High-altitude portable pipeline cutting machine

A pipeline cutting machine and portable technology, applied in the directions of metal processing machinery parts, clamping, support, etc., can solve the problems of irregular project quality of pipeline opening, influence of pipeline node construction process, complicated installation operation, etc., and achieve simple and standard construction process. , light weight, convenient replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

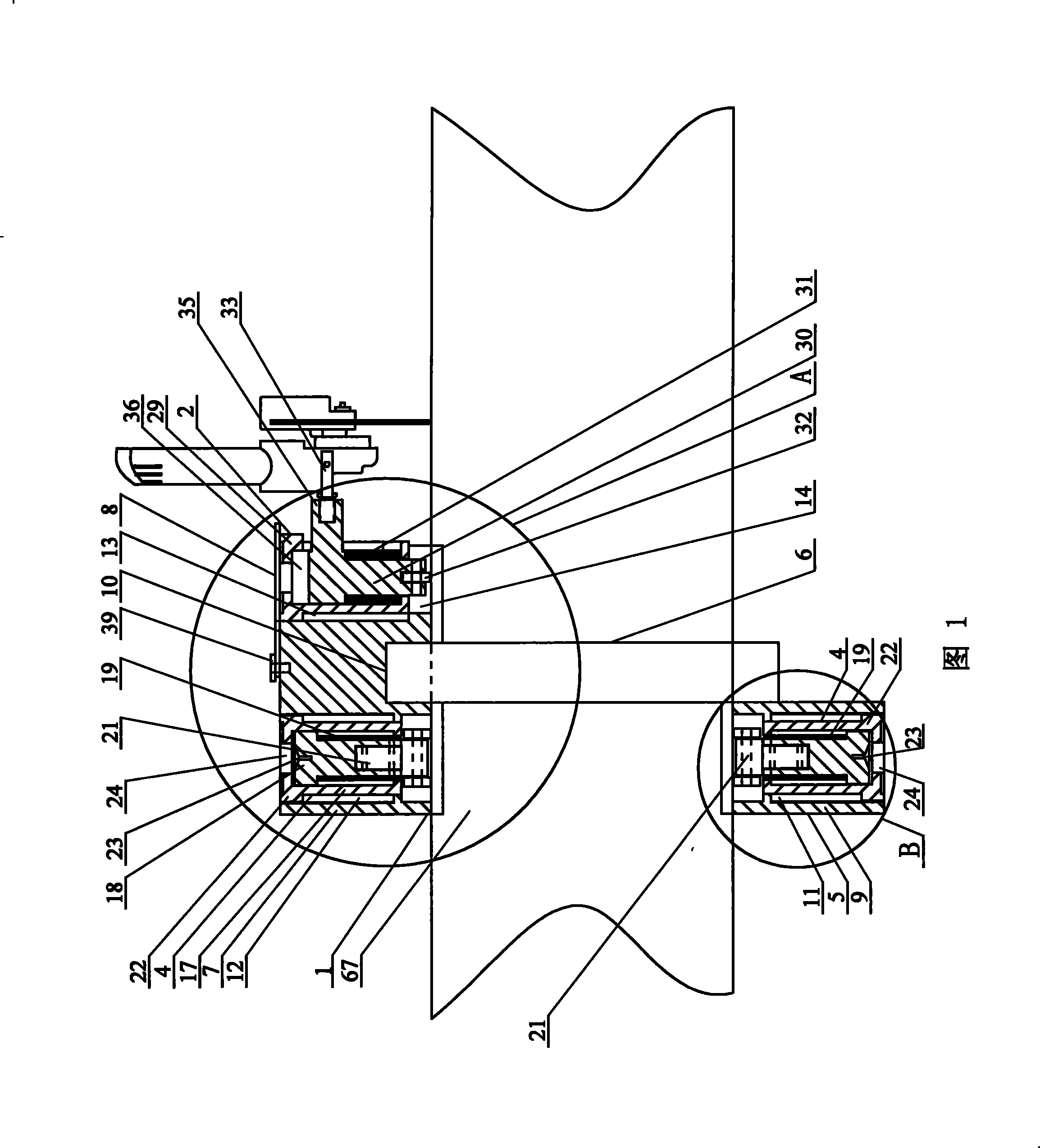

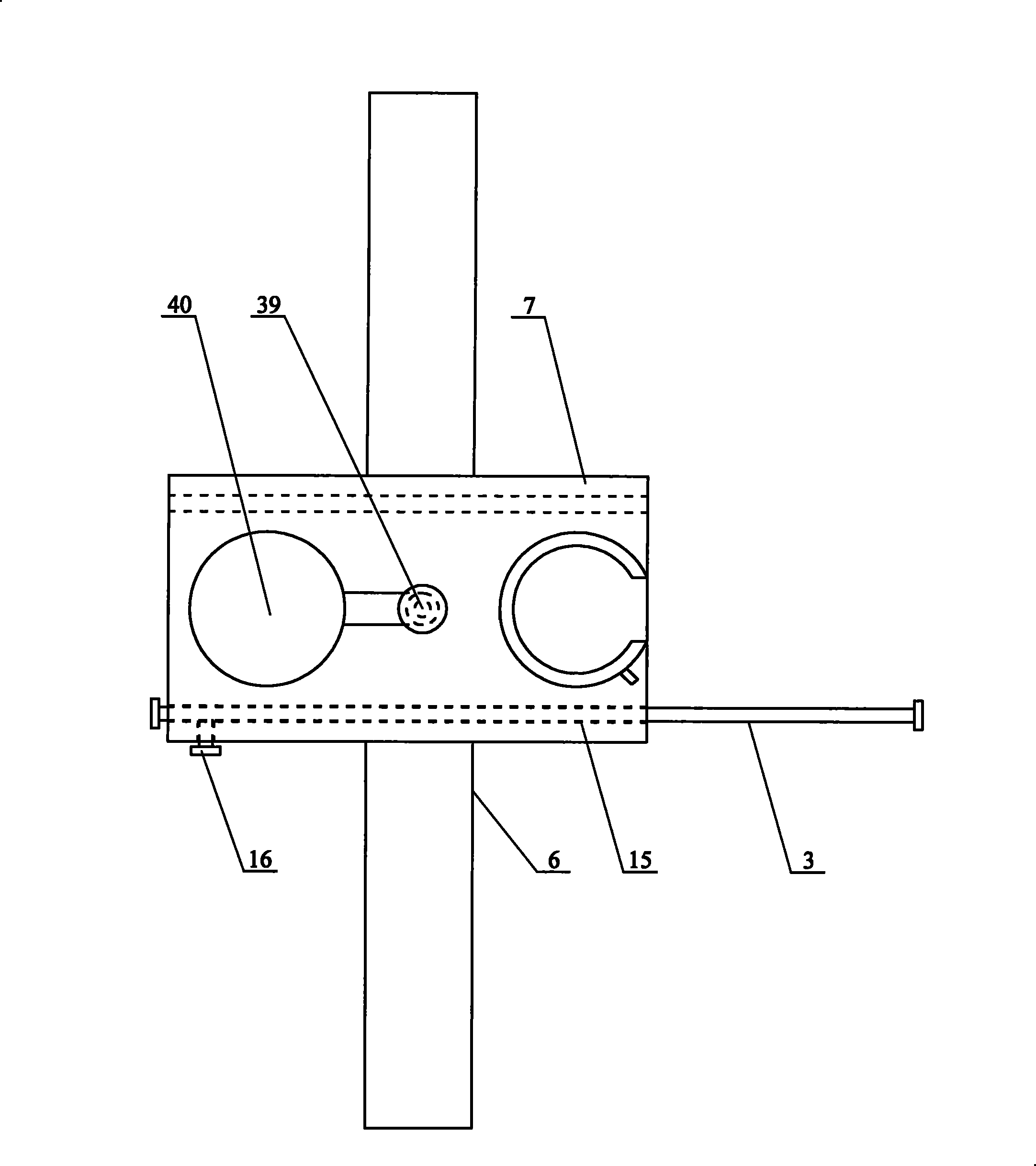

[0009] Specific implementation mode one: combine Figure 1 to Figure 11 To illustrate this embodiment, the pipe cutting machine of this embodiment is composed of a knife rest assembly 1, a knife body frame assembly 2, a positioning scale 3 and two walking mechanisms 4; the knife rest assembly 1 is composed of a knife rest body 5 and The hinged ring frame 6 is composed of; the tool holder body 5 is composed of a tool holder 7, a rotating cover 8 and a running mechanism seat 9; one end of the hinged ring frame 6 is fixed on the arc-shaped In the groove 10, and the hinged end and the open end of the articulated ring frame 6 are exposed outside, the outer side wall of the traveling mechanism seat 9 is affixed to one side of the ring end face of the articulated ring frame 6, and the inside of the traveling mechanism seat 9 Be provided with traveling mechanism chamber 11, be provided with traveling mechanism chamber 12 on the knife rest 7 corresponding with described traveling mecha...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 , Figure 7 , Figure 8 and Figure 10 Illustrate the present embodiment, each running gear 4 of the present embodiment is made up of positioning seat 17, positioning rod 18, positioning spring 19, positioning pin 20 and walking carriage 21; Threaded, the locating seat 17 that is contained in the traveling mechanism chamber 11 is threadedly connected with the inwall of the traveling mechanism chamber 11, and the locating seat 17 that is contained in the traveling mechanism chamber 12 is threadedly connected with the inwall of the traveling mechanism chamber 12, and the positioning Rod 18 is contained in the inner cavity of locating seat 17 and is slidably matched with it, and the outer wall of locating rod 18 is provided with shoulder end face, and one end of trolley 21 is contained in the locating bar 18, and trolley 21 is connected with locating bar by locating pin 20. 18 is fixedly connected, the positioning ...

