Bushing for production of glass continuous filament, equipment for producing glass continuous filament and process for production of the filament using the equipment

A glass fiber and manufacturing method technology, applied in the field of improvement of outer surface properties, can solve problems such as the influence of various factors such as temperature and speed or atmosphere in dimension, and achieve the effect of economical cheapness and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

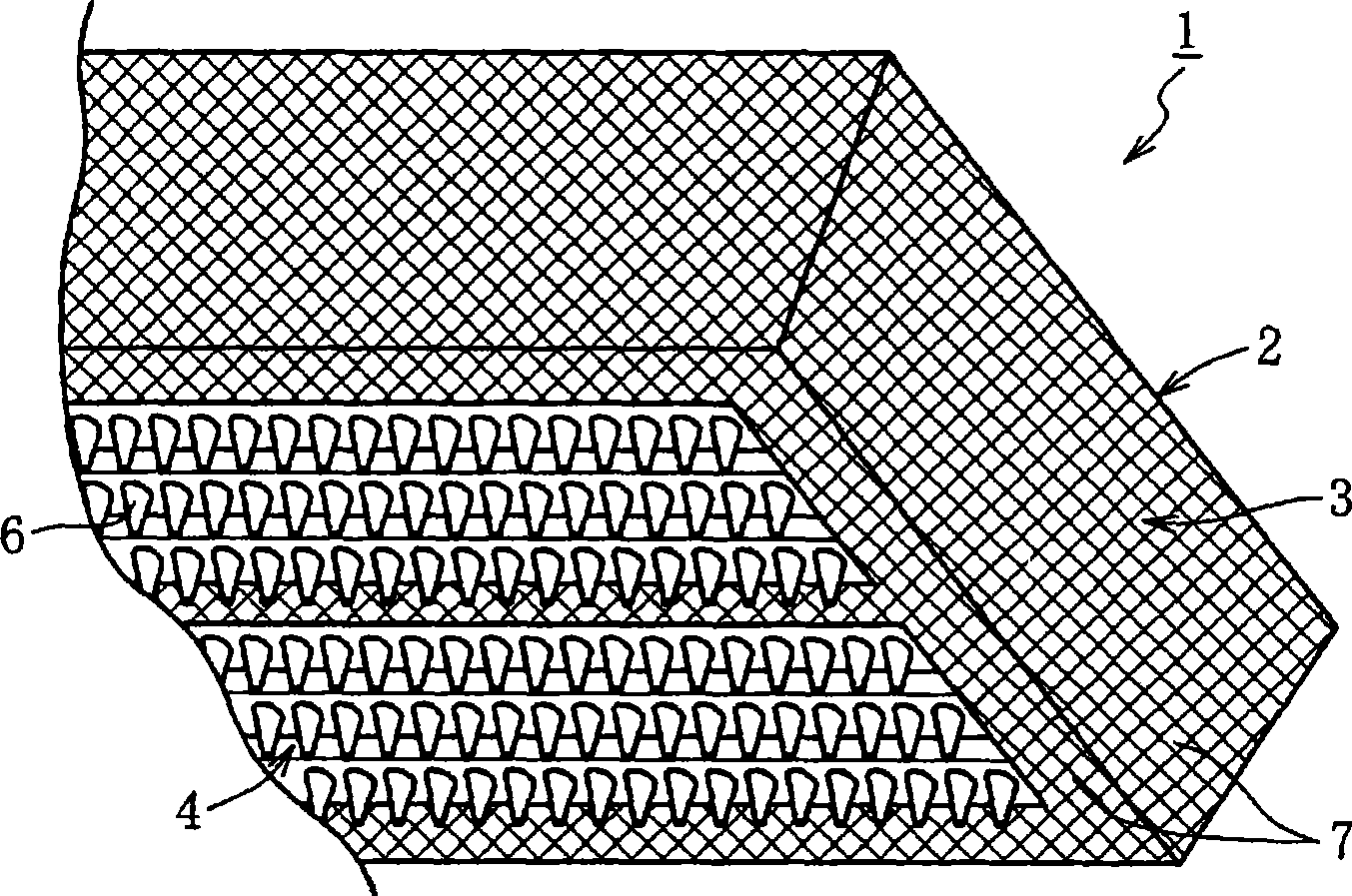

