A mixed refrigerant suitable for 120k ~ 150k cryogenic temperature zone

A technology of mixing refrigerants and refrigerants, which is applied in the direction of heat exchange materials, chemical instruments and methods, and can solve problems such as danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

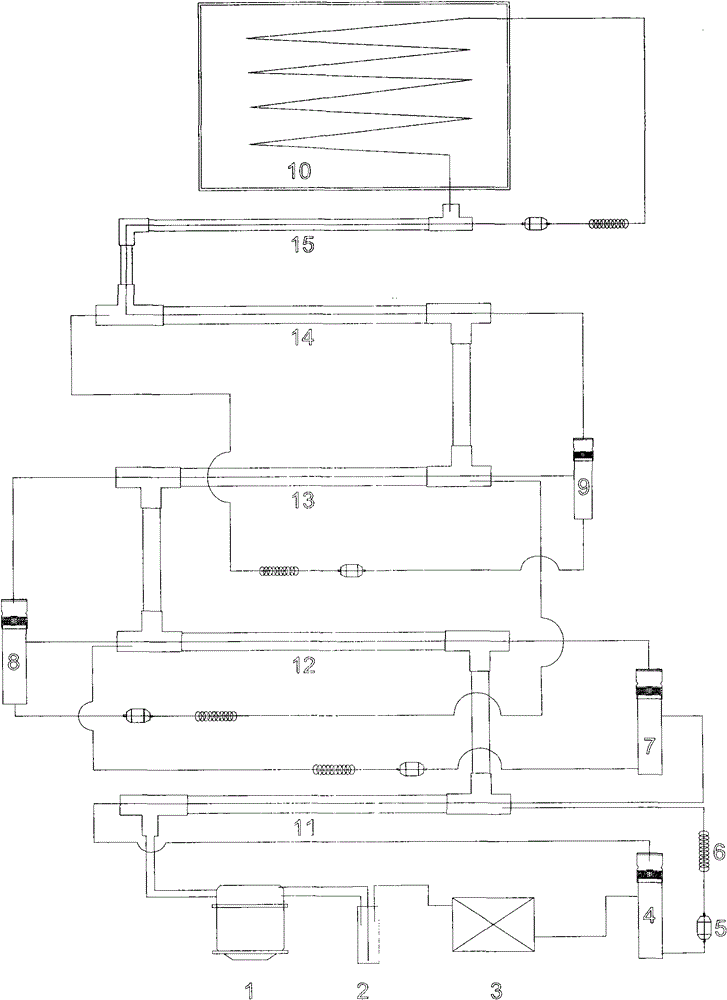

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: Configure the mixed refrigerant used in the 120K temperature zone, and the molar concentration of each type of refrigerant is as follows:

[0058] The first category: R728 accounts for 10% of the total molar concentration, and R740 accounts for 10% of the total molar concentration;

[0059] The second type: R50 accounts for 10% of the total molar concentration; R784 accounts for 5% of the total molar concentration;

[0060] The third category: R14 accounts for 20% of the total molar concentration;

[0061] The fourth category: R23 accounts for 20% of the total molar concentration;

[0062] The fifth category: R22 accounts for 5% of the total molar concentration, and the rest is 0%;

[0063] The sixth category: R123 accounts for 20% of the total molar concentration, and the rest is 0%.

[0064] The operating parameters are: condensing temperature 300K, refrigeration temperature 120K, compressor discharge temperature 380K, high pressure 220psi, low pressu...

Embodiment 2

[0065] Embodiment 2: Configure the mixed refrigerant used in the 120K temperature zone, and the molar concentration of each type of refrigerant is as follows:

[0066] The first category: R728 accounts for 5% of the total molar concentration, and R740 accounts for 15% of the total molar concentration;

[0067] The second type: R50 accounts for 5% of the total molar concentration; R784 accounts for 10% of the total molar concentration;

[0068] The third category: R14 accounts for 15% of the total molar concentration;

[0069] The fourth category: R23 accounts for 20% of the total molar concentration;

[0070] The fifth category: R32 accounts for 5% of the total molar concentration, R22 accounts for 5% of the total molar concentration, and the rest is 0%;

[0071] The sixth category: R123 accounts for 20% of the total molar concentration, and the rest is 0%.

[0072] The operating parameters are: condensing temperature 300K, cooling temperature 120K, compressor discharge tem...

Embodiment 3

[0073] Embodiment 3: Configure the mixed refrigerant used in the 130K temperature zone, and the molar concentration of each type of refrigerant is as follows:

[0074] The first category: R740 accounts for 15% of the total molar concentration, and the rest is 0%;

[0075] The second category: R784 accounts for 20% of the total molar concentration, and the rest is 0%;

[0076] The third category: R14 accounts for 20% of the total molar concentration;

[0077] The fourth category: R23 accounts for 15% of the total molar concentration;

[0078] The fifth category: R125 accounts for 3% of the total molar concentration, R218 accounts for 7% of the total molar concentration, and the rest is 0%;

[0079] The sixth category: R123 accounts for 10% of the total molar concentration, R124 accounts for 10% of the total molar concentration, and the rest is 0%;

[0080] The operating parameters are: condensing temperature 300K, cooling temperature 130K, compressor discharge temperature 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com