Energy-saving horizontal multi-stage centrifugal pump

A centrifugal pump, horizontal technology, applied in the field of energy-saving horizontal multi-stage centrifugal pumps, can solve problems such as high energy consumption, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

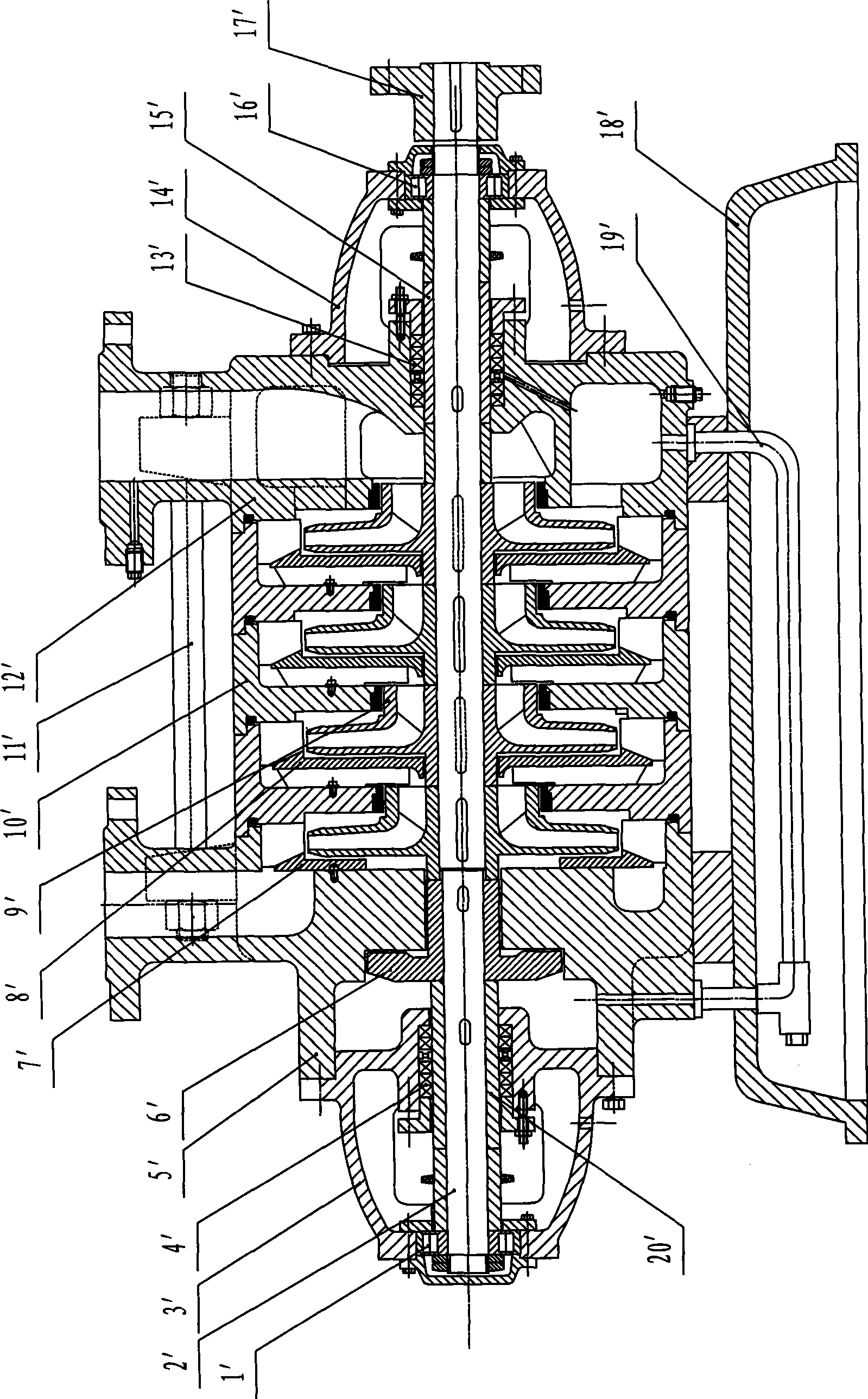

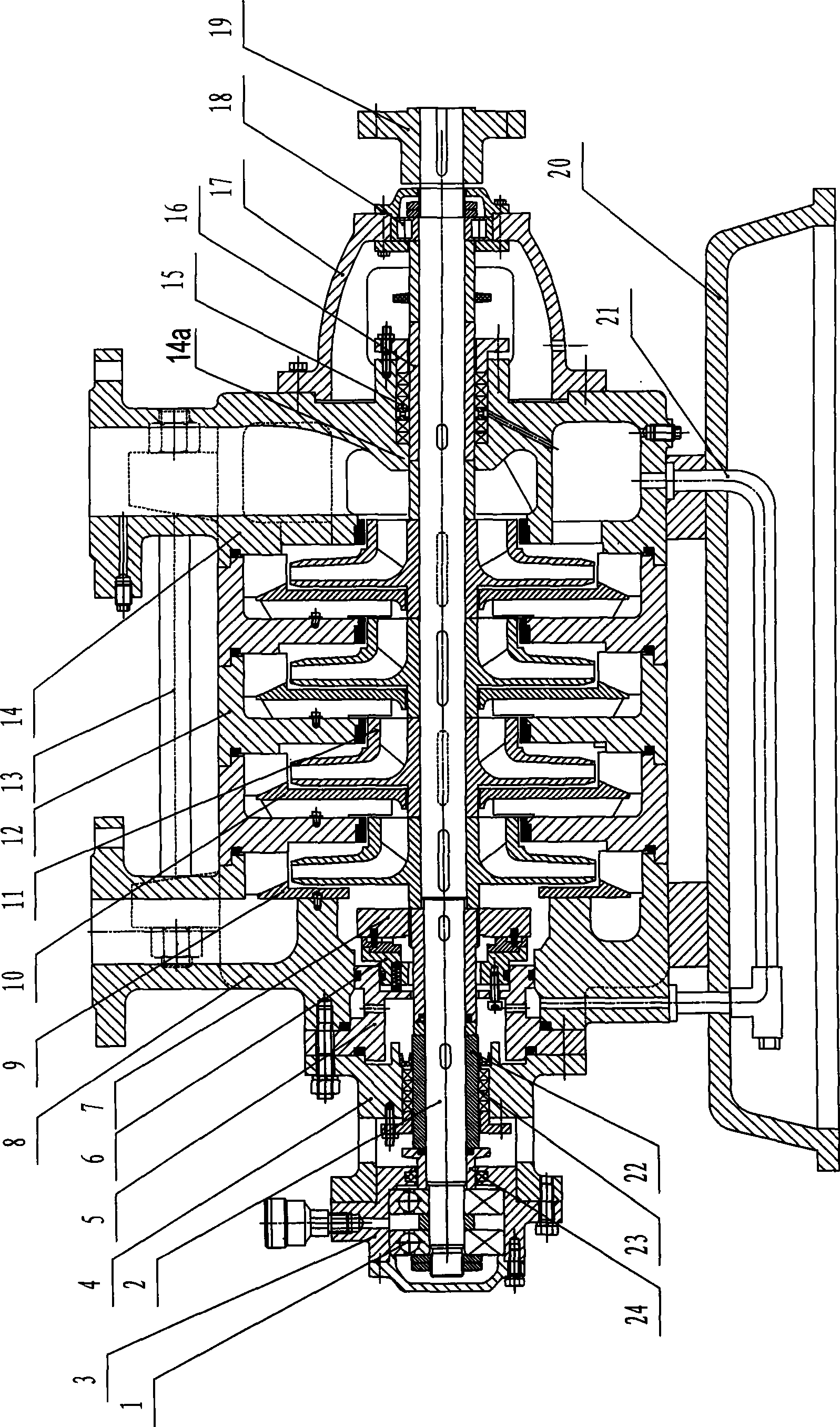

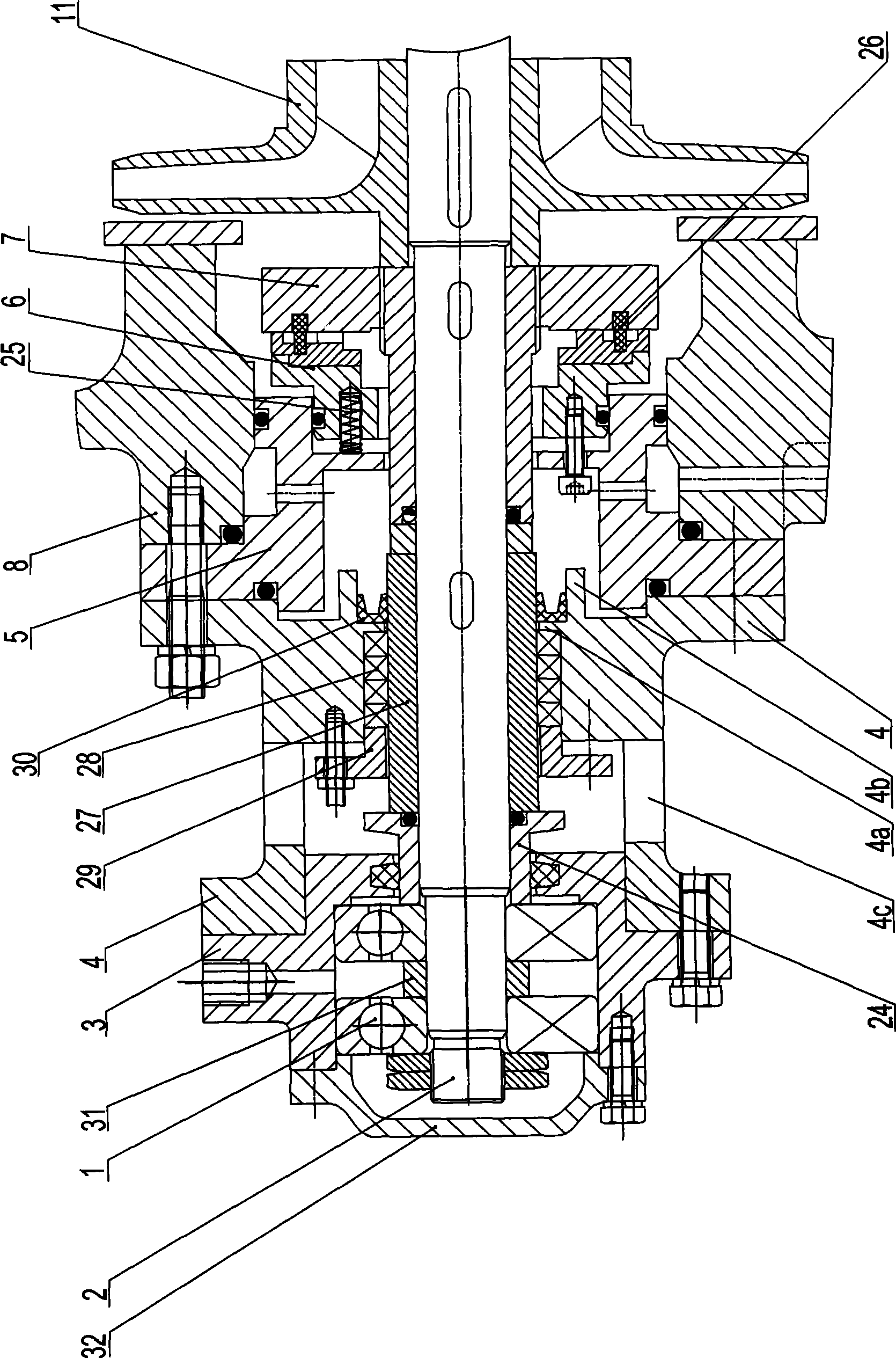

[0015] As shown in the figure: the water outlet casing 8 and the water inlet casing 14 are arranged at intervals on the base 20, and there is a middle casing 12 between the water outlet casing 8 and the water inlet casing 14, and the two bolts 13 are tightened. The ends are respectively arranged on the water outlet shell 8 and the water inlet shell 14, and the water outlet shell 8, the middle shell 12 and the water inlet shell 14 are compressed to form a pump cavity, and the water outlet shell 8 and the water inlet The pump shaft 2 is arranged on the horizontal rotatable frame on the casing 14 of the water section, the impeller 11 and the guide vane 10 are arranged on the pump shaft 2 in the pump chamber, and there is a pump tail sealing device between the casing 14 of the water inlet section and the pump shaft 2, A return pipe 21 is provided on the water outlet casing 8 and the water inlet casing 14, and a disc-shaped pump end seal 4 is fixed on the water outlet casing 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com