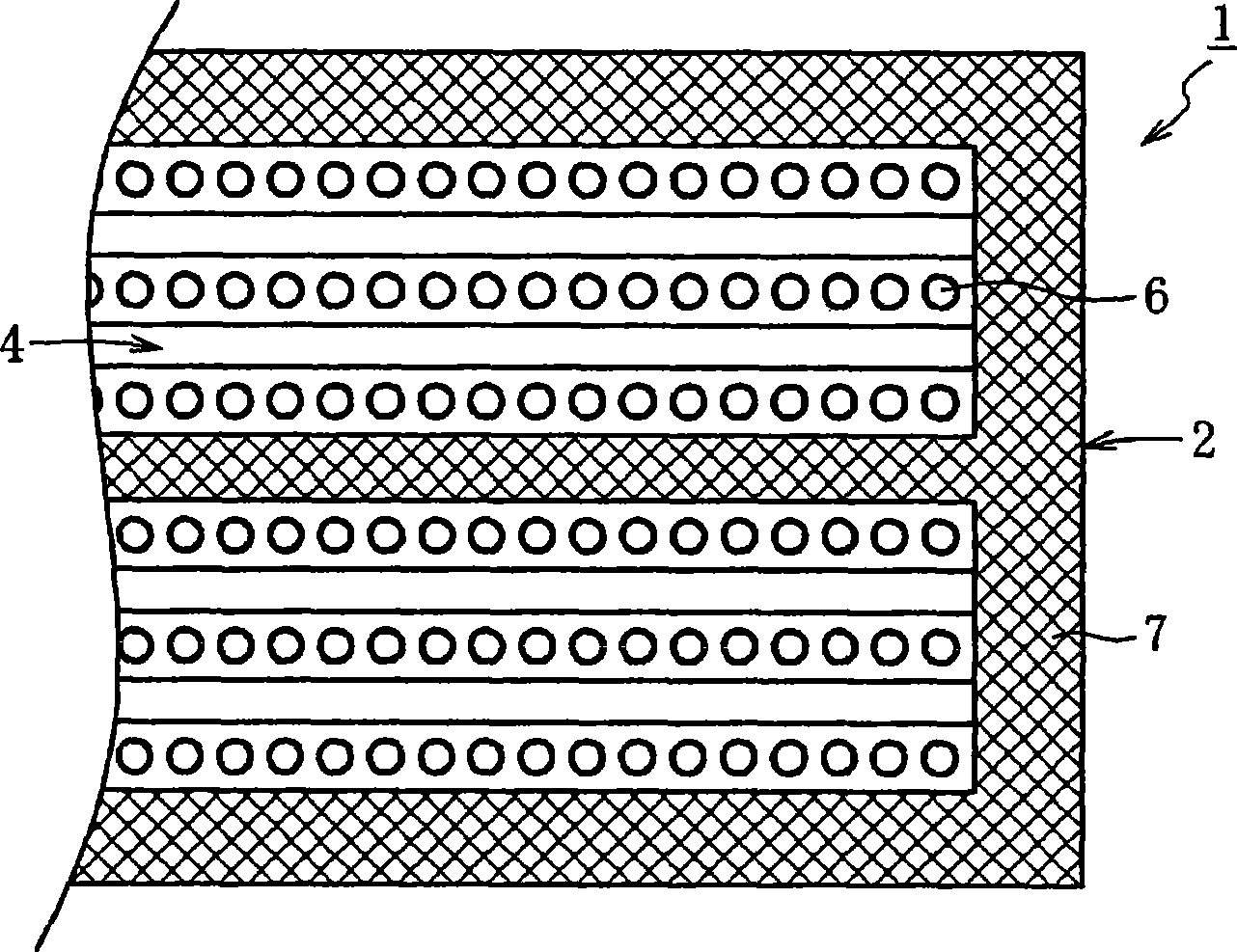

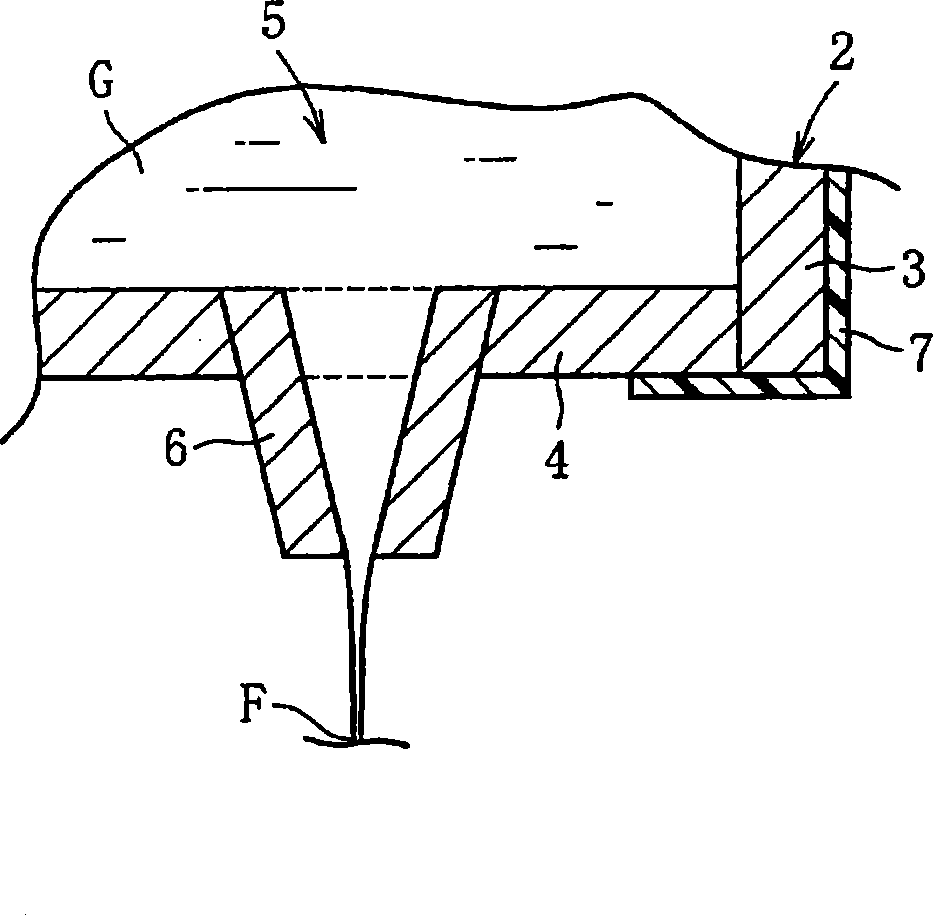

[0081] Next, the bushing for continuous glass fiber production (hereinafter, simply referred to as "tank") of the present invention will be described with reference to the drawings.

[0082] Figure 1 ~ Figure 3 It is a figure which shows the bushing 1 with which the continuous glass fiber manufacturing apparatus is equipped, figure 1 is a perspective view showing the main part of the bushing 1, figure 2is a plan view showing the main part of the bushing plate 1, image 3 It is an enlarged longitudinal sectional front view showing only the nozzle periphery of the bushing 1 . Such as figure 1 and figure 2 As shown, the bushing 1 is a bushing used when forming continuous glass fibers (or spinning) made of E glass for FRP. And the bushing plate main body 2 of this bushing plate 1 is fixed with the bushing plate 4 at the bottom of the bushing plate peripheral wall portion 3 and is constituted, and its interior is a molten glass supply space 5 (refer to image 3 ). Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com