Hypocycloid single cylinder diesel

A hypocycloid and diesel engine technology, applied in the direction of mechanical equipment, machine/engine, inertial force compensation, etc., can solve the problems of endangering the service life and reliability of internal combustion engines, affecting the economy and power of internal combustion engines, and increasing the difficulty of piston manufacturing, etc. , to achieve the effect of reducing vibration and noise, eliminating beating, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

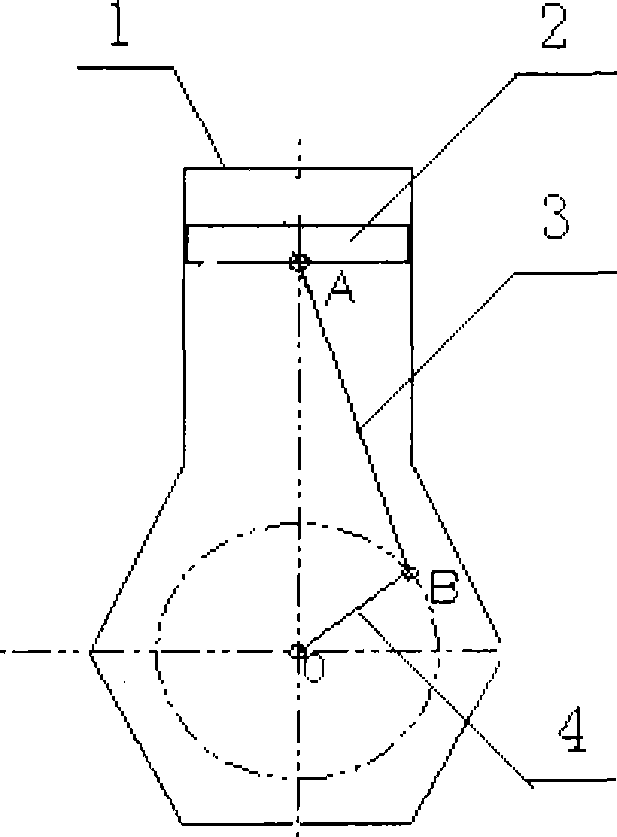

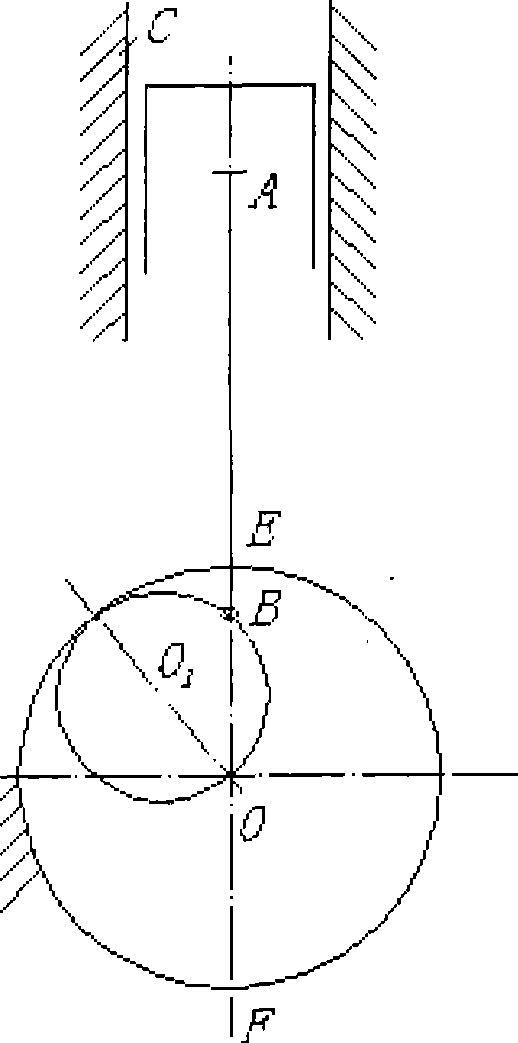

[0033] To transform the popular traditional piston diesel engine: the hypocycloidal energy conversion mechanism replaces the traditional crank connecting rod mechanism.

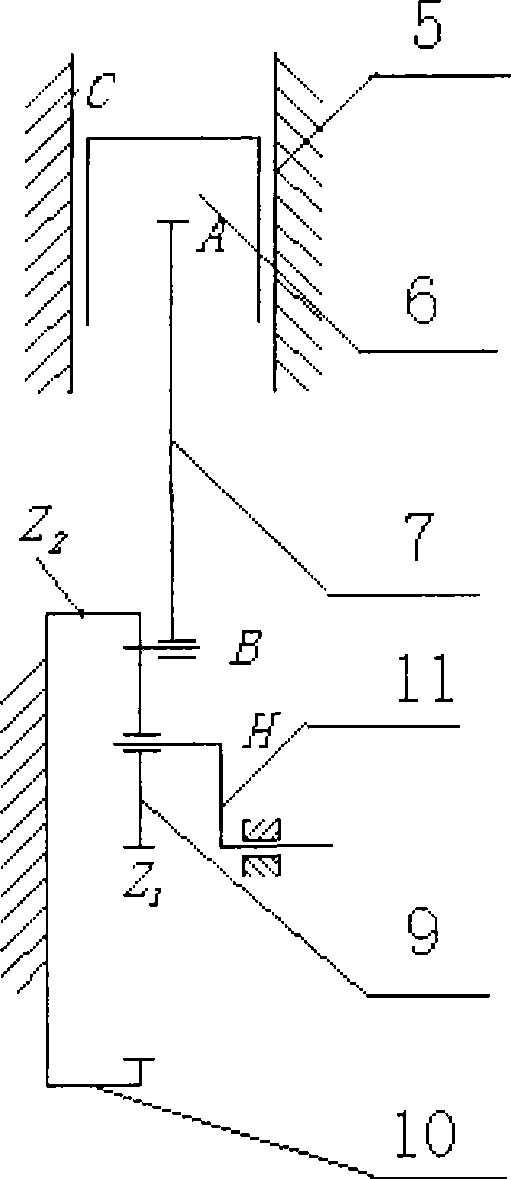

[0034] Such as image 3 , 4 As shown; according to the balance piston reciprocating inertial force of the eccentric dual-axis mechanism, the size of the balance shaft 14 is adjusted to meet the requirements of the balance piston reciprocating inertial force, and the shape and installation size of the box body 5 and the piston 6 can remain unchanged. Put the left crankshaft 8 and the right crankshaft 11 into the left and right bearings of the original crankshaft in the casing 5 respectively to ensure firm and stable operation. Will Figure 6The ring gear 10 shown is fixed on the lower part of the case body 5 by means of bolts and positioning pins. The left crankshaft 8 and the right crankshaft 11 are respectively connected with the middle eccentric crankshaft 13 through two sliding bearings 17 to form a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com