Reflux brazier soldering flux collection device and using method thereof

A reflow oven and collection device technology, applied in auxiliary devices, cleaning heat transfer devices, welding equipment, etc., can solve the problems of increasing maintenance time and work difficulty, affecting the production efficiency and output of customers, and achieving a good collection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

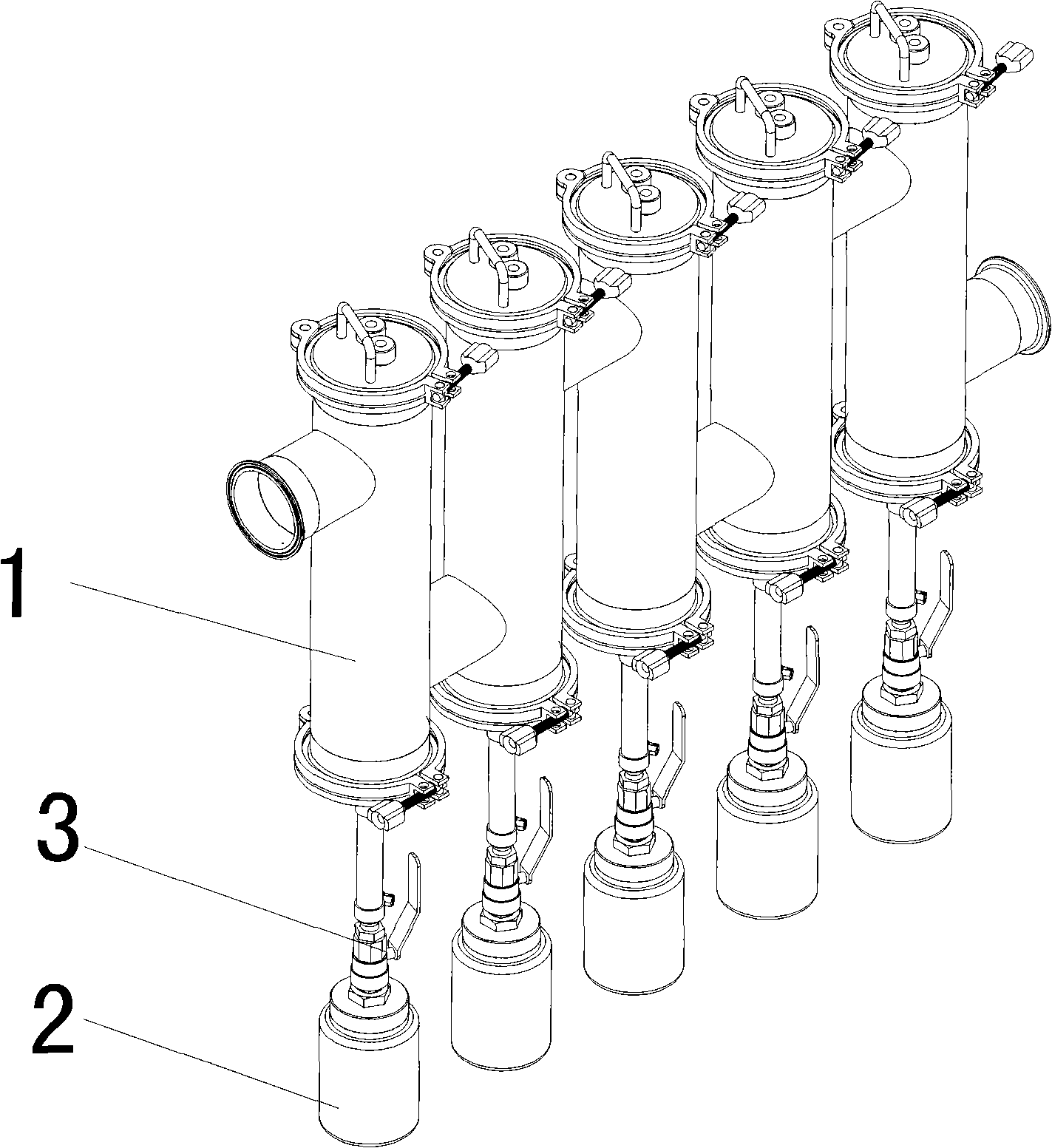

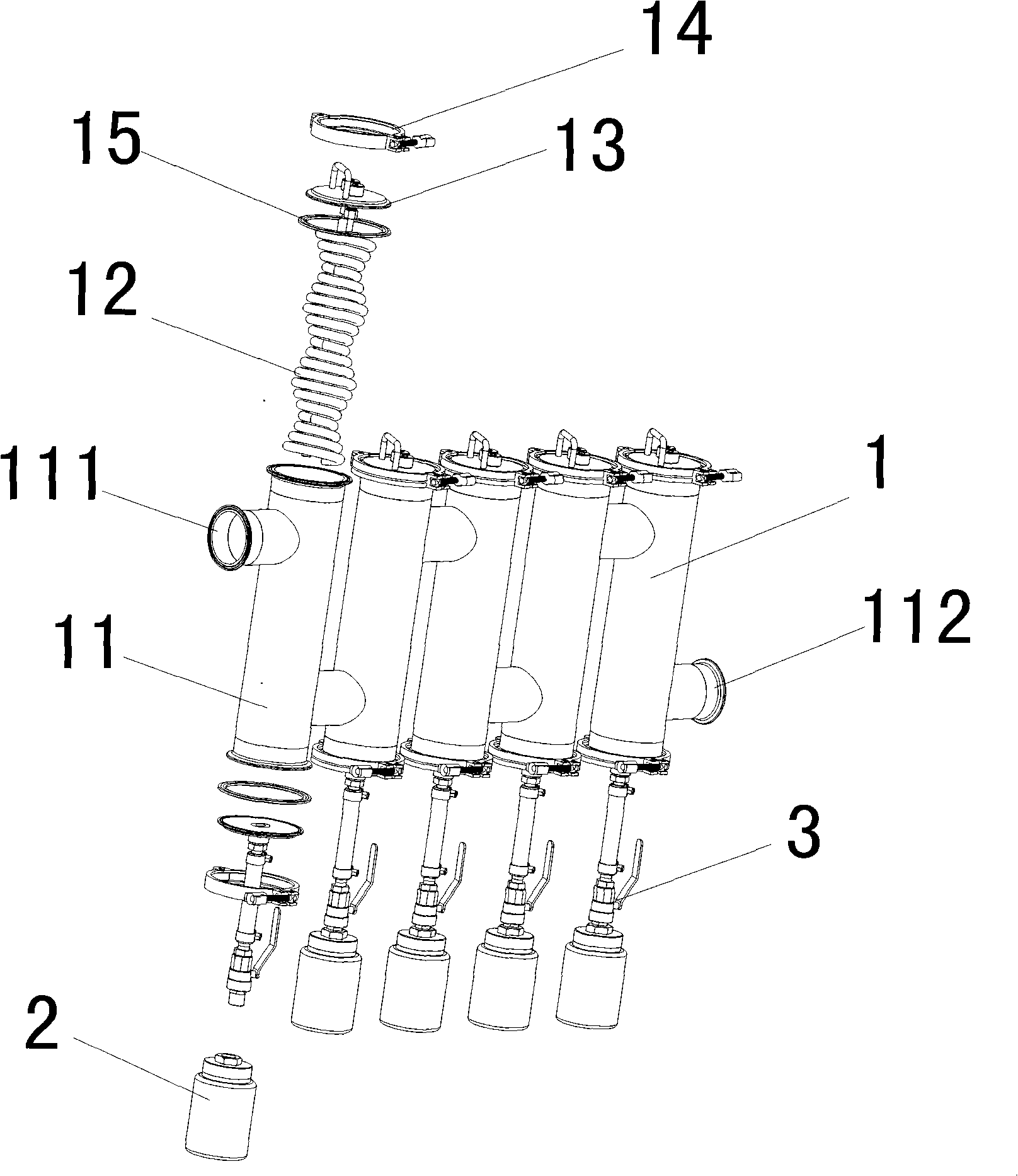

[0022] see figure 1 , figure 2 , the reflow soldering furnace flux collection device of the present invention includes at least two collection units with the same structure (5 collection units shown in this embodiment), a three-way air intake pipeline (not shown) and an exhaust pipe road (not shown). The collection units are connected in series, each collection unit includes a heat exchange column 1 and a collection bottle 2, the collection bottle 2 is arranged below the heat exchange column and connected to the heat exchange column 1 through a connecting pipeline with a ball valve 3 connected. The heat exchange column 1 includes a column body 11 and a cooling water pipeline 12 installed in the column body, and a gas inlet 111 and an outlet 112 are provided on the column body 11 . The gas inlet of the first heat exchange column is connected to the three-way inlet pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com