Resistance metallic plate low-resistance value sheet shape resistor and manufacturing method thereof

A technology of chip resistors and manufacturing methods, applied in the direction of non-adjustable metal resistors, resistance manufacturing, resistors, etc., can solve the problems of reduced productivity, difficulty, and time-consuming, and achieve the effect of preventing the reduction of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited to these embodiments.

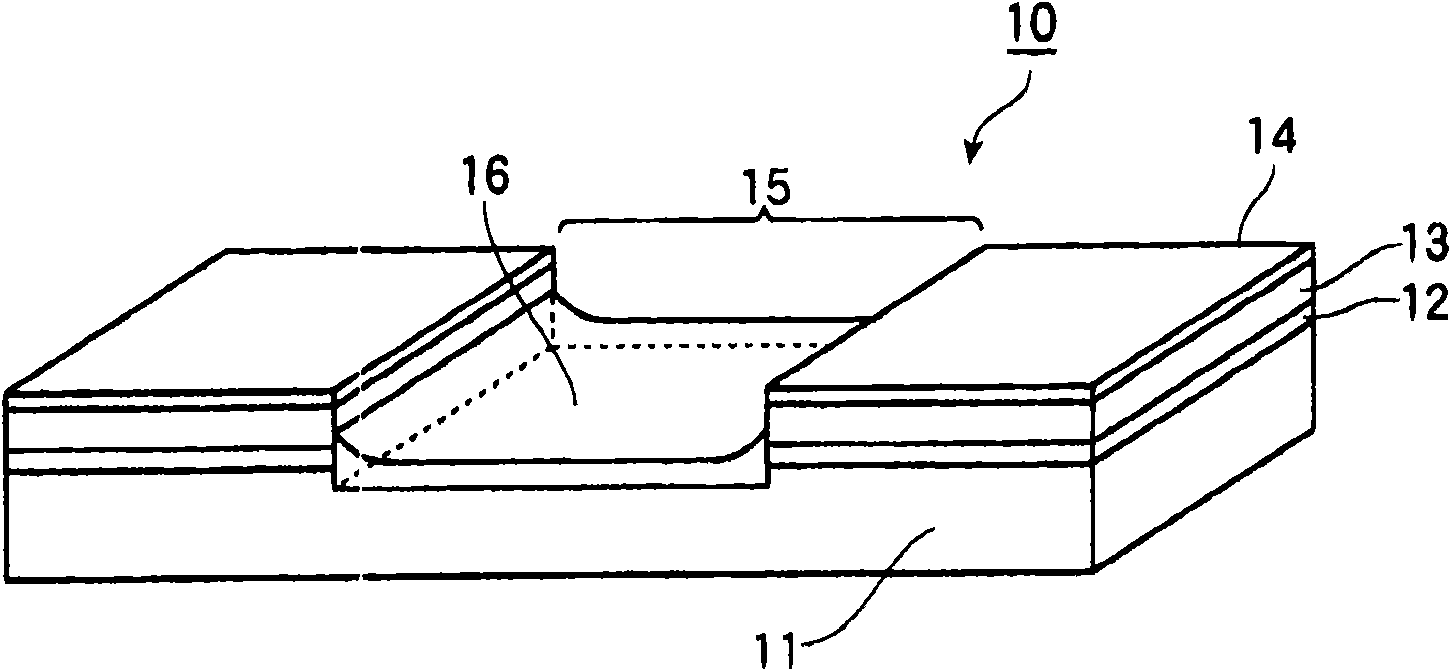

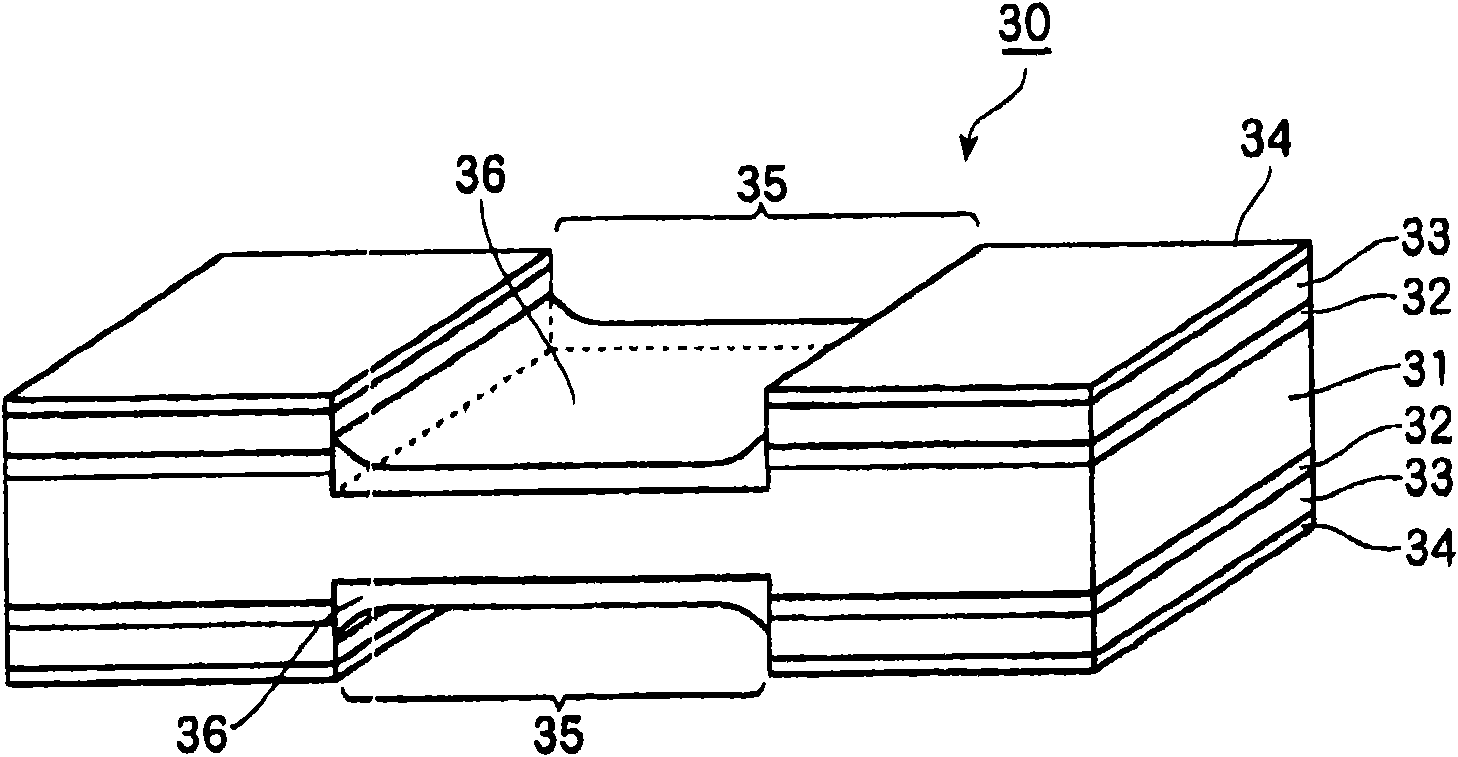

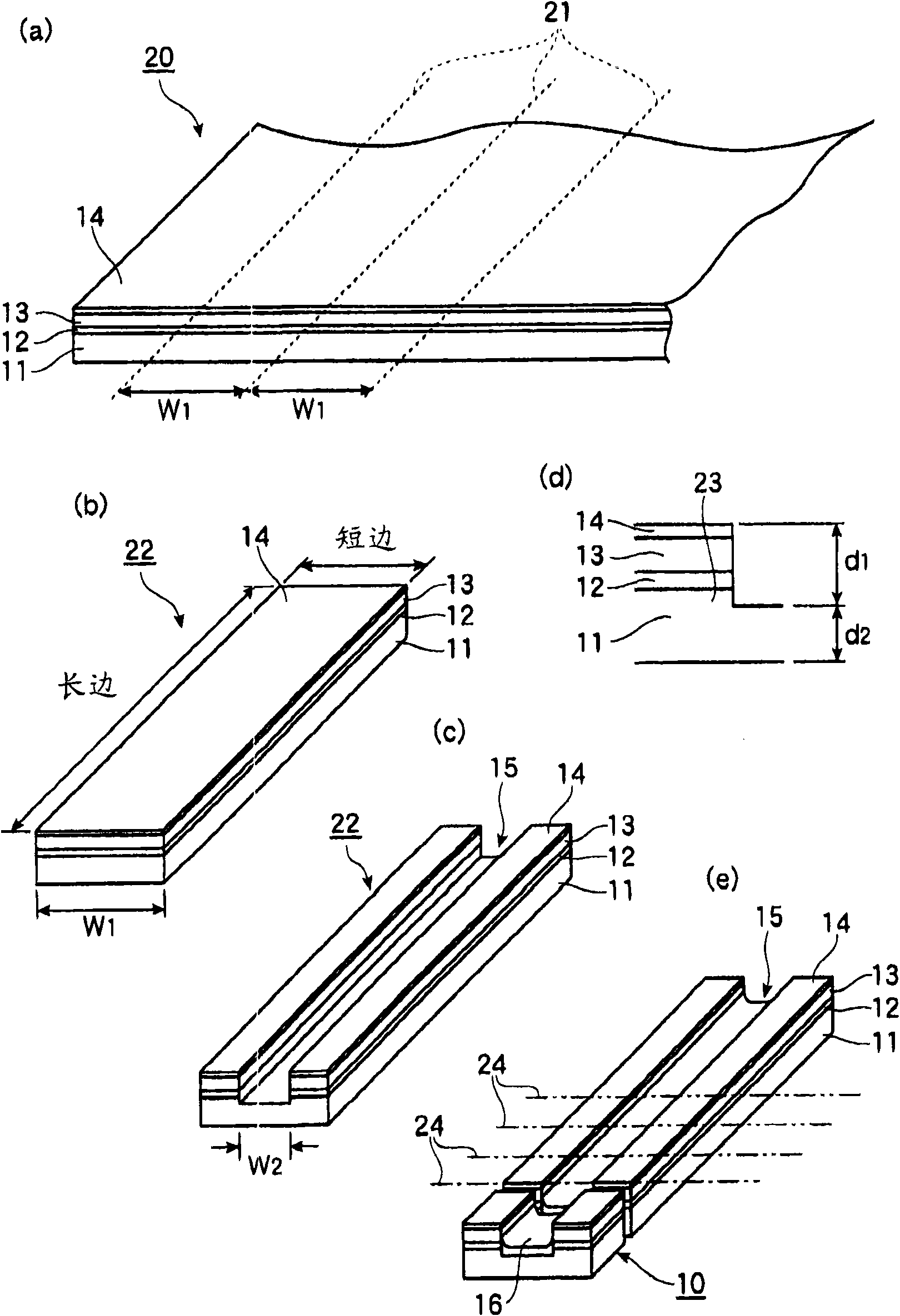

[0047] figure 1 It is a perspective view of a resistance metal plate low-resistance chip resistor 10 according to an embodiment, figure 2 It is a perspective view of a resistance metal plate low-resistance chip resistor 30 according to another embodiment.

[0048] exist figure 1 In the resistance metal plate low-resistance chip resistor 10, a copper plate 13 as an electrode is welded on one surface of the resistance metal plate 11 through solder 12, and a tin-plated film 14 is formed on the copper plate 13, and then from the substantially central portion The tin plated film 14 , the copper plate 13 , the solder 12 , and the diffusion layer of the solder 12 and the resistance metal plate 11 are removed to form a recess 15 , and a protective film 16 is formed on the bottom of the recess 15 .

[0049] exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com