Combined steel sheet pile and integrated vertical wall used for bay dock or dock basin

A technology of combining steel sheet piles and steel sheet piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as unfavorable soil retaining, water stop, high engineering cost, and waste of materials, and achieve fast assembly speed and steel utilization. High efficiency and good overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

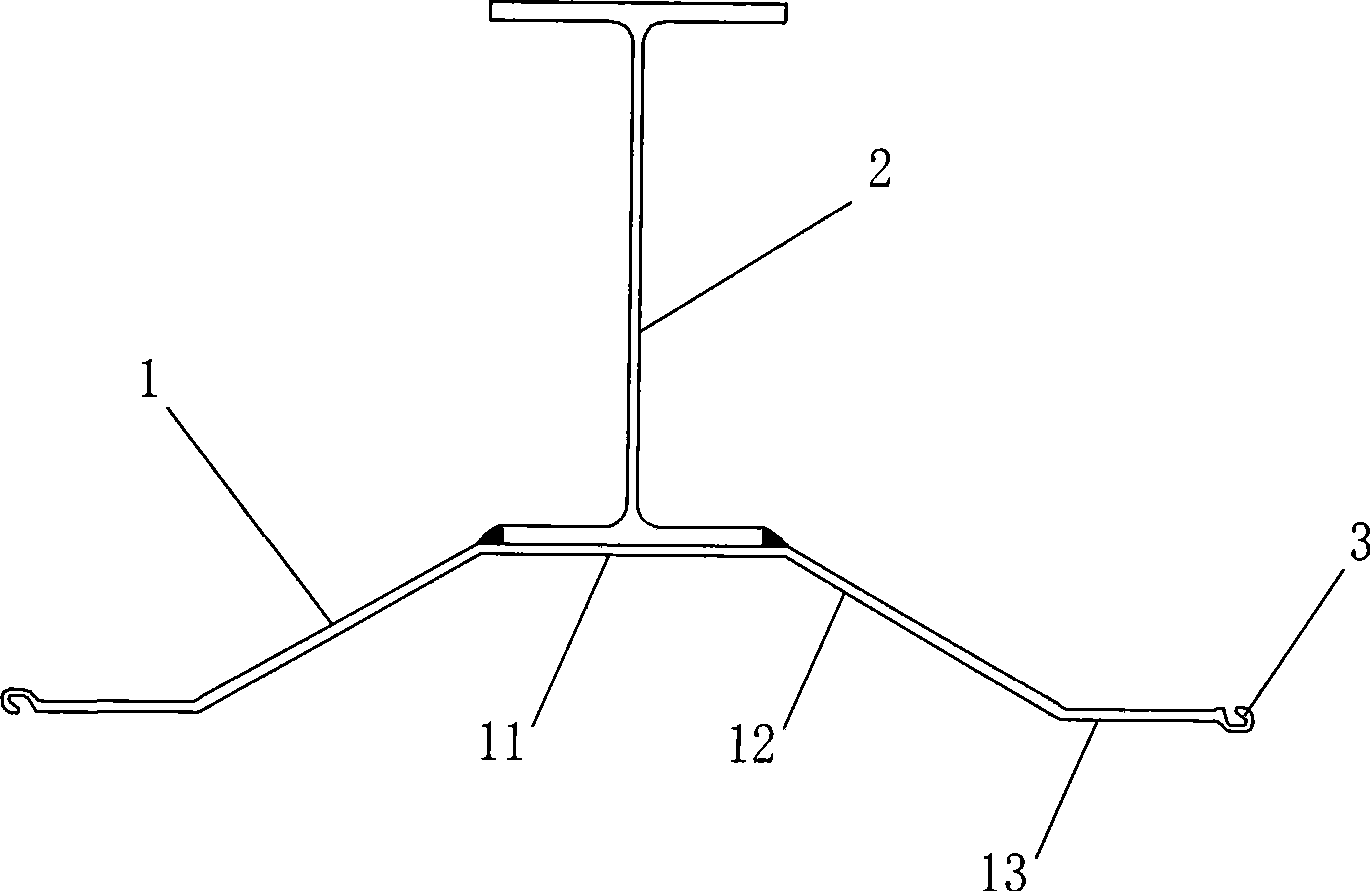

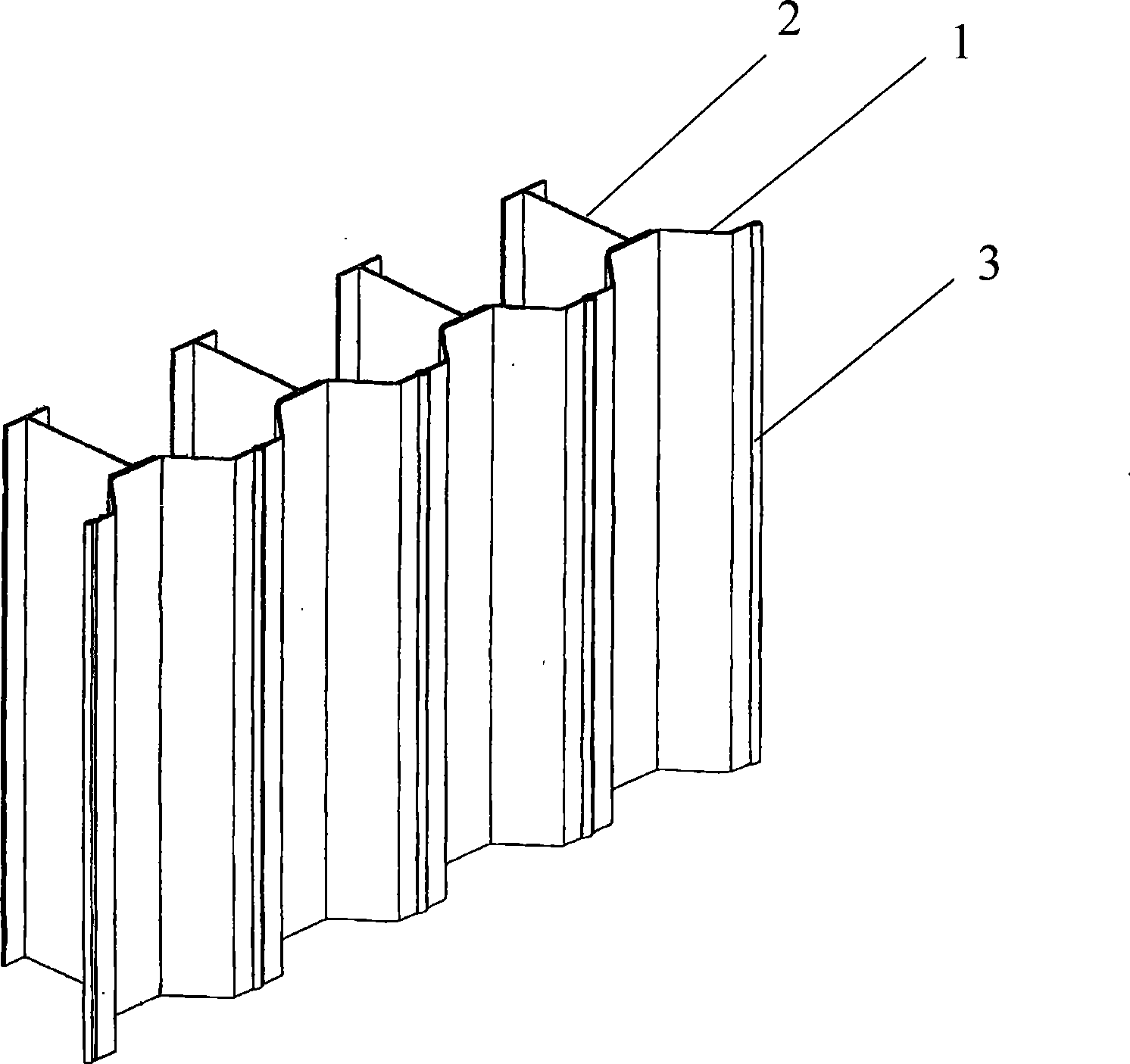

