Vacuum degasification system steam jet and last stage pressure air injection vacuum technology

An air injection and vacuum degassing technology, which is applied in the field of vacuum degassing systems in the metallurgical industry, can solve the problems of high maintenance and repair costs of water ring pump system equipment, increased power consumption of the system, and mechanical wear of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

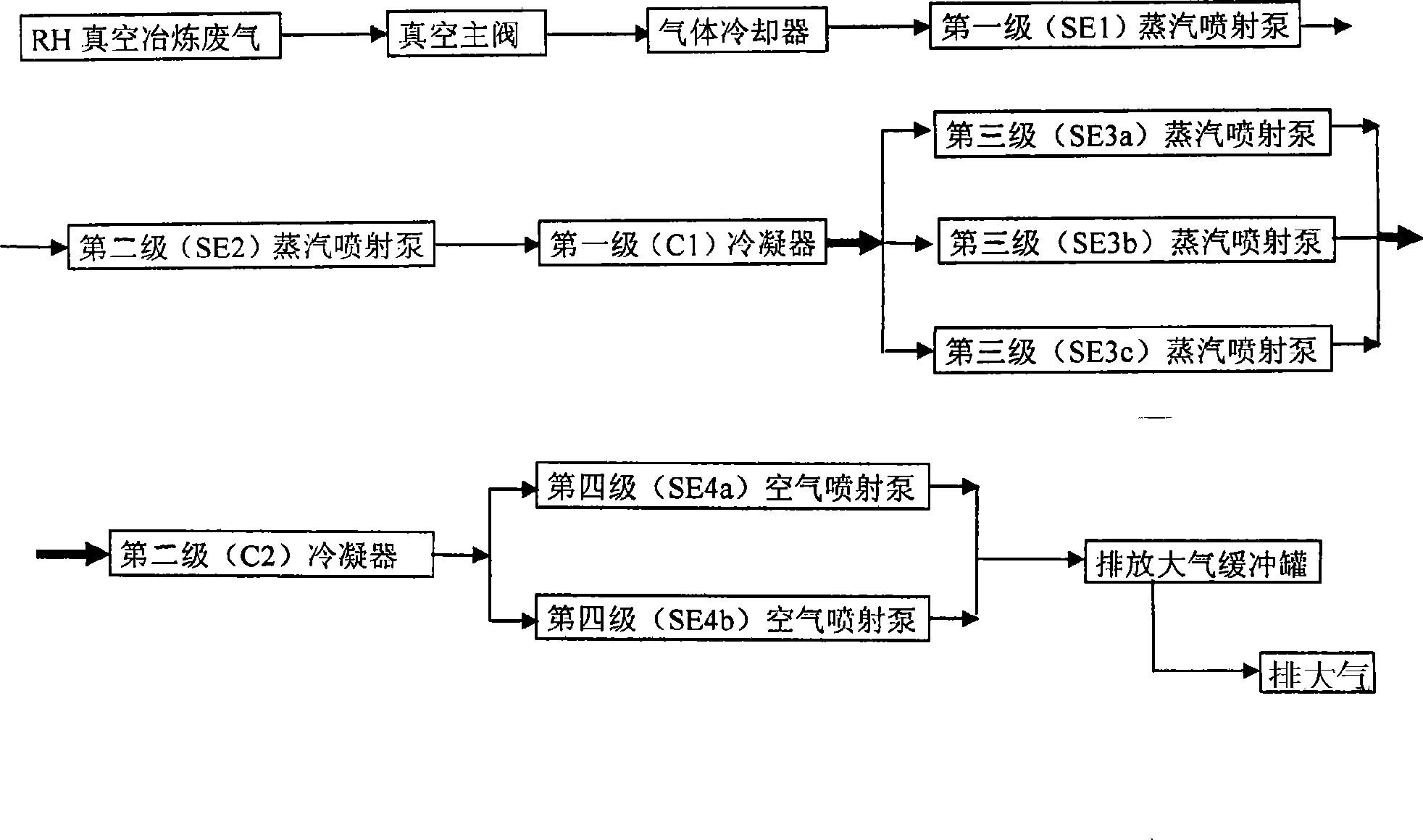

[0038] Referring to accompanying drawing, according to a kind of vacuum degassing system steam injection of the present invention adds the vacuum process of final stage pressure air injection, take following vacuum process flow:

[0039] Vacuum cycle degassing method RH vacuum smelting waste gas → vacuum main valve → gas cooler → first stage SE1 steam jet vacuum pump → second stage SE2 steam jet vacuum pump → first stage C1 condenser → third stage SE3a, SE3b, SE3c steam Jet vacuum pump → second stage C2 condenser, → fourth stage SE4a, SE4b pressure air jet vacuum pump → discharge atmosphere buffer tank → exhaust atmosphere.

[0040] 1. Vacuum circulation degassing method (RH) vacuum smelting waste gas: RH vacuum smelting is to discharge waste gas (H 2 , O 2 , N 2 and other harmful gases) to ensure the quality of finished steel. The purpose of installing a vacuum pump is to create a vacuum condition for vacuum smelting. In a vacuum state, the temperature of the dusty waste g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com