Multi-splitting bus

A multi-split, busbar technology, applied in the direction of a rod/rod/line/strip conductor, etc., can solve the problems of low current carrying capacity, inability to melt ice and snow, and many consumables, etc. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

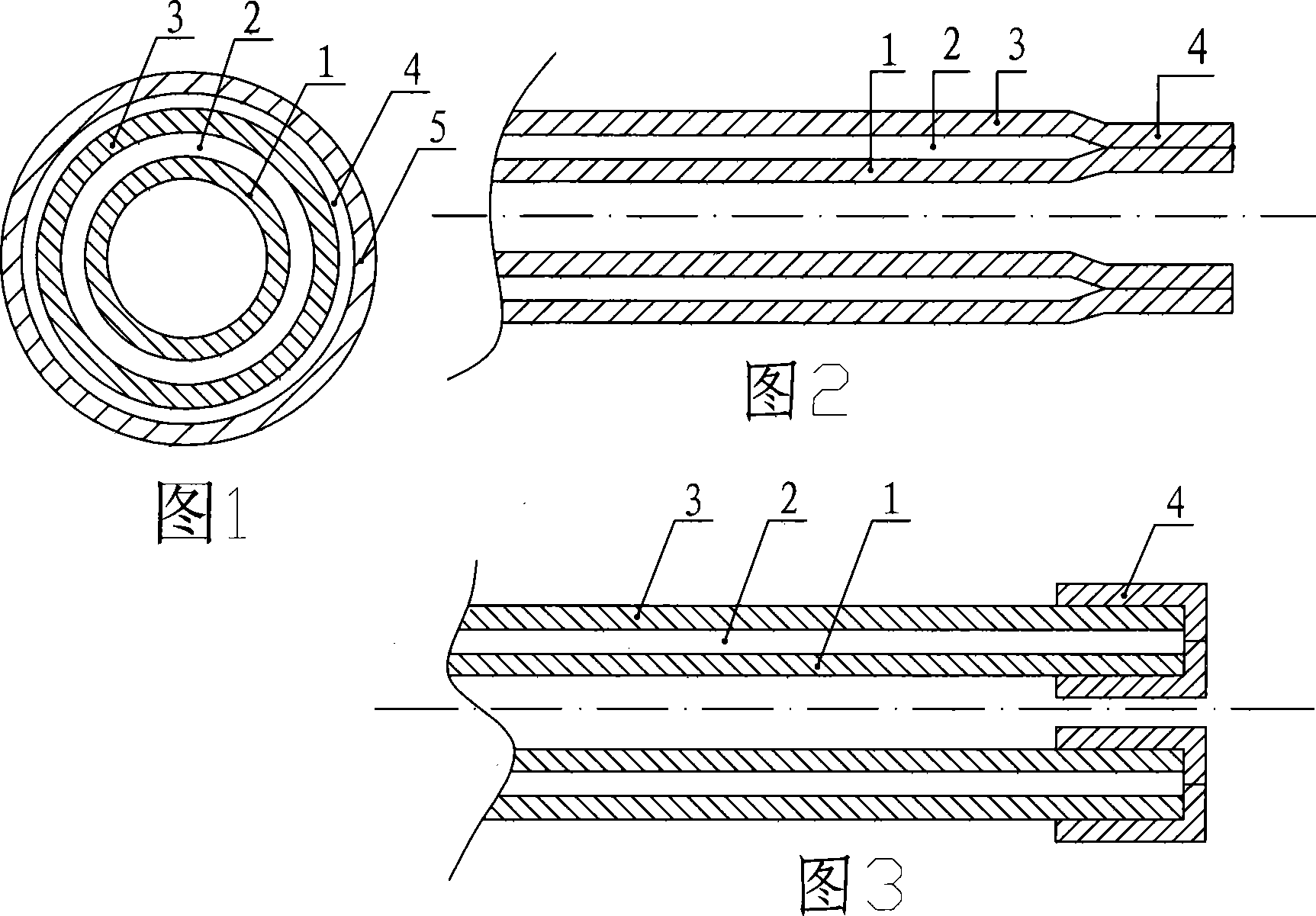

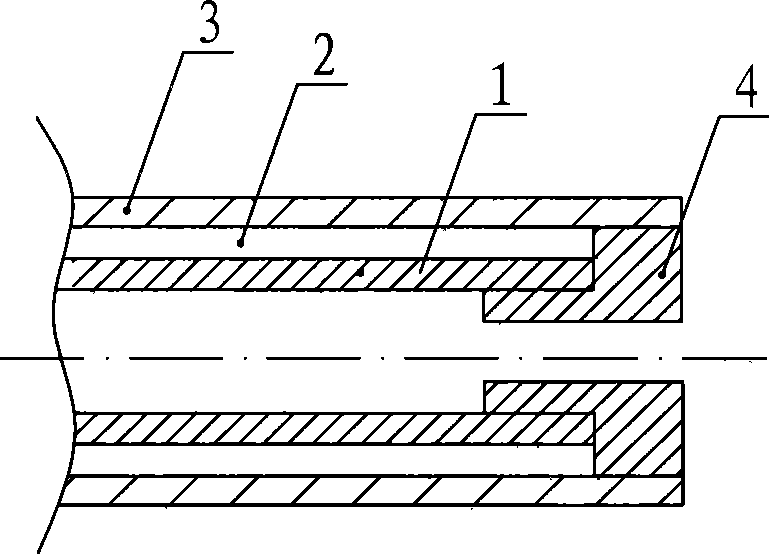

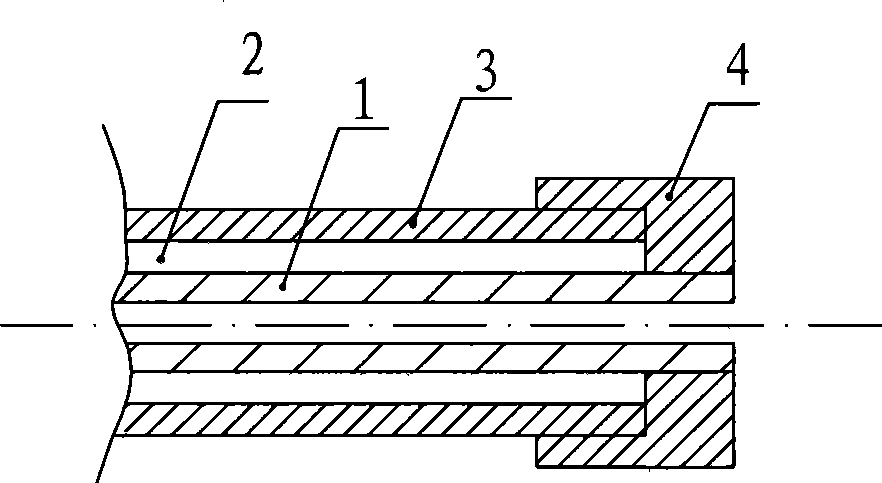

[0059] 1.——As shown in Figure 1, a multi-split busbar composed of multi-layer conductive tubes (such as a large conductive tube directly covering a small conductive tube), there is an insulating layer between the conductors, and each conductor has two conductive surfaces.

[0060] Example: ①The rated current is 3150A, the wall thickness of the copper tube bus conductor is 3mm, and it is composed of two layers of 1.5mm conductors. There is an insulating layer between the conductors and the conductors. , diameter 100mm, cross-sectional area 914mm 2 , weight 8.1kg per meter, current density: 3.4(A / mm 2 ), temperature rise 40k.

[0061] The manufacturing method of the multi-split bus bar (tube shape) composed of multi-layer conductive tubes: according to the current carrying capacity requirements, select the appropriate thin copper or aluminum plate (thickness 0.1mm ~ 20mm), use the welded tube production line to produce copper or aluminum tubes first, and then Insulation treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com