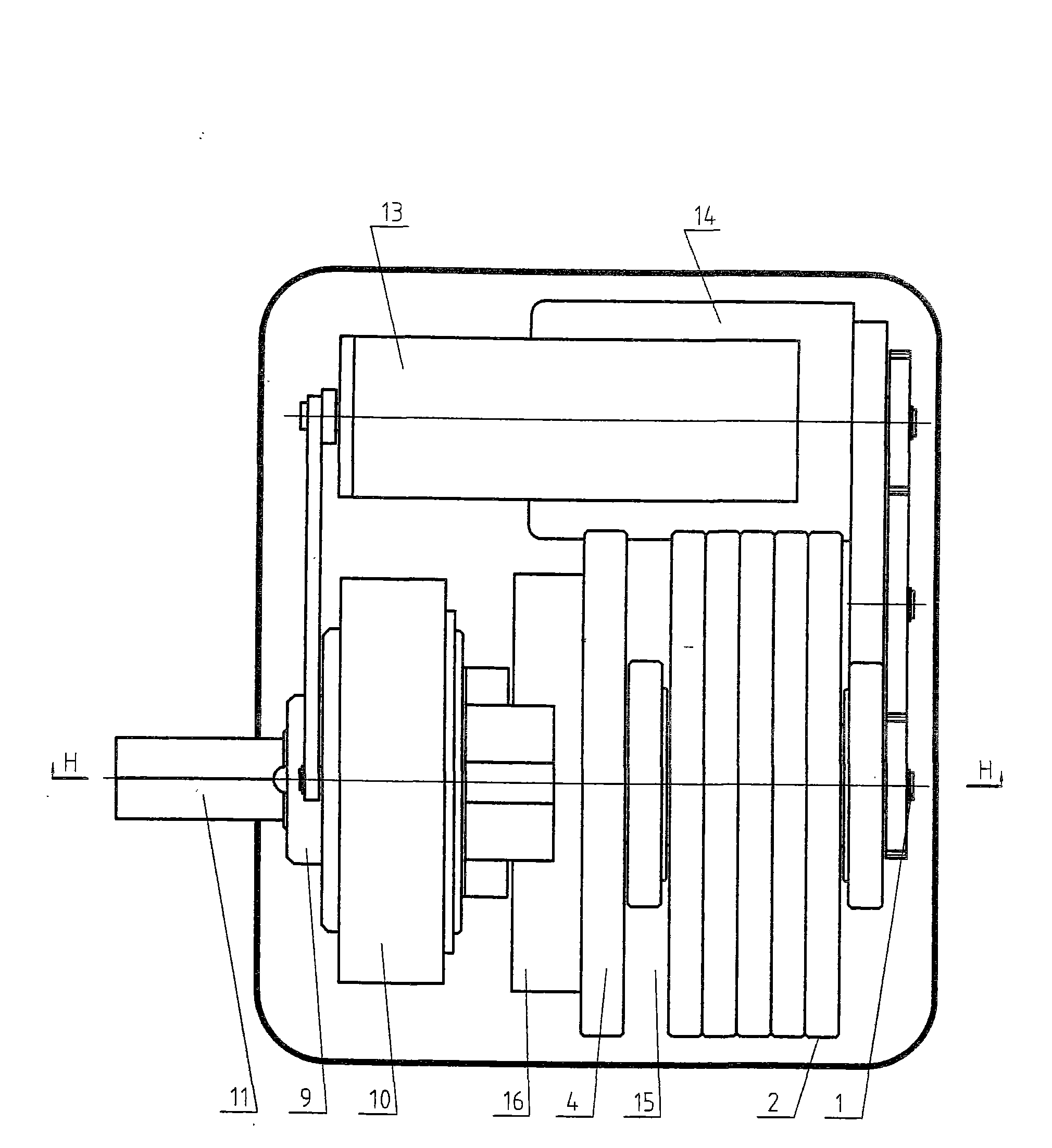

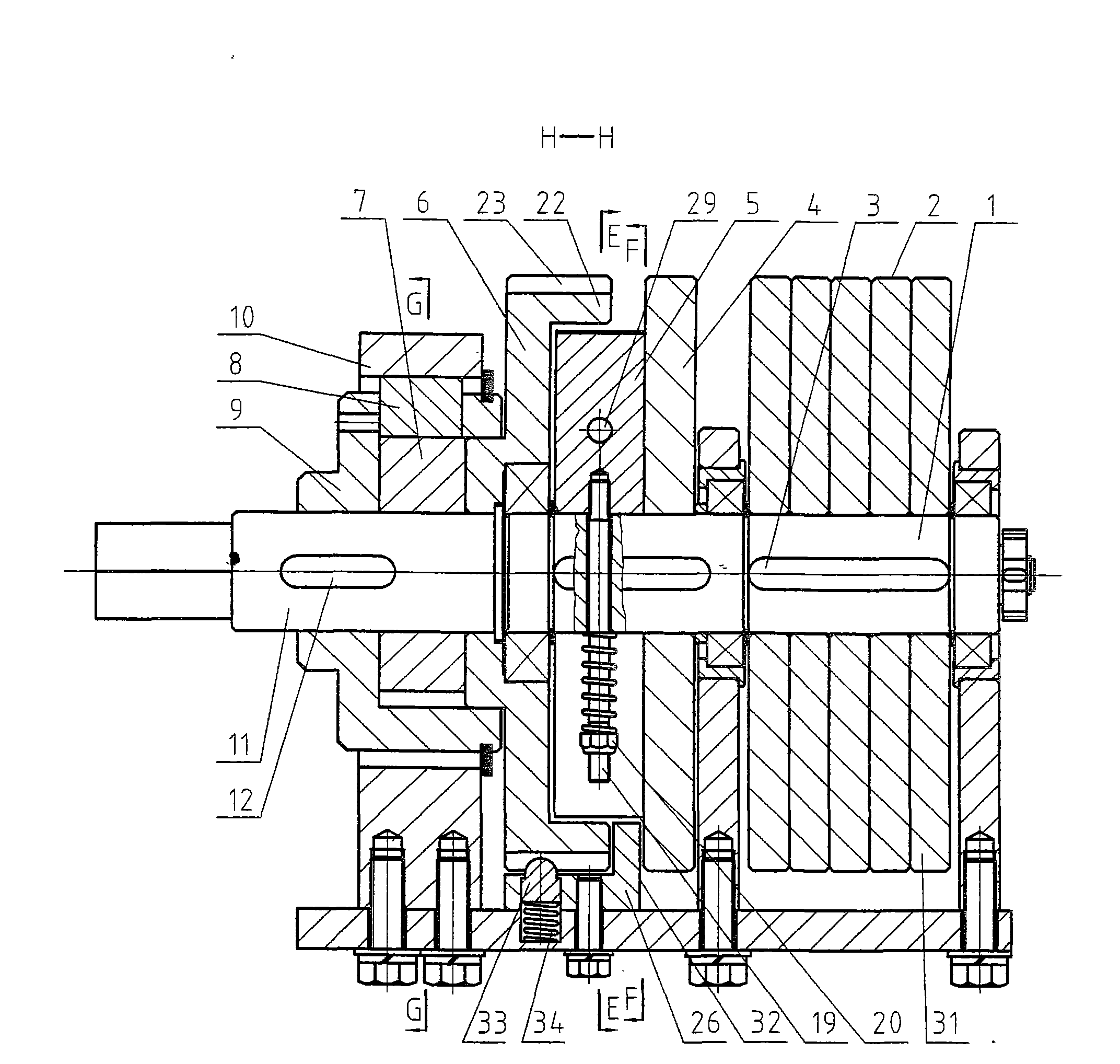

Combined electrical apparatus isolation earthing switch operating mechanism

A technology of isolating the grounding switch and the operating mechanism, which is applied to the power devices and air switch components inside the switch, can solve the problems of low indexing accuracy, complex structure, and increased failure rate, achieve firm position locking and reduce manufacturing costs. Cost and high indexing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