[0012] See attached figure 1 , the steel sheet pile 1 of the present invention is an imported wide-width "U"-shaped steel plate. The back 11 and the flanges 12 on both sides form a raised portion. On both sides of the raised portion, there are arm portions parallel to the web portion. 13. Two lock openings 3 are respectively provided at the ends of the two arms, which are arranged approximately in point symmetry with each other, so that more than two wide "U"-shaped steel sheet piles 1 can be connected through the mutual engagement of the locking openings on both sides. , the raised back of the wide "U"-shaped steel sheet pile 1 is provided with a domestic "H"-shaped steel 2, and the flange of the "H"-shaped steel 2 and the raised back of the "U"-shaped steel sheet pile 1 are fixed by welding or bolts The combined steel sheet pile with locking openings 3 on both sides can be welded by discontinuous welding or continuous surfacing welding.

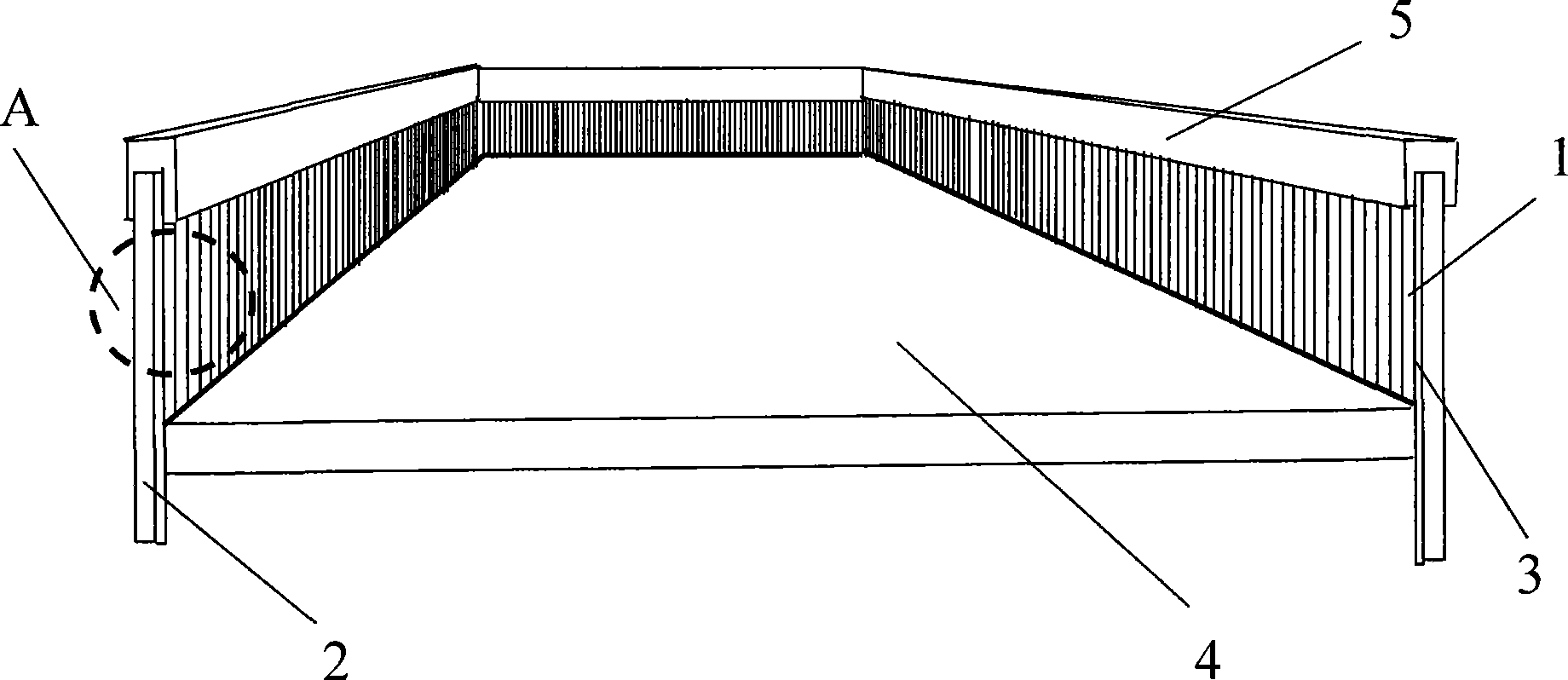

[0013] See attached figure 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com