Tilt rotor vector propeller based on wave energy

A technology of vector thrusters and tilting rotors, which is applied to ocean energy power generation, machines/engines, underwater operation equipment, etc., can solve the problems of accelerated water flow, low efficiency, and low action sensitivity, and achieve the effect of improving steering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

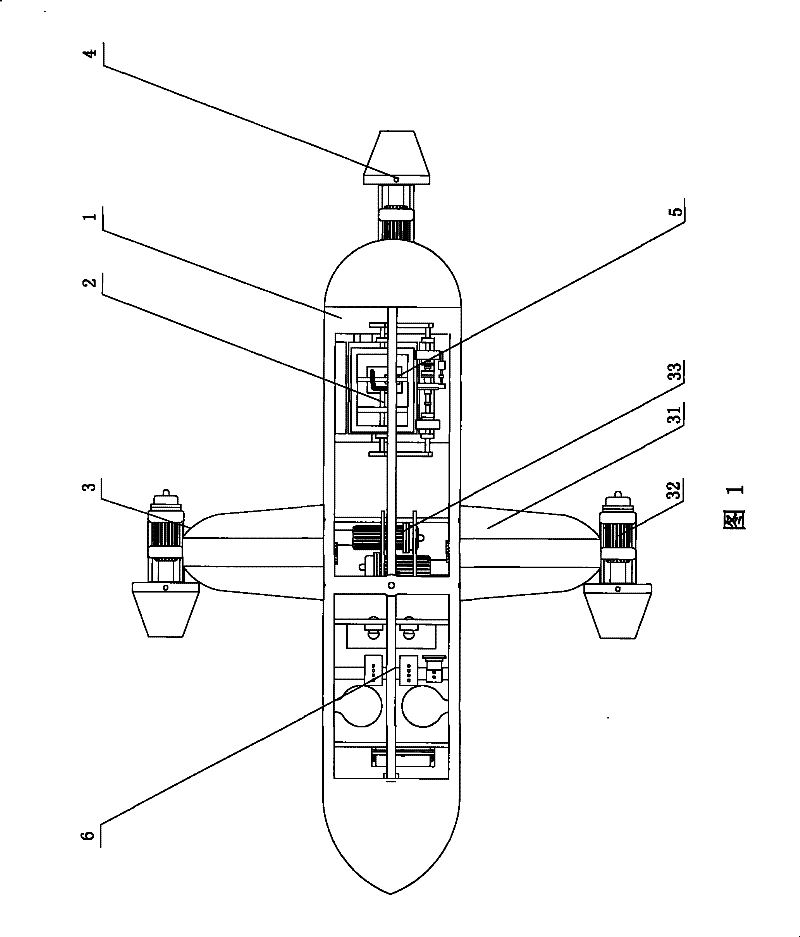

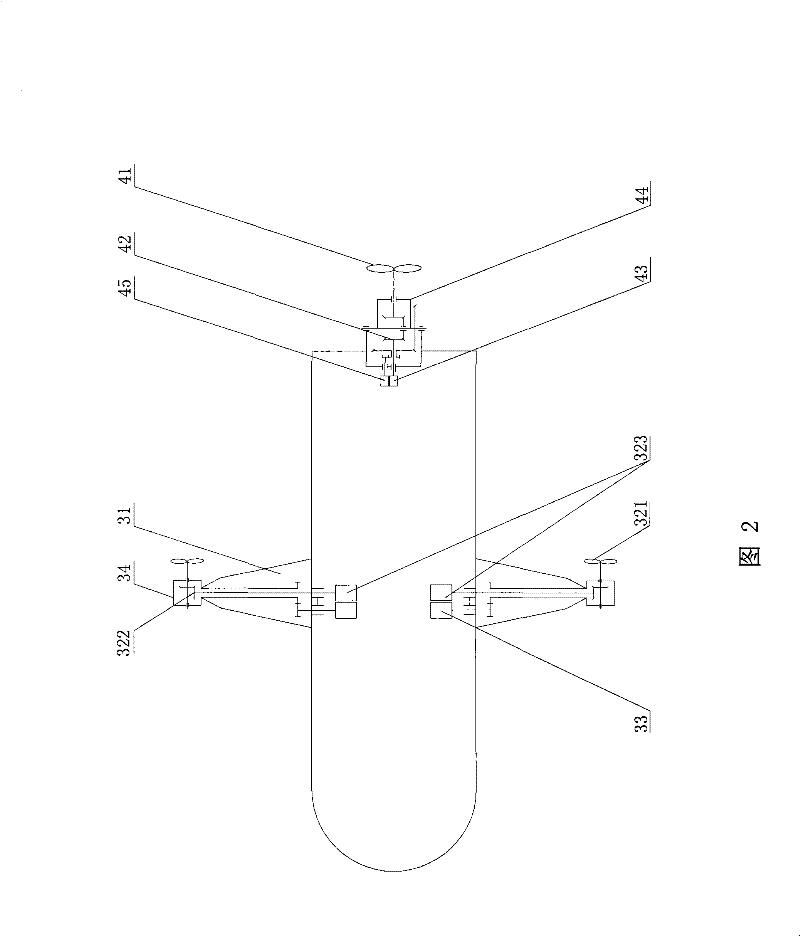

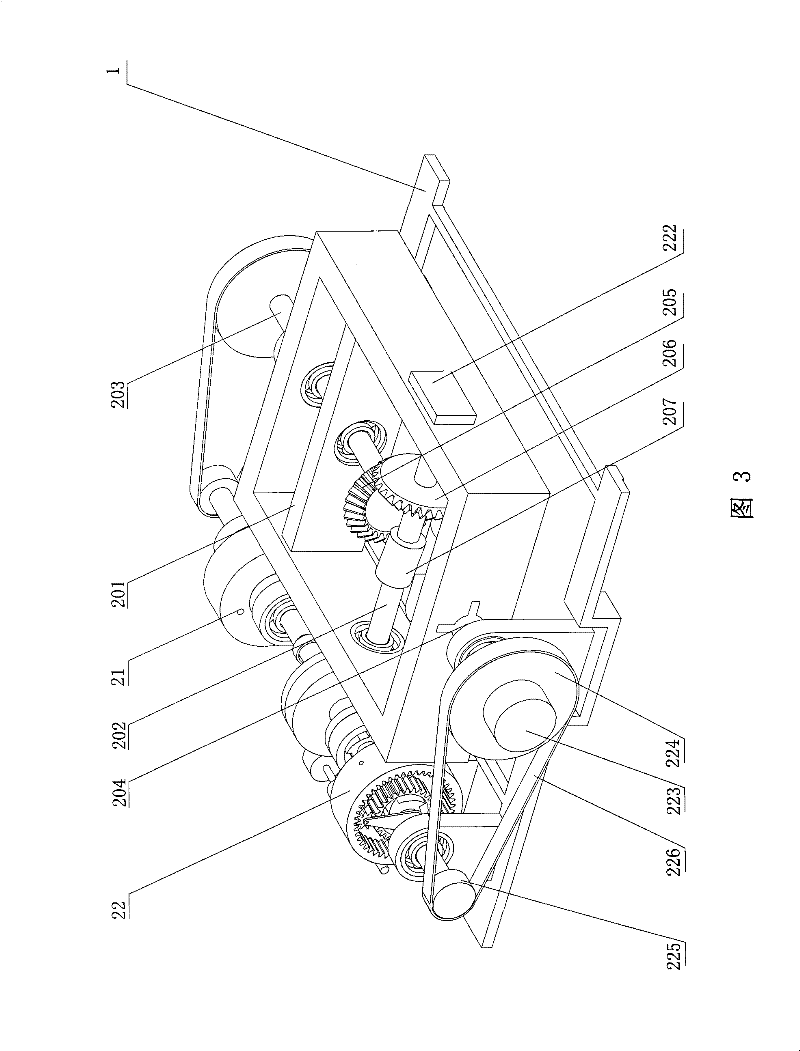

[0056] Such as figure 1 As shown, the tilt rotor vector propulsion device based on wave energy of the present invention includes a fuselage frame 1, a wave energy conversion device 2, a tilt rotor vector propulsion device 3, an empennage vector propulsion device 4, a storage battery 5 and a gliding propulsion control device 6. The tilt rotor vector propulsion device 3 and the empennage vector propulsion device 4 are the main power devices of the propeller, and both can adjust the propulsion direction. In the present embodiment, the tilt rotor vector propulsion device 3 is provided with two groups, and is respectively installed on the fuselage On both sides of the frame 1 ; one set of empennage vector propulsion device 4 is installed at the tail end of the fuselage frame 1 . The gliding propulsion control device 6 is installed on the front portion of the fuselage frame 1, and is mainly used to adjust the buoyancy of the propeller in water. The wave energy conversion device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com