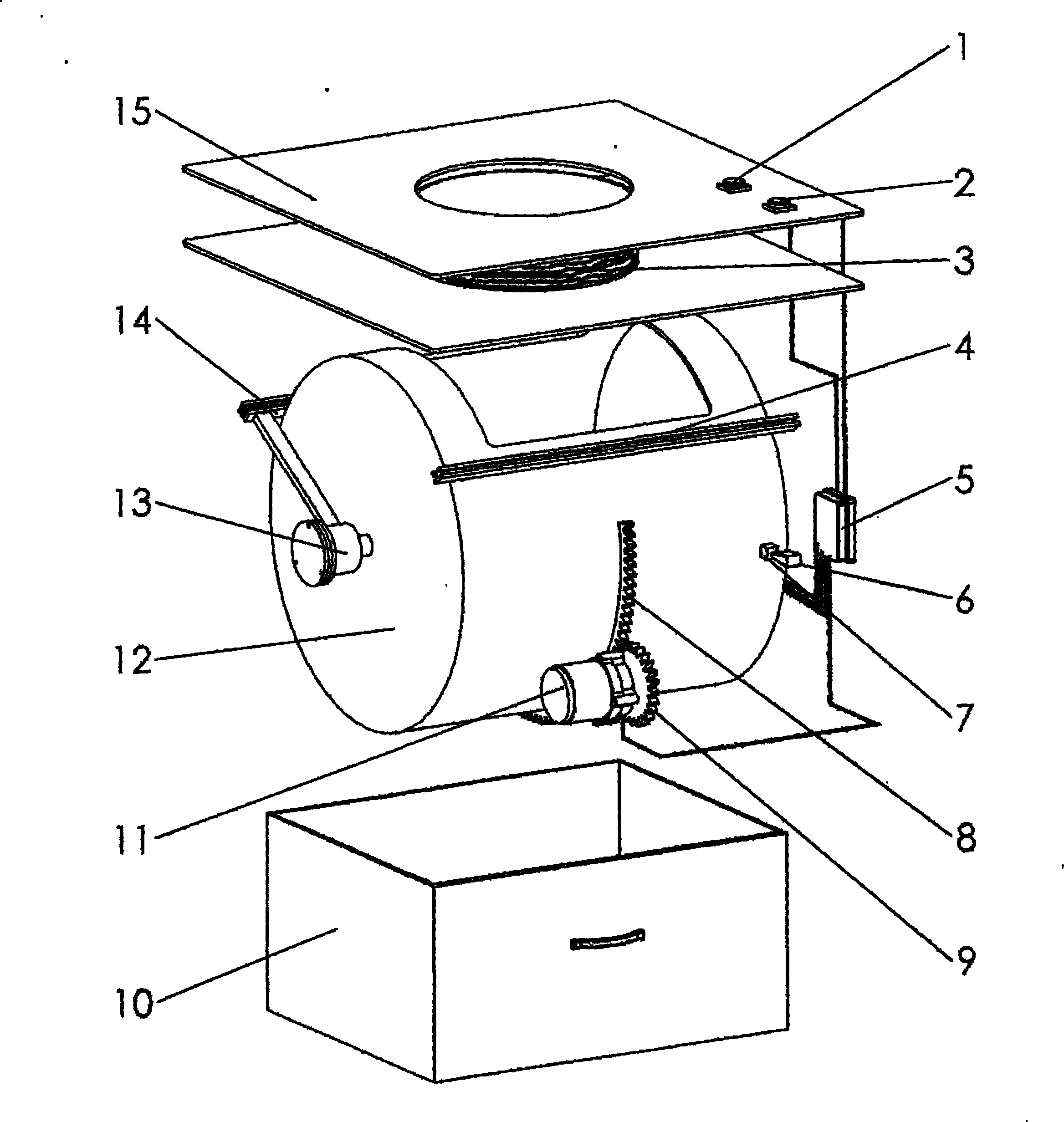

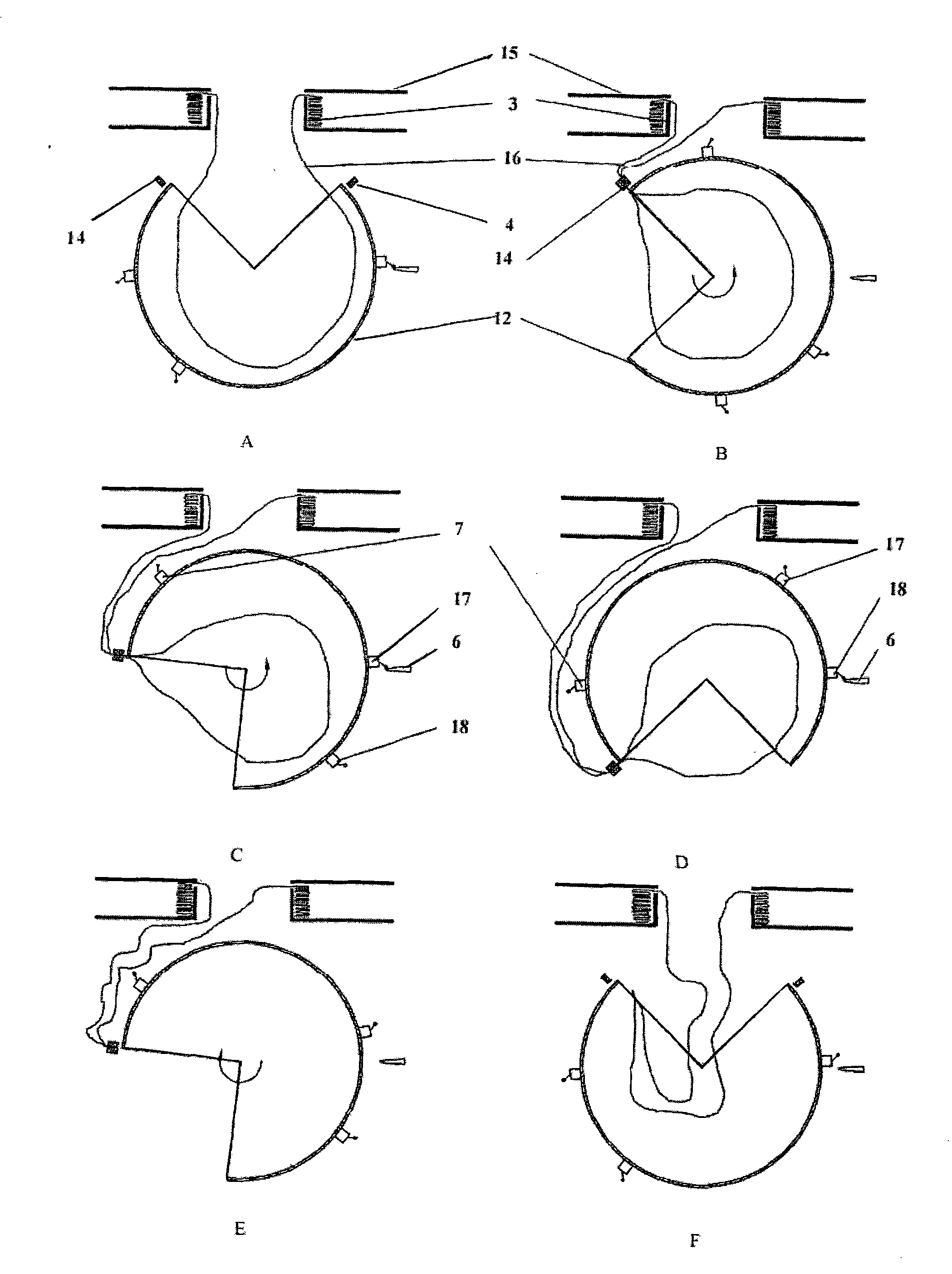

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

[0016] As shown in Figure 1, the opening on the cylindrical surface of the temporary storage bin 12 placed horizontally, the middle part of the unopened cylindrical surface is equipped with a rack 8 with a central angle of 120 ° arc, the rack 8 and the gear driven by the motor 11 9 phase meshing, there are sleeves 13 with built-in coil springs on both sides of the temporary storage bin 12, and the temporary storage bin 12 can rotate around the central axis of the sleeves 13 on both sides; a fixed heat-sealing strip 4 is installed on one side of the opening, and a movable heat-sealing strip 14 is connected with the sleeve through the connecting rod, and can rotate around the central axis. The top of the temporary storage bin 12 is an "I"-shaped neck 3, and there is a gap for pulling plastic bags above the neck; the bottom of the temporary storage bin 12 is a The storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com