Uniaxial air bearing table balance adjustment method

A technology of balance adjustment and air flotation table, applied in the field of measurement, can solve problems such as difficult engineering applications and no implementation methods given, and achieve the effect of no electromagnetic interference, low cost, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

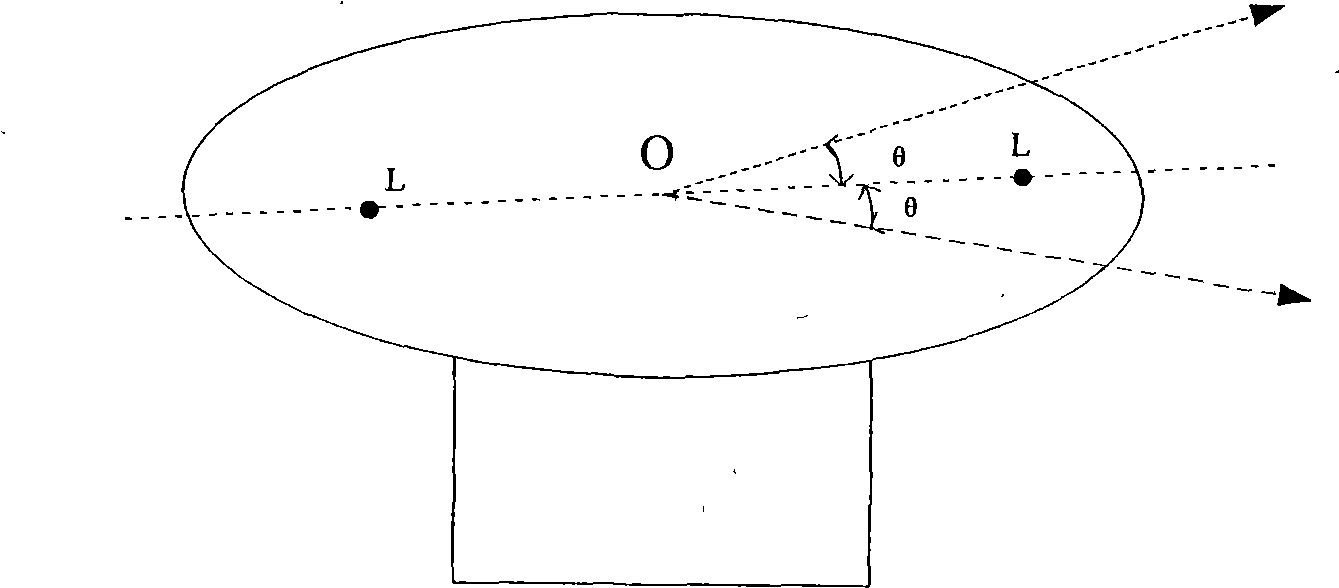

[0017] Embodiment 1, combining figure 1 , figure 2 , the method for adjusting the balance of the uniaxial air bearing platform of the present invention, the steps are as follows:

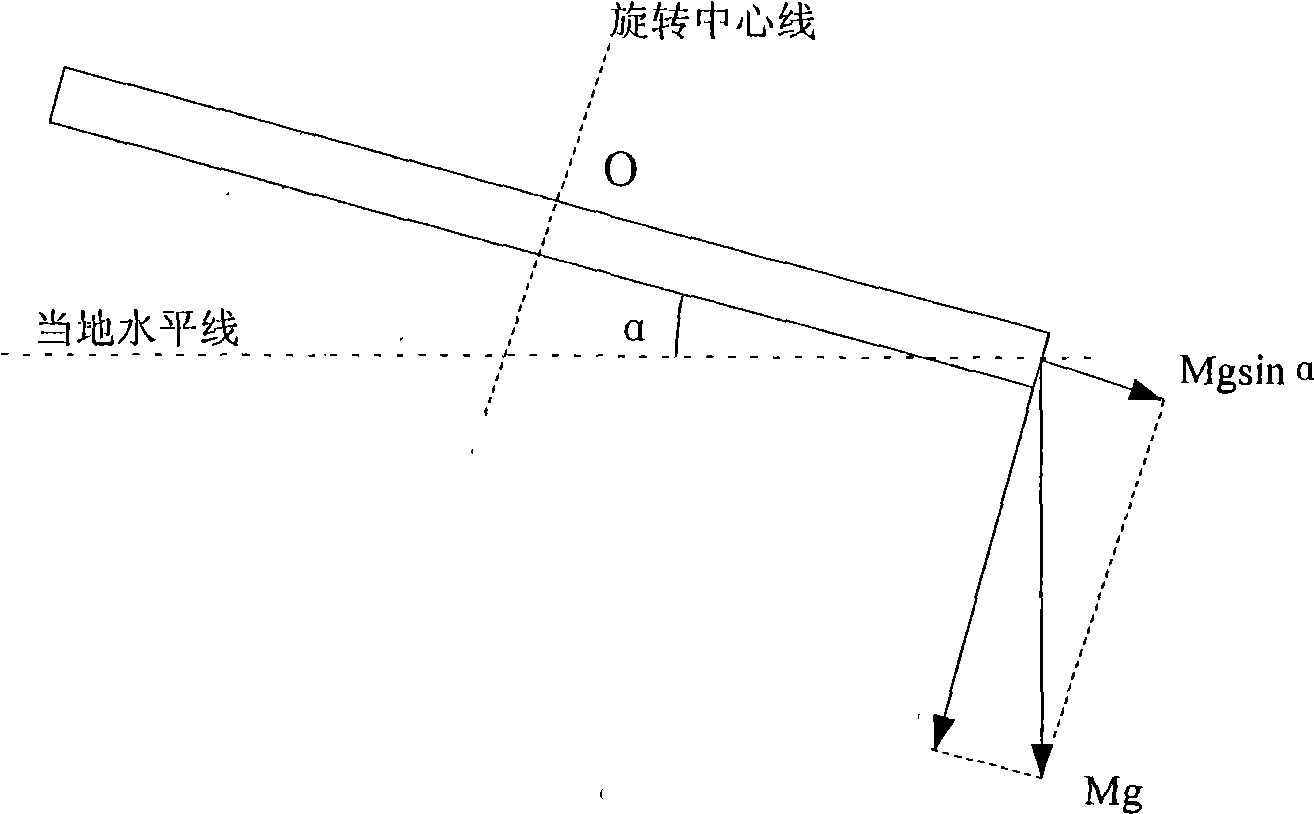

[0018] Step 1: Adjust the single-axis air bearing table to not level, measure the angle between the plane of the air bearing table and the local horizontal line with a spirit level, and record it as α;

[0019] Step 2: Make the single-axis air bearing table swing back and forth under the action of gravity, and record the amplitude and period of the swing;

[0020] Step 3: Calculate the actual eccentricity L of the center of gravity of the single-axis air bearing table and the center of rotation of the single-axis air bearing table according to the swing period;

[0021] Step 4: Place corresponding counterweights on the centerline of the recorded swing angles on both sides of the single-axis air bearing table to adjust the balance; Step 5: Repeat the above steps until the eccentricity is zero or s...

Embodiment 2

[0027] Example 2, combined with figure 1 , figure 2 , image 3 , Figure 4 , the balance adjustment method of the uniaxial air bearing platform of the present invention, the calculation method is as follows:

[0028] First, tilt the single-axis air bearing table at a certain angle. The specific operation is that there are feet or ground feet installed under the base of the single-axis air bearing table. The number is usually 3 (or more). The purpose of tilting the single-axis air bearing table can be achieved by adjusting any one of the feet up or down (if there are more than one, select any adjacent several pads to adjust up or down).

[0029] Then use a level to measure the angle of inclination α, and the specific steps are: (1) put the level on the uniaxial air bearing table, such as Figure 4 As shown, the level should be close to the outer edge of the single-axis air bearing table; (2) Record the degree of the level, denoted as a 1 , turn the single-axis air bearing...

