Electrochemically active organic thin film, method for producing the same, and device using the same

An organic thin film, electrochemical technology, applied in the field of electrochemically active organic thin films, can solve the problems of difficulty in building electronic circuits and low response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

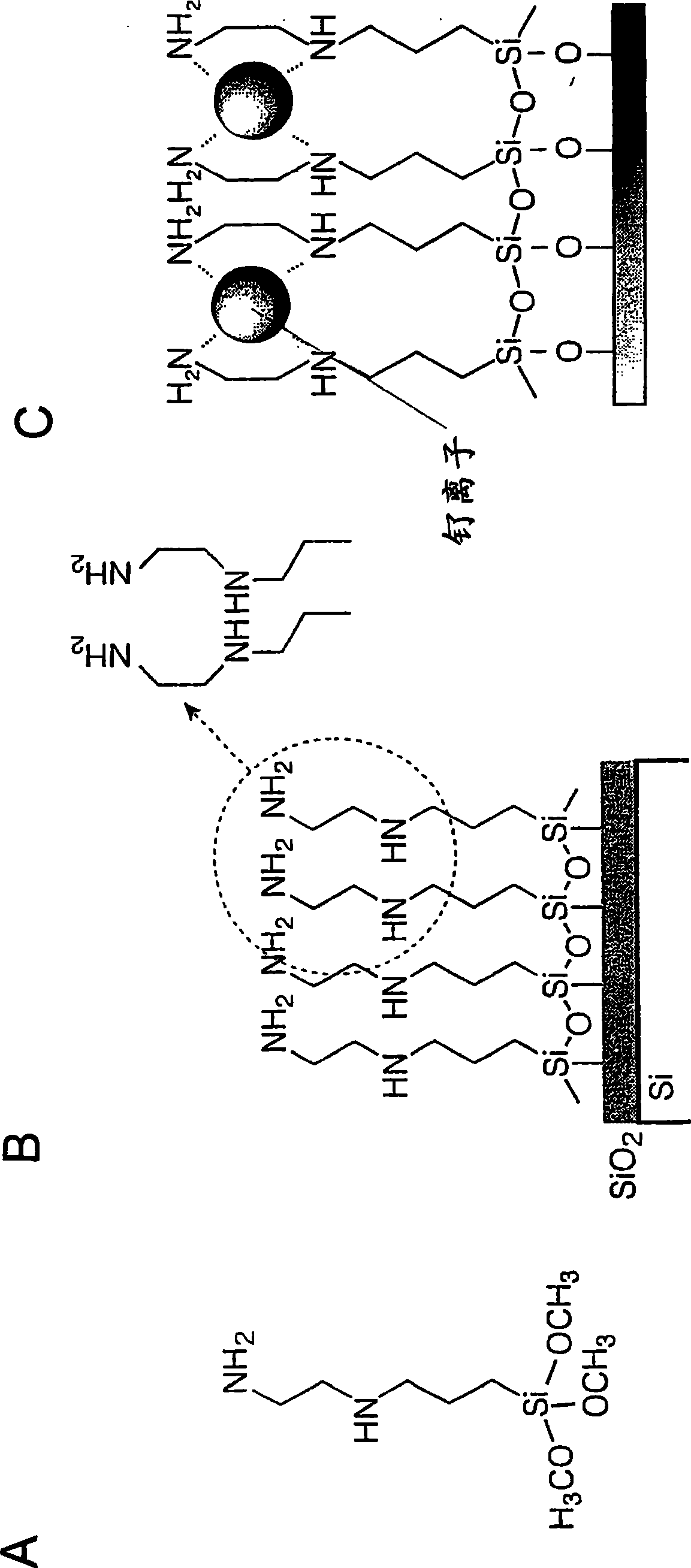

[0043] When a hydrogen-terminated silicon surface undergoes thermal / photoexcitation, the hydrogen atoms on the surface are removed and silicon radicals are generated. Through the reaction between silicon radicals and organic molecules, silicon radicals combine with organic molecules to form a monolayer. In the case of the reaction between silicon radicals and unsaturated hydrocarbons, organic molecules such as alcohol molecules or aldehyde molecules are immobilized on the silicon substrate through Si—C bonds, and a monolayer is formed. The reaction temperature is between 100°C and 200°C; however, it is very unlikely that Si-H bonds will be split and hydrogen atoms will be removed at such low temperatures. Therefore, the removal of the hydrogen atom is considered to proceed at a site where the hydrogen atom is easily removed for some reason, and the reaction is considered to proceed due to a chain reaction.

[0044] The method of immobilizing metal coordination compound molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com