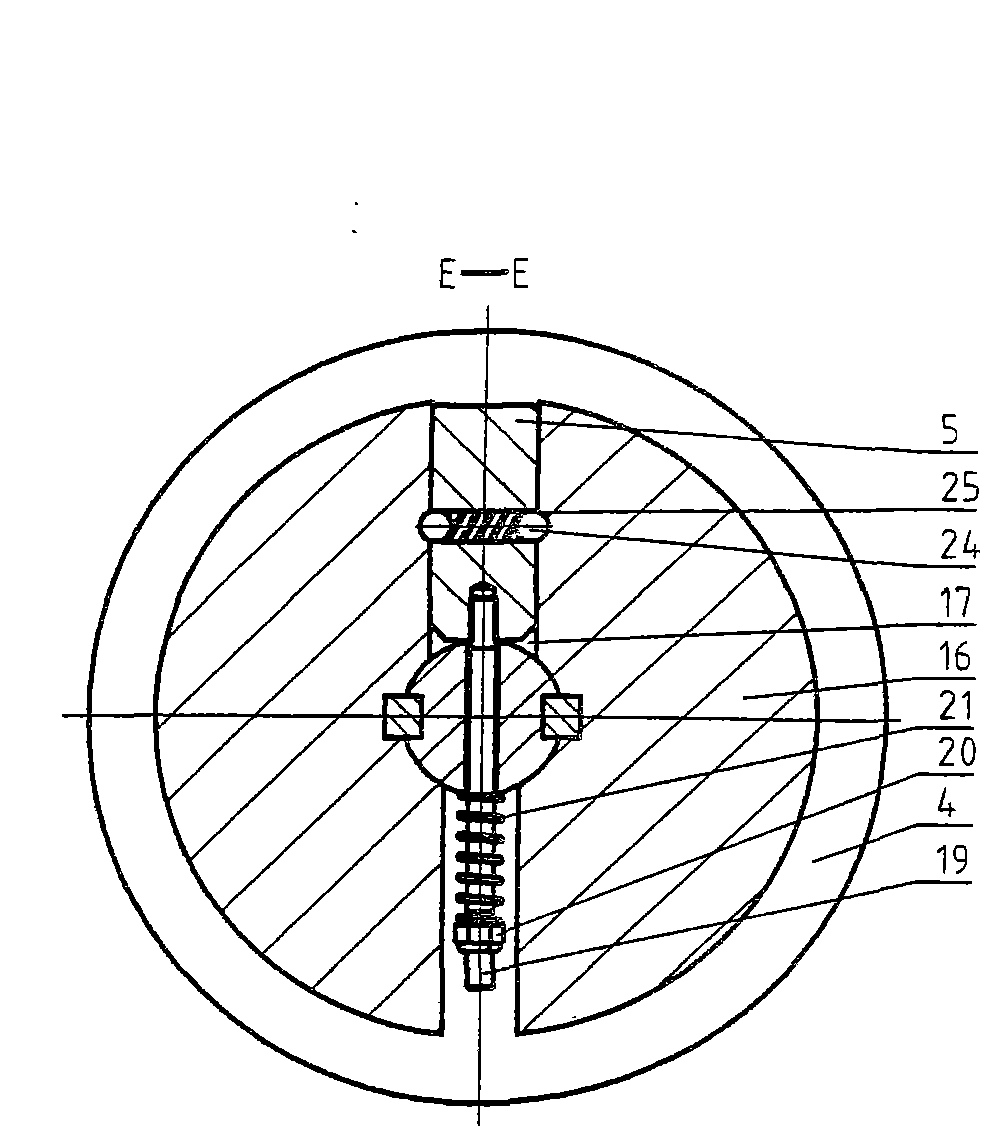

[0057] Such as Figure 11 As shown, as an embodiment in which the output shaft 11 rotates 30° when two or three stations are used, the angles between the centerlines of two adjacent movable key mounting holes 28 are 150°, 60°, and 150° respectively.

Embodiment 2

[0059] Such as Figure 12 As shown, as an embodiment in which the output shaft rotates 45° when two or three stations are used, the angles between the centerlines of two adjacent movable key mounting holes 28 are 135°, 90°, and 135° respectively.

Embodiment 3

[0061] Such as Figure 13 As shown, as an embodiment in which the output shaft 11 rotates 60° during two-station, three-station or multi-station, the angles between the centerlines of two adjacent movable key mounting holes 28 are 120° and 120° respectively. , 120°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com