Argon blowing automatic connecting mechanism for steel melting technique

An automatic connection and process technology, applied in the field of auxiliary tool manufacturing, can solve the problems of easy melting of rubber gaskets, low work efficiency, increased production costs, etc., to achieve good sealing effect, increase production costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

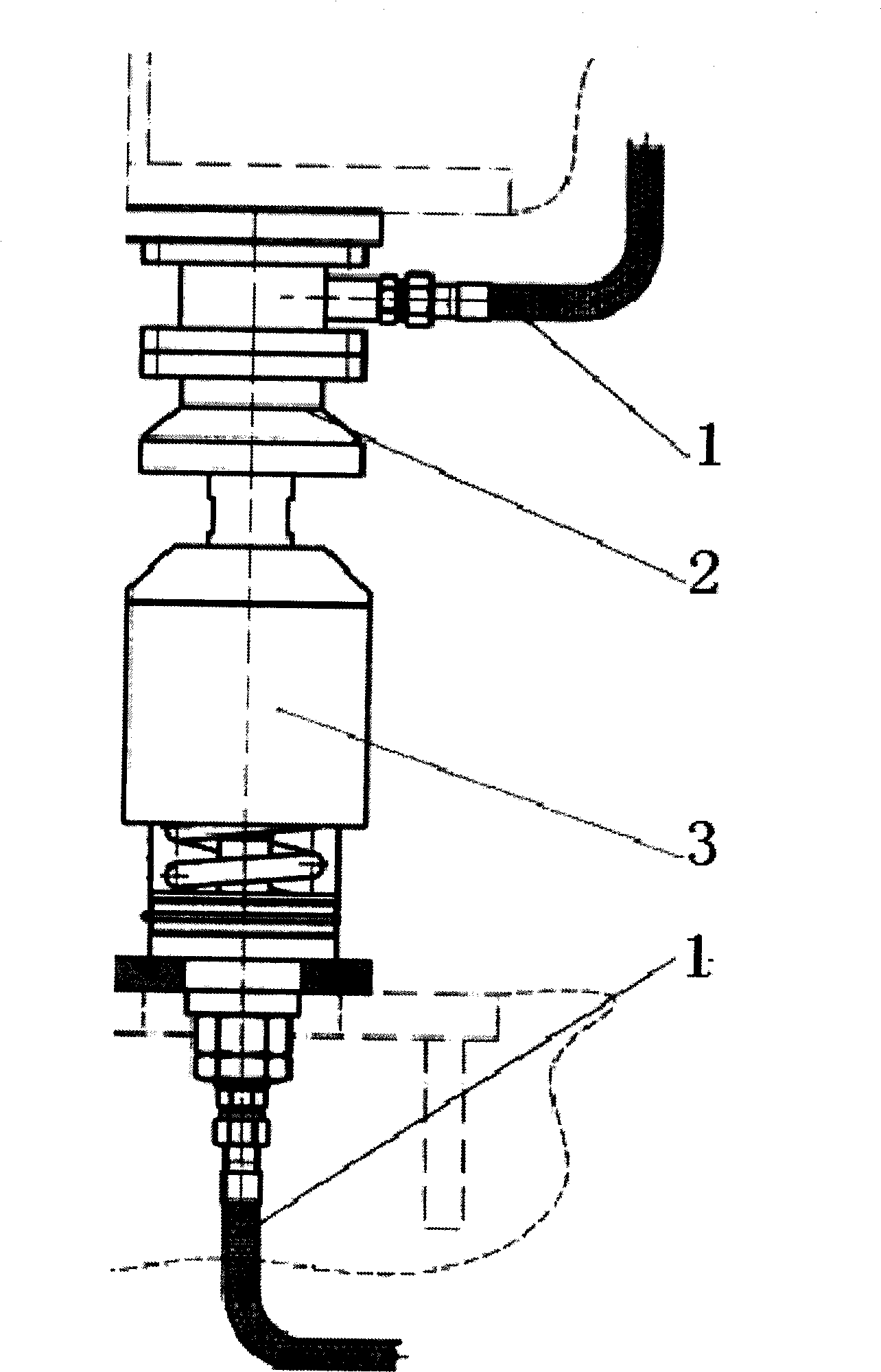

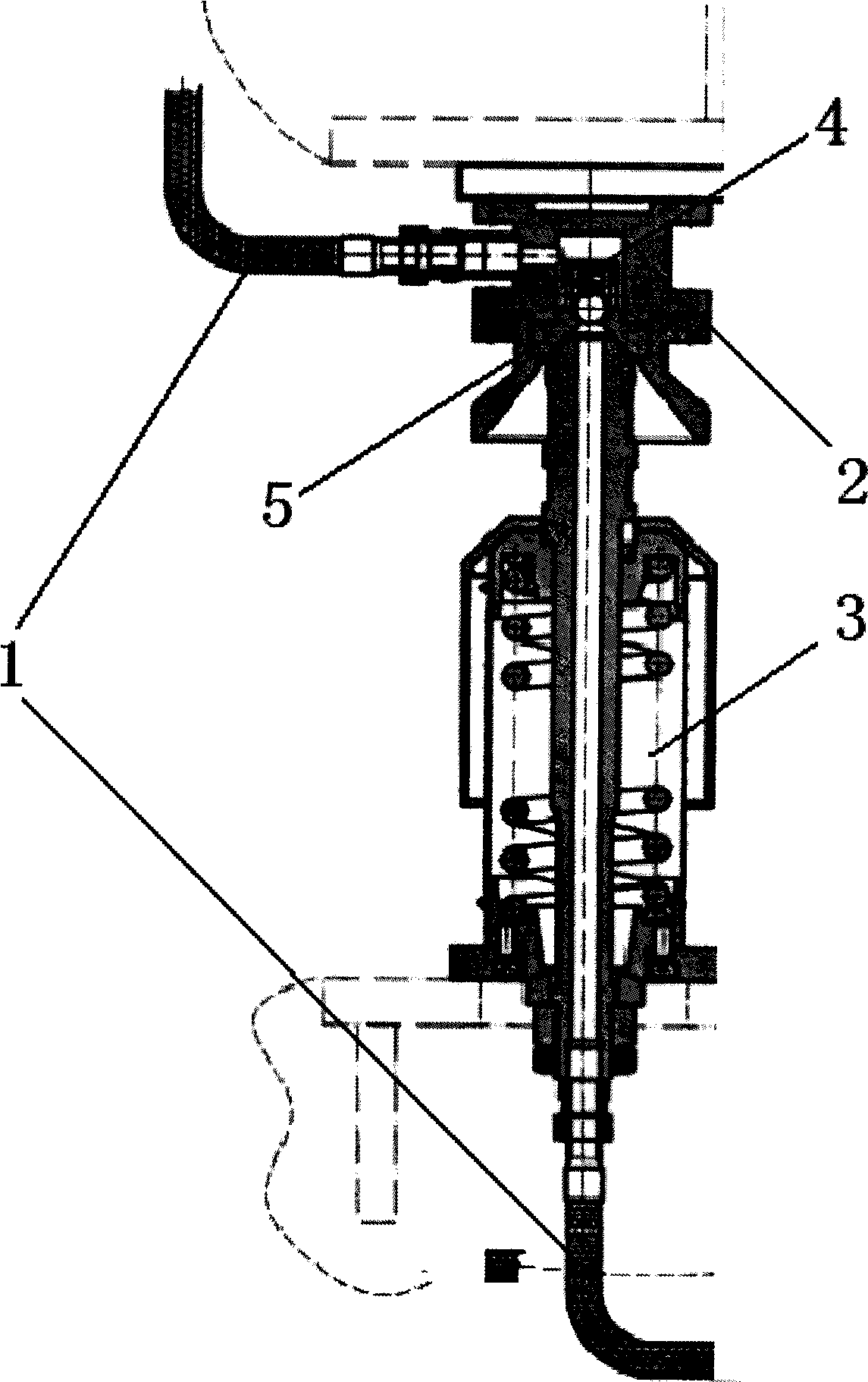

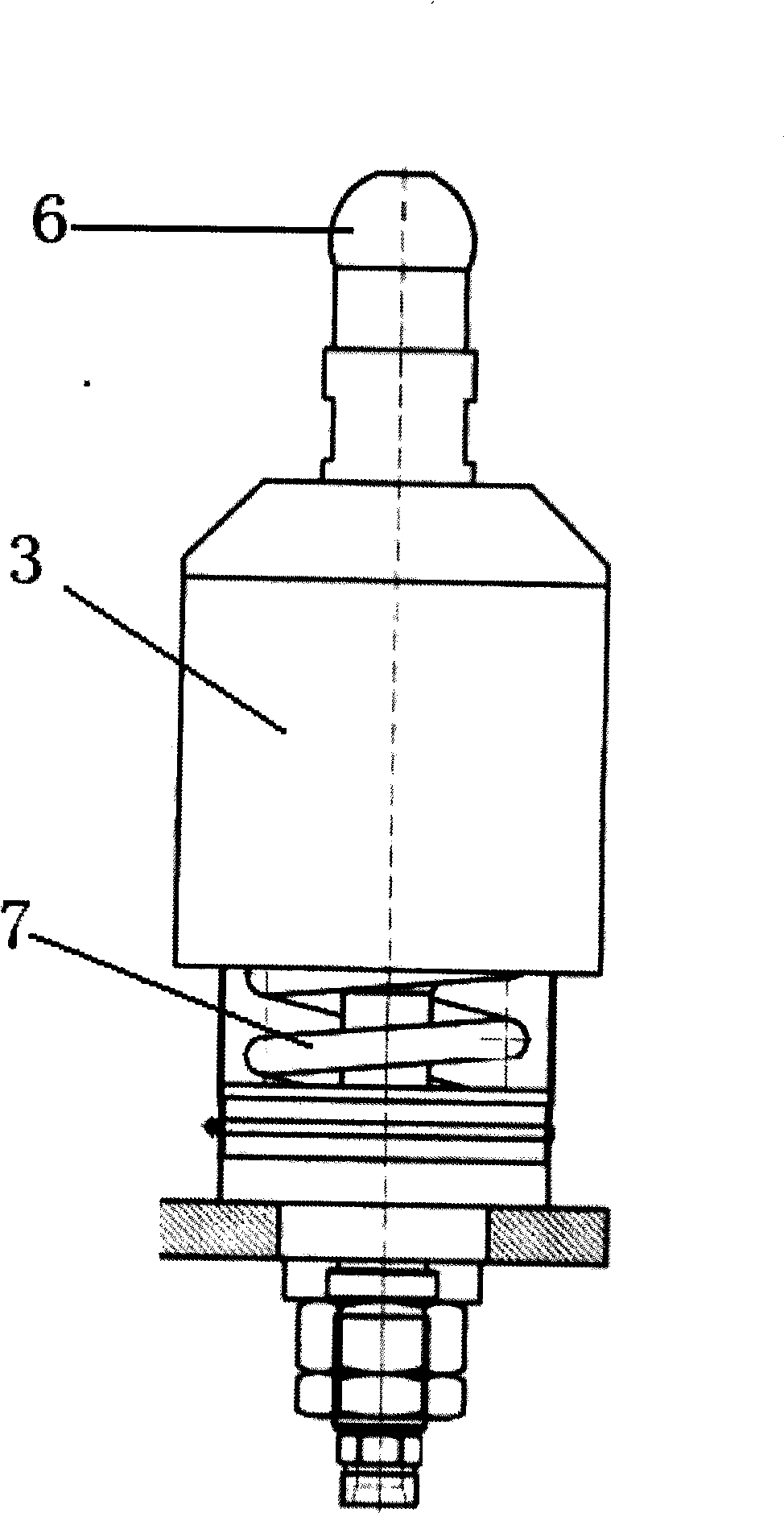

[0023] Such as Figure 1-4 As shown, the technical solution provided by the present invention is an argon blowing automatic connection mechanism used in the steelmaking process. The argon blowing automatic connection mechanism includes a pipeline 1, a ladle joint assembly 2 and a chartered car joint assembly 3. The ladle joint assembly 2 and the chartered car joint assembly 3 are automatically connected in the form of direct contact with the tapered surfaces. The ladle joint assembly 2 is installed on the ladle, and the ladle car joint assembly 3 is installed on the corresponding position of the ladle car. The corresponding position is convenient for the chartered car joint assembly 3 to automatically connect to the ladle joint assembly 2. When the ladle is hoisted on the ladle car, the ladle joint assembly 2 and the chartered car joint assembly 3 are automatically connected to form an argon automatic connection device. The ladle joint assembly 2 includes a bottom plate, a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com