specific Embodiment approach 3

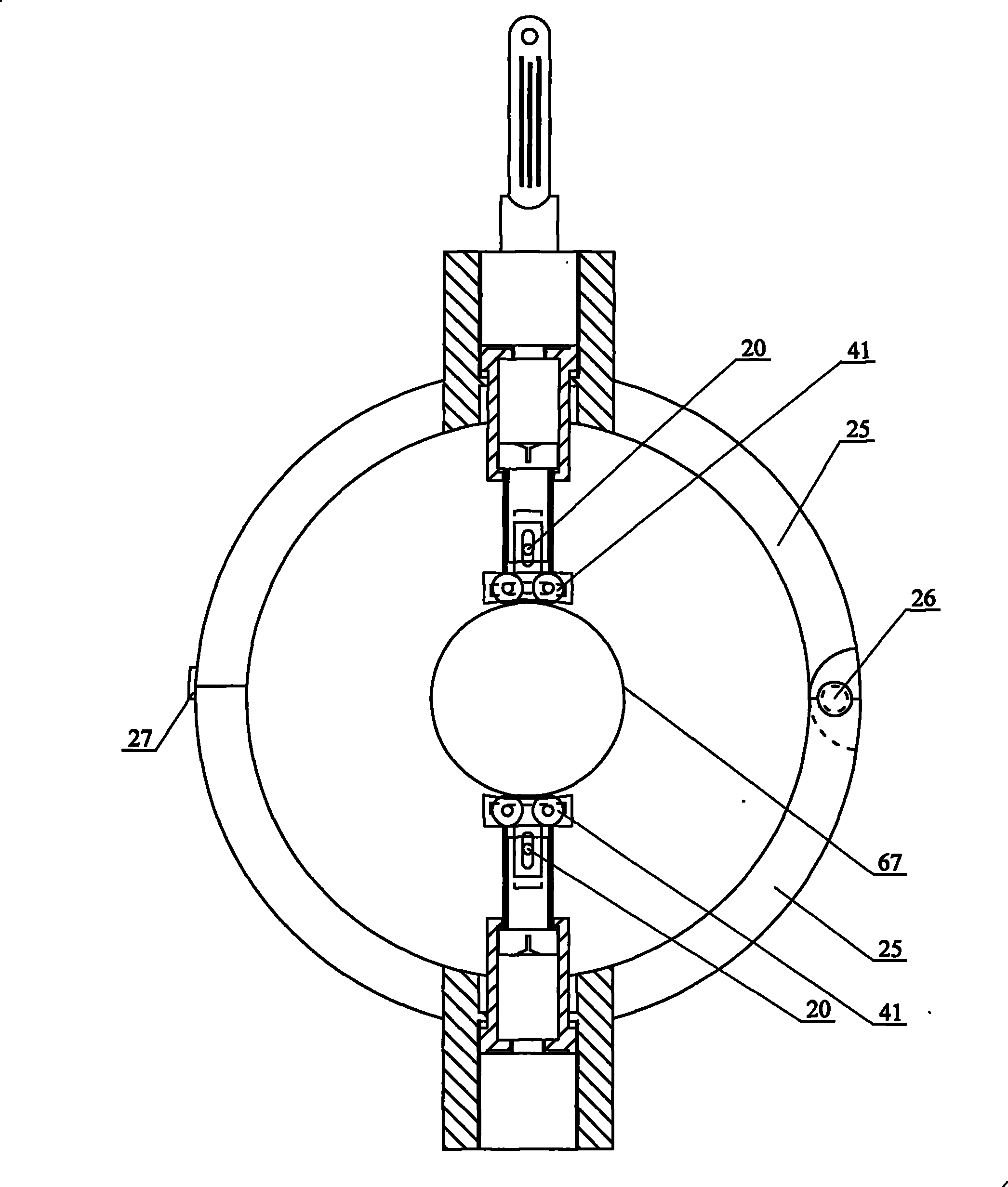

[0011] Specific implementation mode three: combination figure 1 , figure 2 , Figure 4 and Figure 5 Describe this embodiment, the articulated ring frame 6 of this embodiment is made up of rotating shaft 26, lock pin 27 and two semi-circular bodies 25; One end of each semi-circular body 25 is a stepped end 28, each The other end of the semicircular body 25 is a plane end, and the stepped ends 28 of the two semicircular bodies 25 cooperate with each other and are hinged together by the rotating shaft 26 to form the hinged end of the articulated ring frame 6, and the two semicircular The plane end of the ring body 25 constitutes the open end of the hinged ring frame 6 , and locking pins 27 are provided at the plane ends of the two semi-circular bodies 25 . So set, it is easy to open and close. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com