Embodiment 3

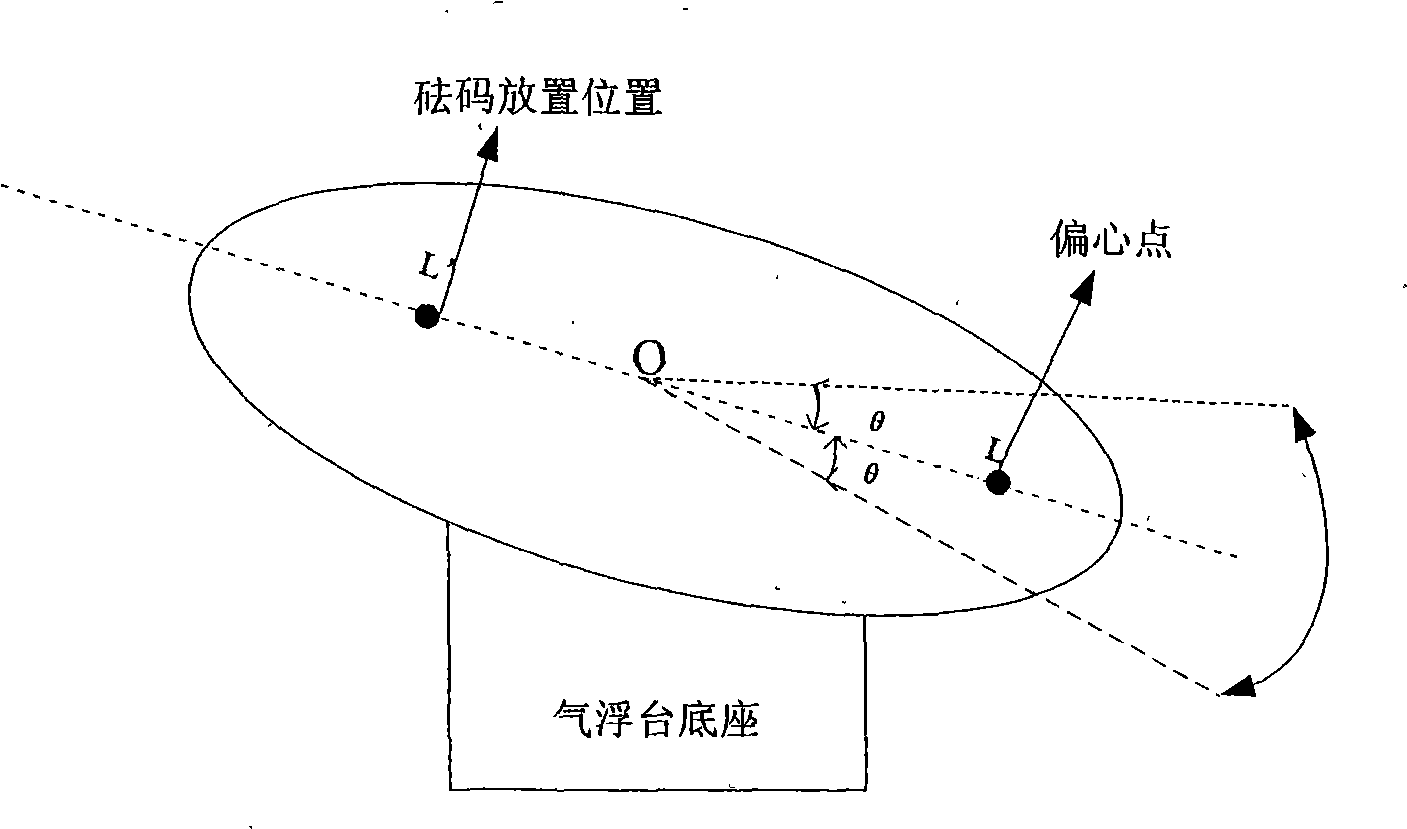

[0032] Example 3, combined with image 3 , the balance adjustment method of the uniaxial air bearing platform of the present invention, the balance weight is selected and placed as follows:

[0033] When determining the swing period and amplitude of the air bearing table, it is carried out on the downhill side, or on the heavier side, so the weight should be added to the lighter side, that is, the eccentric point and the center of rotation contralateral position, such as image 3 shown. In addition, when placing weights, place the lightest weight first, and if it does not meet the requirements, replace it with a heavier weight, and so on, step by step. When the counter weight is placed, if the test equipment has been installed on the placement point, the operator needs to be flexible at this time, that is: if the test equipment allows weights to be placed, the weights are placed on the equipment. According to the inventor With many years of operating experience, there is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com