Tension control system

A technology of tension control and tension, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of no visual display of tension values, different tension values at transmission points, and broken main drive shafts, etc., to achieve automation The degree of stability and reliability, reliable performance, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

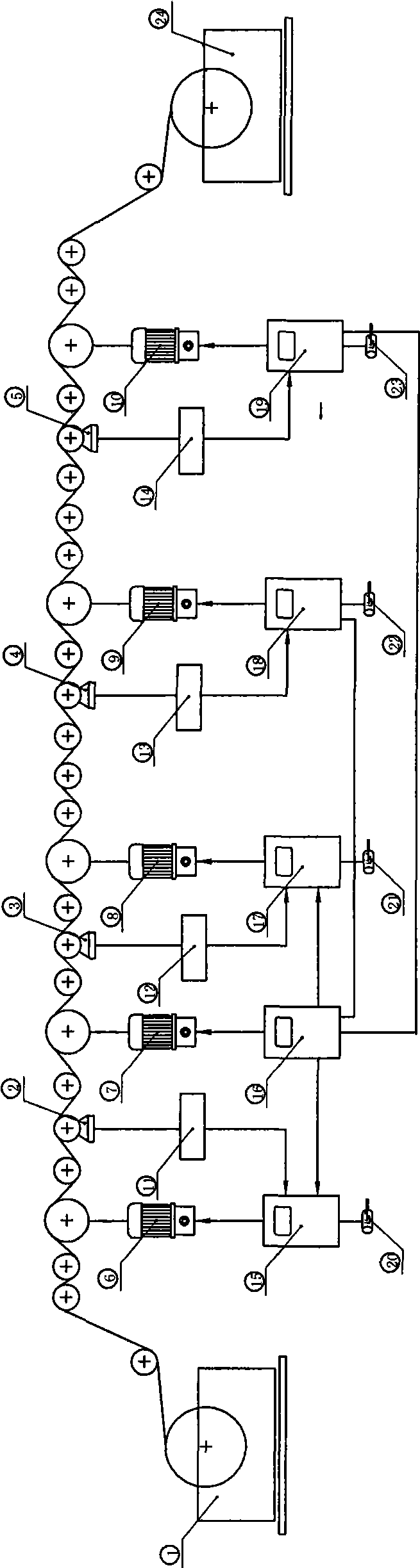

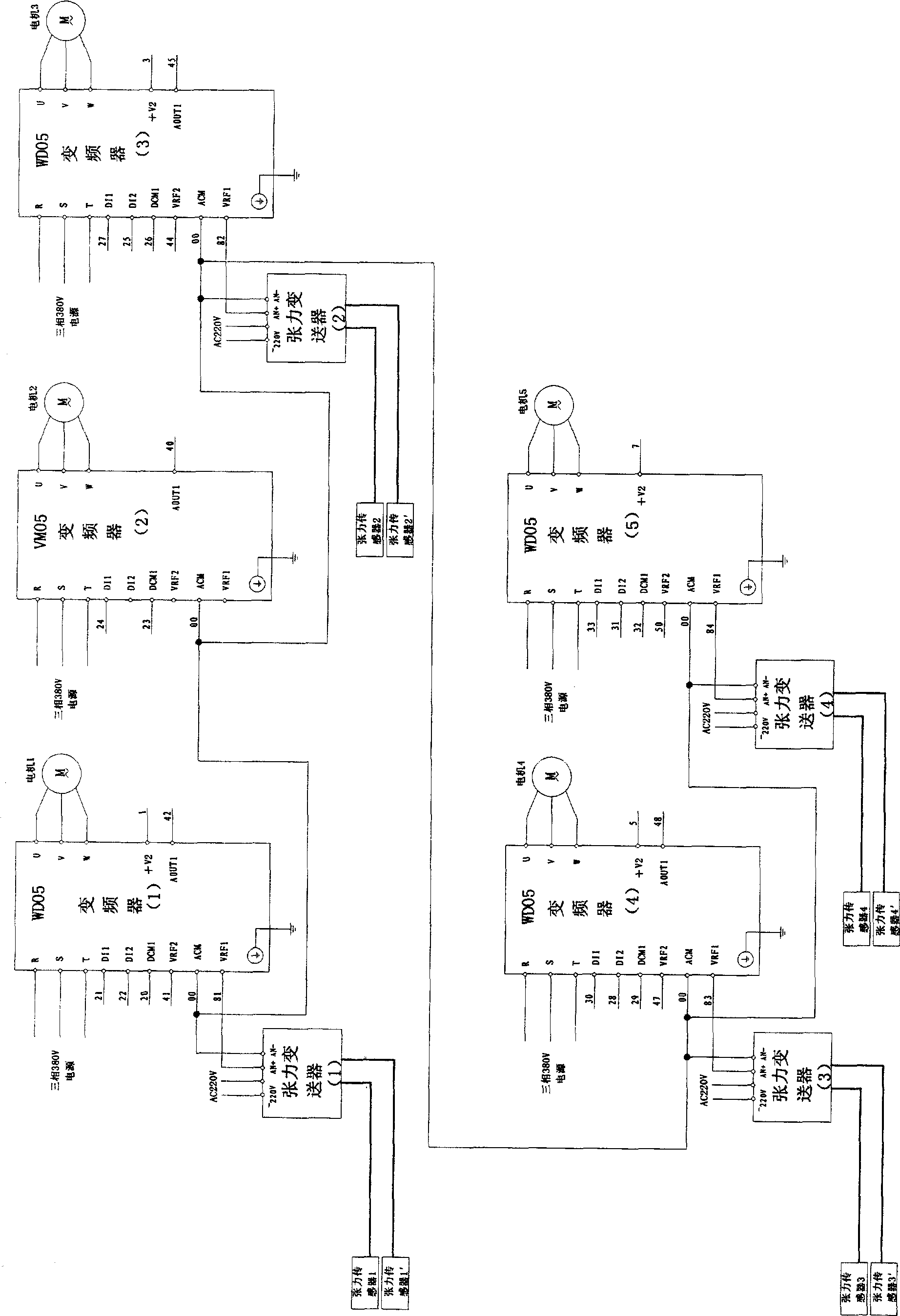

[0019] refer to figure 1 , except that the present invention has a copper conductive roller each in the foil releasing device 1 and the foil receiving device 24, 27 rollers are also arranged at various positions of the entire walking foil, wherein five driving rollers are respectively arranged on the 4th, 8th, 4th, 8th, The positions of 12, 18, and 24 are copper rollers, and the remaining 22 rollers are PP rollers, the driving roller is a copper roller, the driven roller is a PP roller, and the driving roller and the driven roller are connected by sprockets. Four tension sensors 2, 3, 4, and 5 are placed on driven rollers 6, 10, 16, and 22, and the tail ends of the five driving rollers are respectively connected to three-phase asynchronous motors + reducer kits 6, 7, and 8 , 9, 10, four transmitters 11, 12, 13, 14 are connected to four tension sensors 2, 3, 4, 5, four transmitters 11, 12, 13, 14 and four sets of three-phase Motor+reducer kits 6, 8, 9, and 10 are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com