Novel power supplying system using electric railway direct feeding system of outdoor modularized electric device

A technology for electrified railways and power supply, applied in power lines, overhead lines, transportation and packaging, etc., can solve the problems of high investment cost, troublesome maintenance, large floor space, etc., achieve high degree of factory manufacturing and short construction period , the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings.

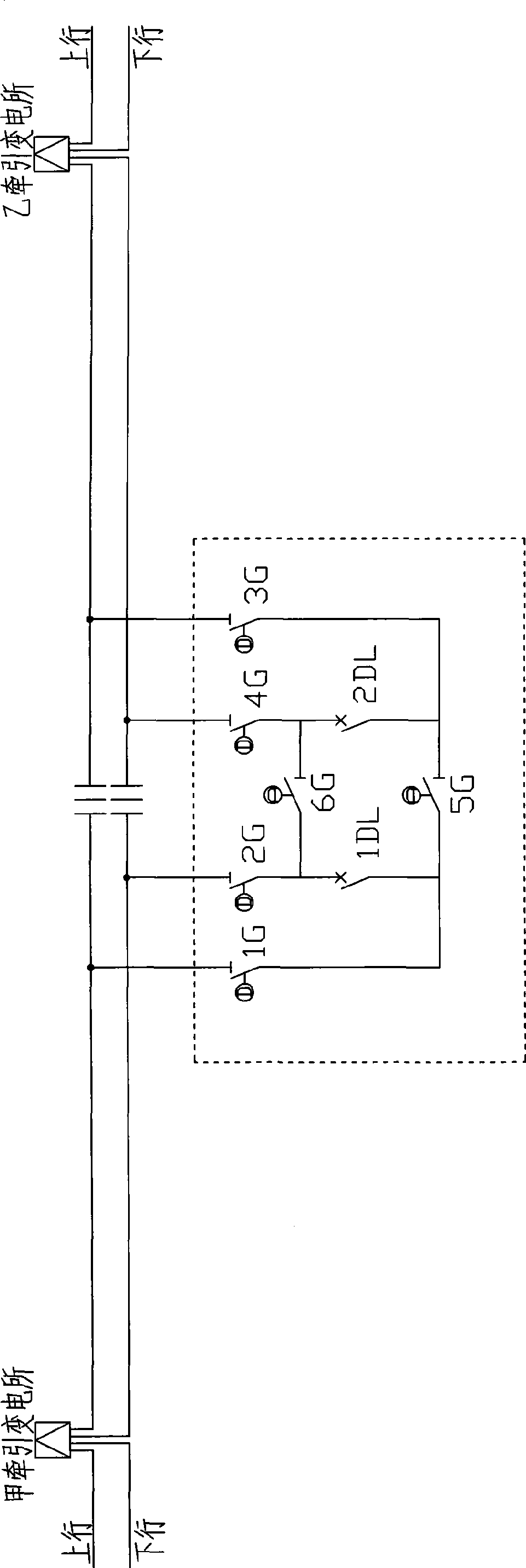

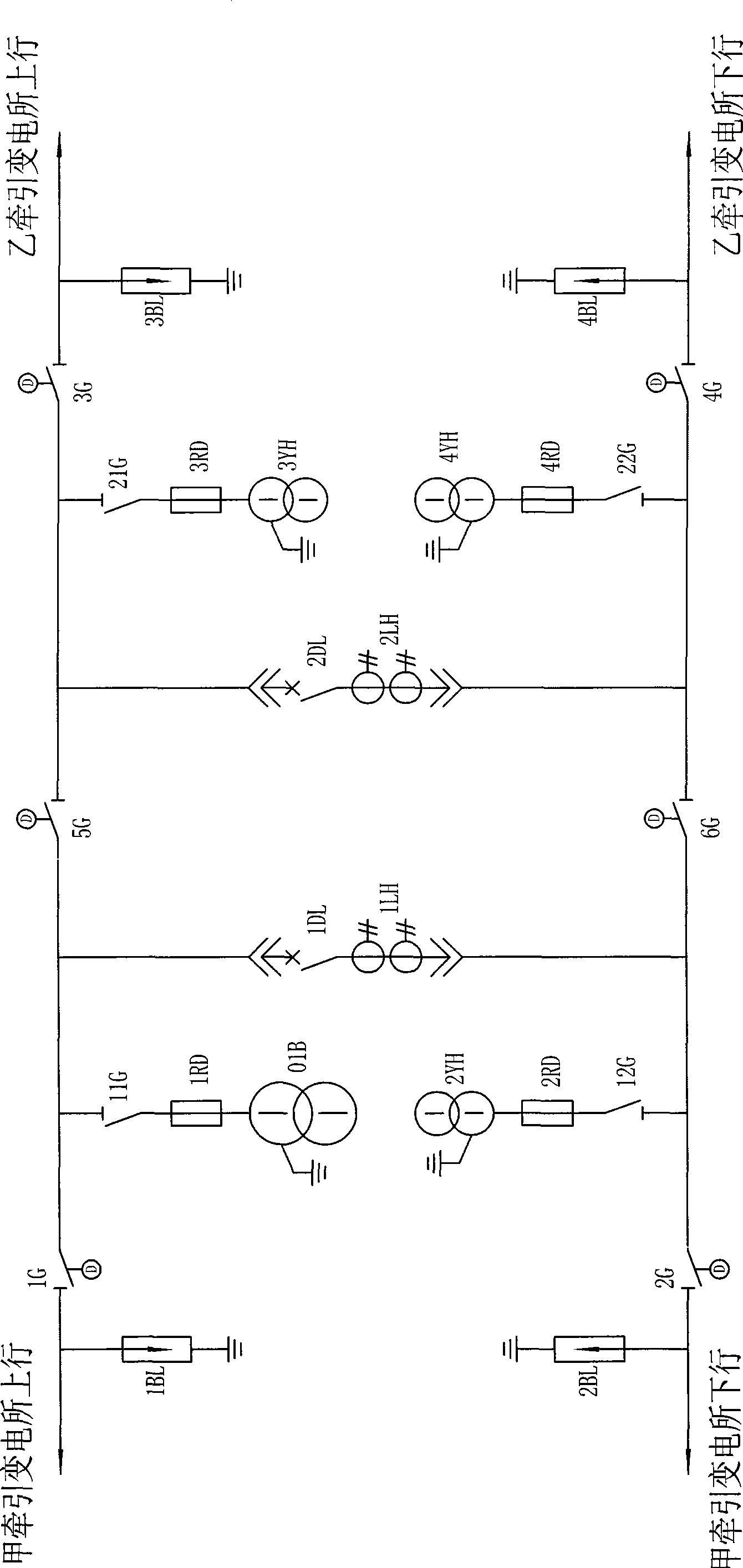

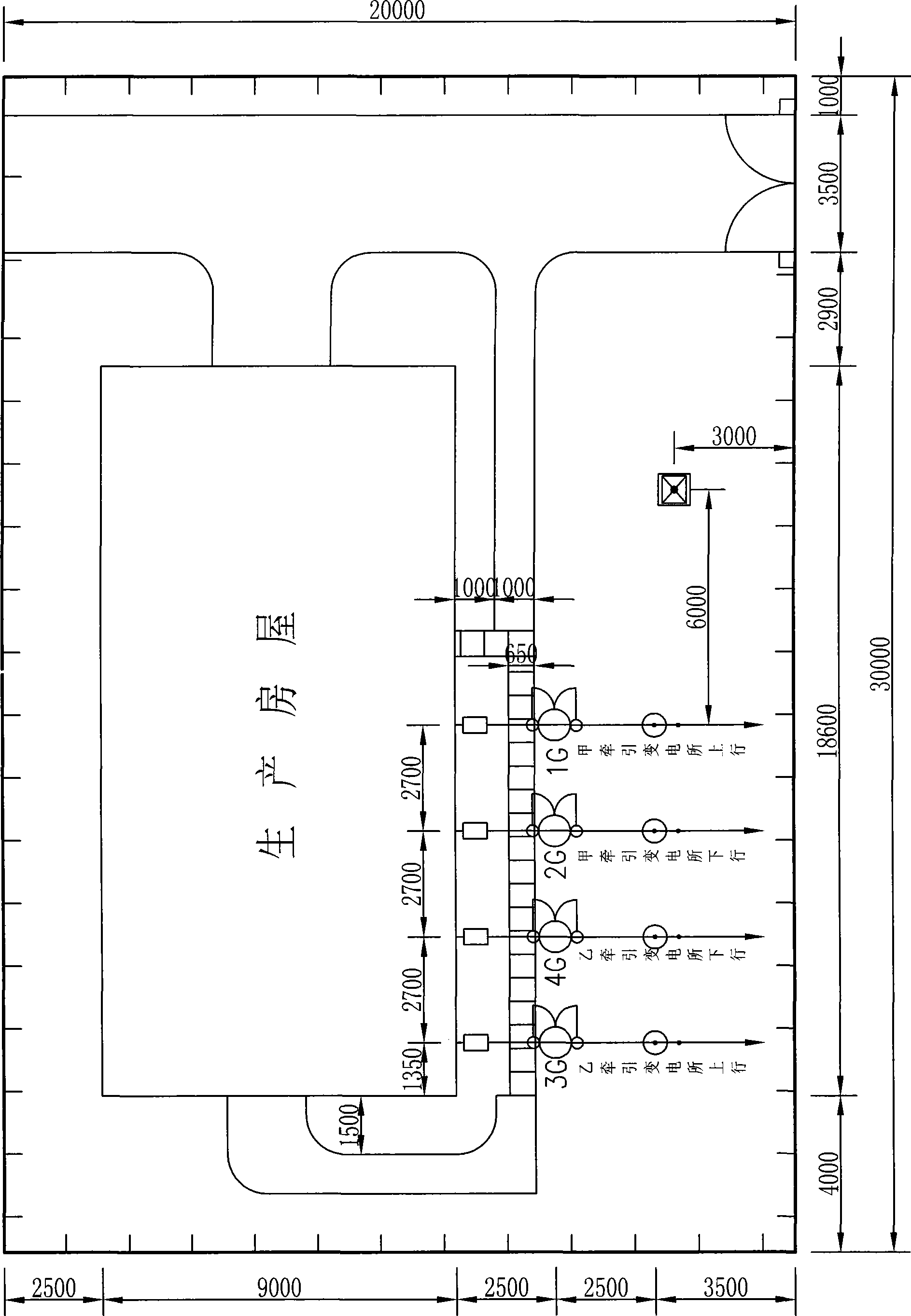

[0073] refer to Figure 8 ~ Figure 13, a new type of power supply system for electrified railway direct power supply using outdoor modular appliances, including a traction substation arranged on the side of the electrified railway, the output side of the traction substation is connected to the up / down catenary, and the Parallel equipment with parallel power supply function is provided between the power supply arm ends of the up / down catenary of two adjacent traction substations, and at the power supply arm ends of the up / down catenary of two adjacent traction substations There are over-area equipment with over-area power supply function in the sub-phase, and switching equipment with segmented or partitioned power supply functions are arranged between the up / down catenary and the feeder end. The up / down catenary passes through two The power connection isolating switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com