Supercritical DC furnace synthesis type coordinating control method

A supercritical direct current furnace and coordinated control technology, which is applied in the direction of control system, steam generation, lighting and heating equipment, etc., to achieve the effect of improving dynamic response ability, improving control effect and improving control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

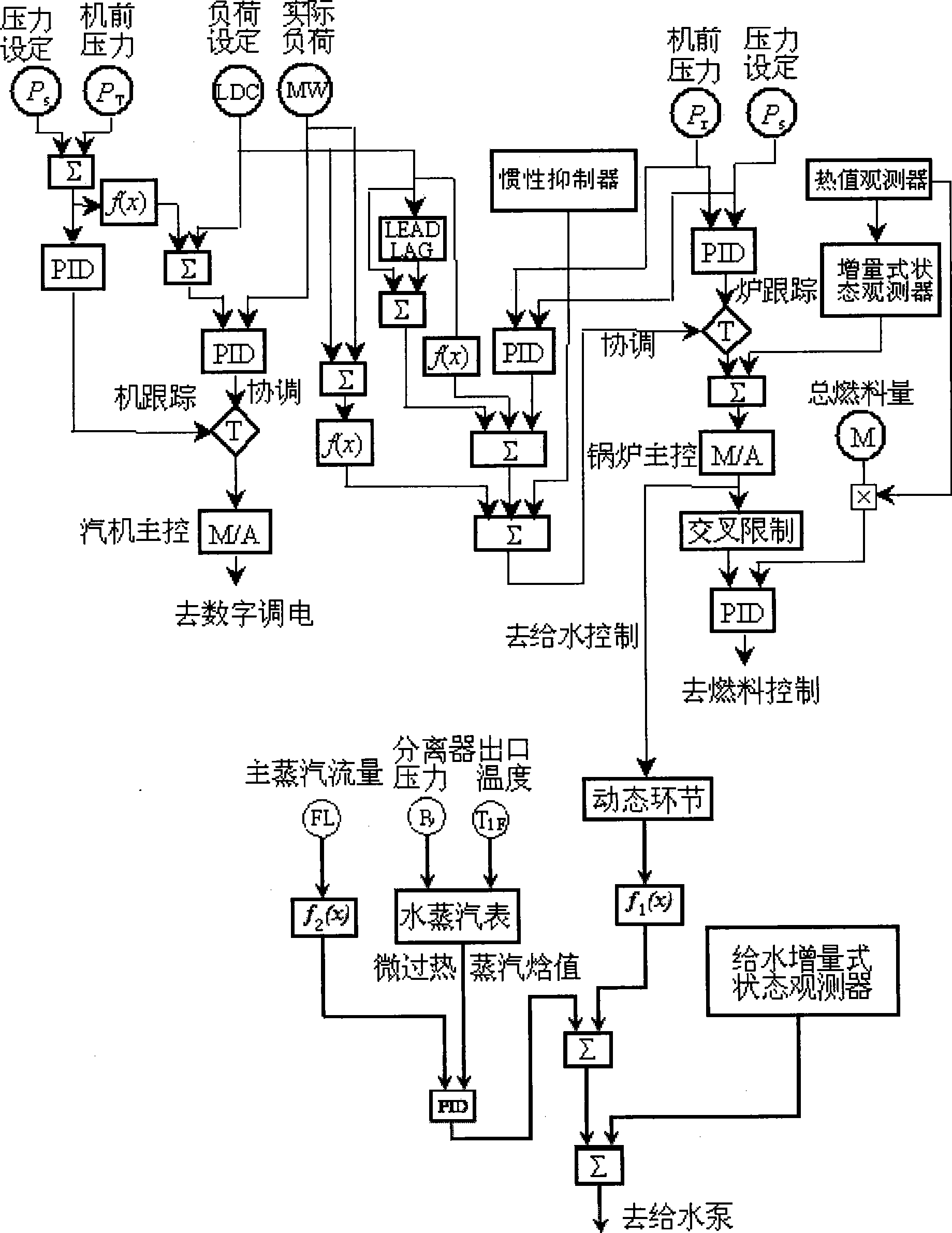

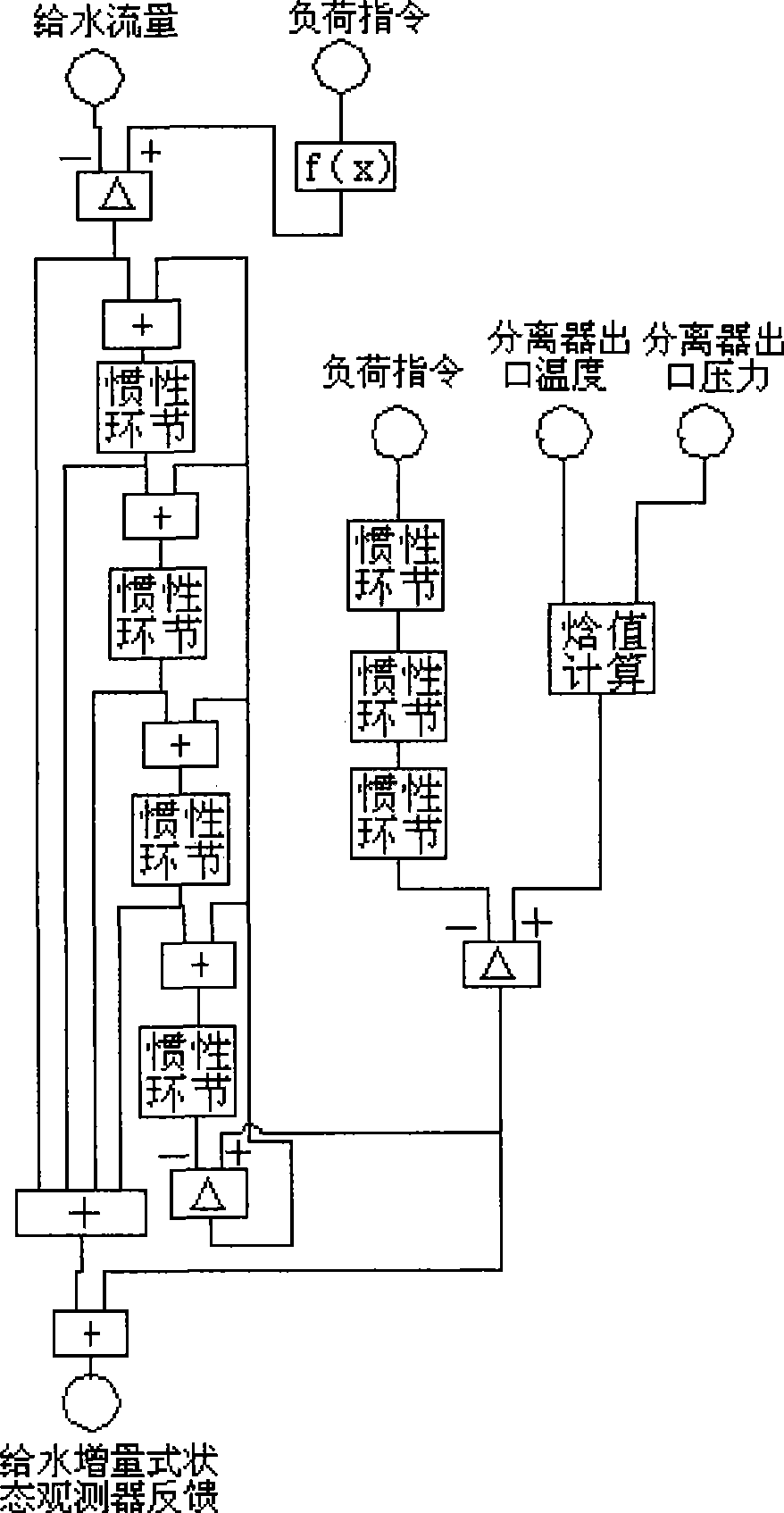

[0013] Such as figure 1 As shown, the basic idea of the present invention is: in the traditional coordinated control system, an incremental state observer and an inertial suppressor are added as the feedforward of the combustion rate control, and an incremental state observer of the water supply is added as the feedforward control of the water supply. Feedforward, used to improve the dynamic effect of feedwater control. For the supercritical DC furnace, since a certain amount of heat needs to correspond to a certain amount of water, a calorific value observer is added to the calorific value calculation loop of the traditional coordinated control system, and the observer corrects the heat signal of coal combustion in real time.

[0014] Based on above basic idea, method of the present invention comprises the following steps:

[0015] 1. Carry out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com